Introduction

Today, changes in the human diet include not only organic fruits and vegetables but it is also an increasing demand for organic dairy products. The market of organic dairy products represents 11 % of the total world market of organic food with annual increase of about 6 % (OMSCo, 2015). The largest part of the produced goat milk is consumed as cheese and yogurt (Haenlein, 2004), whereby goat cheeses with its uniqueness in taste and texture are especially prominent (Morand-Fehr et al., 2004). Organic food production is determined by standards and rules that define the raw material, permitted additives, technology, packaging, storage and transport of products. The organic goat cheese is made from organic goat milk which should represent at least 95 % of the total components. In cheese production are also used not organic ingredients, and their share should not exceed 5 %. Preparations of genetically obtained/modified microorganisms and enzymes originating from genetic engineering cannot be used. The use of chemical preservatives should be reduced to a minimum. For milk coagulation, the usage of CaCl2 is permitted, while lactic, citric and hydrochloric acid can be used for regulating the pH of the brine. Moreover, in use are certain spices, fats, vegetable oils and natural flavors that are not obtained by organic production methods. Regarding non-agricultural ingredients, vegetable carbon (Ashy goat cheese) annatto, bixin and norbixin are allowed (EC, 2008;EEC, 1993). This technology is new and recently considered in the dairy industry.

The quality of organic goat milk comes from organic production management and from animal nutrition in organic farming. The organic milk, which contains more dry matter and nutrients represents a quality raw material to obtain products of exceptional nutritional and functional properties. The quality and technological properties of milk are best assessed by its chemical composition and physical properties, particularly the total dry matter content, fat and protein (Dozet et al., 1979). Standard chemical composition of organic and conventional goat milk has been the subject of numerous studies and thereby obtained highly opposing results.Malissiove et al. (2015) found no significant differences. On the other hand,Tudisco et al. (2010) andBovera et al. (2007) recorded higher fat content in organic milk, whilePajor et al. (2014) apart from the fat, found higher protein content and non-fat dry matter in organic goat milk.

The organic hard cheeses like artisan goat and cheese with geographical origin are often produced from raw milk in the traditional way. However, hard cheeses are now produced from pasteurized milk by adding thermophilic starter culture and with curd drying at temperatures of 39-42 °C, to form a solid consistency of cheese (Popović-Vranješ, 2015). With a variety of advanced technologies for obtaining goat cheese in different parts of the world and the significant variation in the composition of goat milk, goat cheese yields are also very variable (Park and Haenlein, 2006). A number of basic ingredients that pass from milk into cheese and whey expressed their distribution, which is particularly important in the production of traditional cheeses where special attention is paid to the exploitation of fat and protein. It affects the yield of the cheese, but also indicates the technology of cheese (Savić et al., 2015). Market goat cheese represents the primary source of income for producers of goat's milk and for these reasons efficient production of cheese for them is always more challenging compared to producers of cow's milk (Wolf, 2014).

Consumption of components used in the cheese production can be monitored through whey quality whereby different varieties of cheese have different whey quality. The differences are in specific acidity and the content of nutrients. The practice of treating whey as waste and using its nutritional value only as a livestock feed is abandoned long time ago. Whey and its preparations are now referred to as the forgotten treasures and for its unique properties; it is rediscovered and increasingly used in food industry (Krolczyk et al., 2016). Today, in the EU, 25 % of the total produced whey is used in human food, while in the USA it amounts to more than 50 % (EDA, 2016). Goat whey contains more important nutrients, possesses exceptional nutritional and qualitative characteristics, and is an essential part of every healthy meal. Commercial production of organic cheese, whey and whey protein concentrate is still at the beginning of its development and presents the possibility of obtaining a number of functional products.

The purpose of this research is to describe the production of organic hard goat cheese and whey. It also provides an overview of chemical parameters with special emphasis on the impact of organic farming to the production, quality of organic milk and derived products: cheese and whey.

Materials and methods

Samples of organic (n = 10) and conventional goat milk (n = 10) were taken directly from the goat breeders. Organic milk samples were taken from certified organic goat breeder. Goats were in the same stage of lactation and belong to the same breed (Alpine). The samples were collected during the last 3 month of lactation, arranged in the same time intervals. Analyses of milk, cheese and whey were performed in the laboratories of the Department of Animal Science, Faculty of Agriculture, Novi Sad (Republic of Serbia). Standard analysis of the chemical composition of organic and conventional goat milk was done with the MilkoScan FT + analyzer using the FTIR technique. MilkoScanTM + FT techniques were in accordance with ISO 9622 / IDF 141: 2013 and AOAC official methods 972.16. For the determination of somatic cells in raw milk FossomaticFT FC (ISO 13366-2) was used, and for a total number of bacteria BactoScanTM FC + (ISO 16297).

Cheese and whey

Goat cheese and whey from organic (n =10) and conventional goat milk (n =10) are produced in a dairy plant "Dana", Vrbas (Republic of Serbia). Basic technological parameters of hard goat cheeses that are related to the type of milk, heat treatment of milk, coagulation, cutting the curd, processing and parameters curd, salting and ripening cheeses are shown in Table 1.

After the completion of the coagulation, cooling and brining, samples were taken and analyzed. The chemical parameters as the parameter of the cheese quality were determined. The composition of cheese and whey were determined by standard methods: total dry matter with a standard method of measuring weight loss after drying (AOAC 926.08-1927), for protein Kjeldahl - Van Slyke method for determination of the total N was used (AOAC 2001.14), milk fat content was determined according to Gerber method (AOAC 933.05), lactose by Bertrand method (AOAC, 930.32), the ash by dry ashing at 550 °C (AOAC 935.42). The pH was measured by a pH meter (WTW, type ino Lab pH 720)(AOAC 981.12), and titratable acidity by Soxlet-Henkel(Sabadoš, 1996). The presence of heavy metals and trace elements were done by atomic absorption spectrophotometry (AAS) using the atomic absorption spectrometer (Perkin-Elmer, type PinAAcle 900T) (AOAC 999.11). Phosphorus was determined by spectrophotometer (PG Instruments, type T80+)(AOAC 995.11), while for Ca, Na and K flame photometry (Sherwood, type M410) was used (Kirk and Sawyer, 1991). Samples of organic goat cheese (ripening 60 and 120 days and storage 7 months) were tested for protein content by standard ISO/TS 17837:2008 method, total nitrogen was determined according to Kjeldahl standard method, soluble nitrogen by Kjeldahl - Van Slyke standard method while the coefficient of maturity was measured by Kjeldahl/Kjeldahl - Van Slyke standard method (AOAC 2001.14). The tests were done at the Department of Dairy Science, Belgrade, Serbia.

Source: Author view (Popović-Vranješ, 2015)

In all samples, the content of the amino acid (AA) was determined after acid hydrolysis using an HPLC method with diode array detector (DAD) (Henderson et al., 2000), while the determination of the free fatty acid (FA) in the cheese was done after methylation with borontrifluoride in methanol, using Shimadzu's gas chromatograph with flame ionization detector (FID) on InterCap WAX (length 30 m, inner diameter 0.25 mm, film thickness 0.25 µm) column (AOAC 996.06). Based on the obtained analytical results, the content of the analyzed components in the cheese samples was compared, considering the ripening time. The calculation of the dry matter distribution from milk into cheese and whey was carried out using Van Slyke and Price (1952) formula (taken from,Savić (2015)) and the formula for determining the amount of whey(in %) was applied, (Popović-Vranješ and Vujičić, 1997). The results were statistically analyzed in Microsoft Office Excel 10 and presented as mean, range and coefficient of variation. At a same time, the obtained results of milk, cheese and whey were analysed using Statistica 9.0 and significant statistical differences were determined using t-test. The significance level was set at p< 0.05 and p< 0.01.

Results and discussion

The quality of goat milk for cheese making

Technology that is used in the production of hard goat cheese is different from that used in the preparation of cheese from cow's milk because of the differences between goat and cow milk (Popović-Vranješ, 2015). The production of hard cheese made from whole milk possesses a number of advantages compared to production of cheeses with reduced fat content. Fat contributes to taste and flavor of the cheese (Popović-Vranješ et al., 2013).

The composition of milk is constantly changing depending on the production requirements and payment criteria, and the milk of small ruminants is rarely standardized for cheese production (Pirisi et al., 2007). Generally, the production of goat cheese can be very problematic if we take into account the varying composition of goat milk during the year, particularly of fat and protein, and as a result cheeses made from the milk of different composition cannot keep the same features throughout the year (Božanić et al., 2002).

The results of chemical analysis of organic and conventional goat milk showed the statistically significant differences (p<0.05, p<0.01) almost in relation to all ingredients, except in ash and sodium content (Table 2). The content of fat and protein amounted to 4.29 and 4.42 %, respectively, for organic, and 3.46 and 3.61 %, respectively, for conventional milk. While lactose content was higher in the conventional milk than organic one (4.18 vs. 3.53 %).

Goat milk which contains more dry matter, fat and protein coagulates faster and had firmer curd (Clark and Sherbon, 2000).Park and Haenlein (2010) stated that the level of fat in goat milk could vary from 2.4 to 7.8 %. The fat content is higher at the end of the season, and in different goat breeds. Fall milk contains 1% more fat compared to summer milk(Gelaiset et al., 2000). In addition, the impact of the breed and lactation, milk composition always depends on the nutrition(Pirisi et al., 2007). Goats in organic farming must be fed 100 % certified organic feedstuffs and minimum proportion of roughage in the ration should be 60 % (Rahmann, 2009).

DM - Dry Matter, SCC - Somatic Cell Count; CFU - Colony Forming Units, SD-standard deviation

a,bMeans within a row marked with the different letter differ significantly (p<0.05)

c,dMeans within a row marked with the different letter differ significantly (p<0.01)

Mineral substances that are present in milk in small quantities are vital in cheese making (Jenness, 1980). Magnesium takes part in the micelles formation whereas the calcium and phosphates are included in the structure of the casein complex (Popović-Vranješ et al., 2009).

Organic milk compared to conventional, deposited significantly more calcium (0.14 vs. 0.10 %, p<0.05), but with less of magnesium (171.2 vs. 226.3 mg/kg, p<0.05, p<0.01). At the same time, conventional milk was more abundant in Zn and Fe (4.316 and 2.087 mg/kg vs. 3.504 and 1.791 mg/kg, p<0.05, p<0.01), while the organic contained more Cu (0.454 mg/kg vs. 0.154 mg/kg, p<0.05, p<0.01). The high content of somatic cells can negatively affect the technological properties of milk and consequently affect the quality of the products.Kalantzopoulus et al. (2002) reported that high somatic cell count lead to a change in the milk composition, higher content of soluble protein and Na, and had an impact on the ability of the udder to produce lactose.Raynal-Ljutovac et al. (2007) added the negative impact on the speed of coagulation and cheese production, whileChen et al. (2010) showed that the number of the somatic cell count of 1 to 1.5 million had no effect on the yield but sensory properties and texture of goat cheese were reduced.

Production, quality and ripening

The technology of organic hard goat cheese should be uniform and all technological parameters need to be controlled. If we observe the parameters in cheese production such as the distribution of dry matter from milk into cheese and whey, results showed a greater value for conventional in comparison to organic cheese (56.96 vs. 48.55 %, p<0.05, p<0.01) (Table 3).

a,bMeans within a row marked with the different letter differ significantly (p<0.05)

c,dMeans within a row marked with the different letter differ significantly (p<0.01)

DM - dry matter, FDM - fat on dry matter basis, PDM - protein on dry matter basis, substance distribution=dry matter of whey /dry matter of milk x 100 (VanSlyke and Publow, 1952, taken fromSavić et al., 2015); Qw (%) = DMp-DMm/DMp-DMw, Qw-quantity of whey, DMp-dry matter of the product, DMm-dry matter of milk, DMw-dry matter of whey, (Popović-Vranješ and Vujičić, 1997).

The cheeses, which do not undergo a process of ripening, generally are poor in the dry matter, fat and protein and have a higher lactose content. Samples of 4 days old organic goat cheese have significantly higher level of moisture (61.09 vs. 59.68 %, p<0.05) while conventional contains more lactose and dry matter (7.72 vs 7.09 %, and 40.32 vs 38.91 %, p<0.05, p<0.01).Barrucand and Raynal-Ljutovac (2011) reported similar levels of dry matter in the range of 37 to 46 g/100 g in 4 days old goat cheeses. Regarding the fat and protein content on dry matter basis obtained results did not have significant differences (37.01 vs. 37.10 % and 39.55 vs 38.44 %, p<0.05, p<0.01). The calculated amount of whey obtained from conventional milk was 84.48 % and for organic 79.22 % (p<0.05, p<0.01).Popović-Vranješ and Vujičić (1997) suggested that the actual data relating to whey were always lower than the theoretical values due to losses incurred during production. Samples of hard organic goat cheese stored for a period of 7 months had an average composition of 28.80 % protein, 30.17 % fat and 0.62 % lactose (Table 3).

Ripening of hard cheese takes several months, and with the creation of a natural crust it gets from delicate, fresh, gentle taste to milk and nuts taste (Popović-Vranješ et al., 2013). During cheese ripening, numerous physical-chemical changes are carried out which form a final cheese appearance and flavour. Biochemical changes during cheese ripening can be divided into two groups: primary (proteolysis, lipolysis and metabolism of residual lactose) and secondary (metabolism of amino and fatty acids). Primary are responsible for basic changes in texture while secondary form the final taste and smell of cheese. In cheese, more than 200 different volatile components can be found (Mikulec et al., 2010). The unique taste of cheese is the result of a complex balance between volatile and non-volatile chemical compounds from milk fat, protein and carbohydrates that appeared during cheese ripening (Fox and Wallace, 1997).

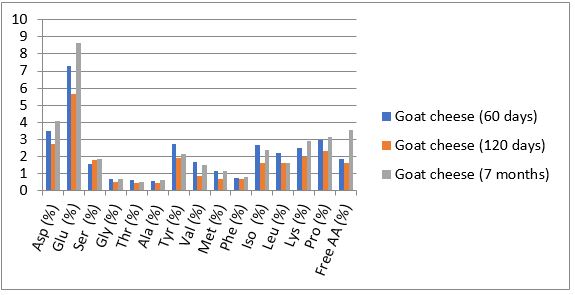

Proteolysis in cheese directly affects the development of aroma and flavor of the cheese creating amino acids and peptides, whereby some can cause disadvantages in taste and changes in pH and texture (Fox et al., 1993). It is known that certain amino acids play an important role in flavors development, for example arginine affects bitterness, whereas proline, serine, and asparagine affect the sweetness (Izco and Torre, 2000). Changes in the content of amino acids (%) during ripening and storage of organic hard goat cheeses are shown withFigure 1. Variations of quantitative relationships among free AA occurred as a result of a very complex enzymatic and microbial processes. Achieving maximum quantity of AA is in accordance with the highest degree of cheese age. The content of some AA and their total amount in the samples of cheese vary in all periods of ripening and storage that with regard to the content and accumulation of AA can be considered as unbalanced process. If we consider the content of essential AA in goat cheese, it can be said that the contents of threonine, tyrosine, valine, and isoleucine, decreased, whereas methionine, phenylalanine and lysine, showed a tendency to increase.

Also the content of some non-essential AA was different and the results confirmed the findings of extensive research regarding the accumulation of free AA in the ripening process of various cheeses. It was concluded that in relation to the initial phase of ripening, the amount of free AA had constant but unequal rise, with variations in very wide limits (Miletić, 1966 (a,b,c);Miletić, 1969).

In addition to taste, milk fat is an important factorof cheese softness and meltability. FA released in the process of cheese ripening and storage also showed variations in their quantity (Table 4).

CV - coefficient of variation

Regarding saturated FA content in organic goat cheeses, myristic, palmitic and stearic acid were dominant while oleic acid was primary as unsaturated FA. Similar results were also established in study byKravić et al., (2012) where 65 % of total fatty acids in goat cheese were palmitic, capric, myristic and oleic acid. In cheese ripening, the content of myristic acid showed a decrease while stearic acid was increased. It was noted that over time the content of caprylic and capric fatty acids was reduced, while the highest variation in content was in case of linoleic and arachidonic acid (CV of 75.51 and 40.00 %, respectively). The most stable and with the slightest deviation were myristic and oleic acid (CV of 3.86 and 4.92 %, respectively).

As a true indicator of cheese ripening levels, ratio of soluble and total N (also called as coefficient of cheese ripening) can be used. Cheeses are different depending on the production technology and ripening conditions and they also differ from each other due to the extent of proteolysis and other changes that occur during the ripening period. Different content of soluble N (a widely-used proteolysis index) occurs because of the difference in moisture content, pH value, the ripening duration and curd drying temperature. In monitored samples, coefficients of ripening increased during the cheese ripening and storage time, from 12.87 to 24.56 (Table 5).

CV (%) coefficient of variation

Content of soluble N and coefficient of ripening had a significant change in values and higher coefficients of variation (34.40 and 26.30 %) in relation to the content of nitrogen and protein (8.64 and 8.66 %, respectively). These results are in accordance with research bySlaveska et al. (1990).

Goat whey quality

Whey as a by-product of cheese production has a very variable composition. In the whey passes 50% of milk solids: mainly lactose and whey proteins as a whole, water-soluble minerals, and vitamins B complex, while vitamin C is already degraded during cheese production(Tratnik, 2003). In hard cheese production, intensity of curd cutting is significantly higher compared to soft and semi-hard cheeses and thus loss of dry matter and its transition in whey is higher as well. Also, during the reheating process which is typical for the production of hard cheeses, stirring and prolonged mechanical impact and the temperature effects results in a greater distribution of dry matter in whey (Srbinovska et al., 2001). Acidity is an important indicator of whey quality. Whey obtained after the coagulation of casein using enzymes is called sweet, while on the other hand, acid whey is the result of acid precipitation of casein. Different types of whey contain different ratios of minerals, protein and lactose, and may possess different functional properties (Pandya and Ghodke, 2007).

Analysis of whey in research carried out byDozet et al. (1978) showed that the smallest fat and protein loss was found in milk containing high fat content, while in the production of cheese with low fat, the whey containing highest amount of protein was developed.

Based on the results of the whey composition variability comparison, it can be concluded that the largest deviations were found in case of acidity (ºSH), protein and fat (CV of 40.78, 36.84 and 47.50 %), which indicated that the production technology of whey was not uniform and that the milk quality was different (Table 6).

The quantity of minerals in whey was highly variable due to different biochemical processes in cheese technology. Whey contains high amounts of soluble mineral nutrients, particularly the acid and casein type. Generally, the difference was associated with the amount of calcium and phosphorus, which were in form of a soluble calcium-phosphate (Tratnik, 2003). This depends on the whey pH and the point where the whey and curd are separated. This is the moment when the mineral composition of the cheese and the remaining lactose are largely determined. In case of cheeses such as protected designation of origin (PDO) and regional types of traditional cheeses, cheese production method effects the original milk differently and therefore mineral composition varies widely depending on the level of acid production and pH value of the whey (Lucey and Fox, 2014).

Considering macro elements,the highest deviations in the samples were found in case of Ca (44.44 %), while regarding trace elements, the highest variations were observed in case of Zn and Cu (29.09 and 44.60 %, respectively). The smallest differences among whey samples were related to the content of ash and K (5.26 and 4.76 %, respectively).

SD - standard deviation, CV - coefficient of variation, minimal (min) and maximal (max) values of variables

In all samples the presence of Pb was recorded and ranged from 0.234 to 2.340 μg/kg, which was in compliance with European regulation (EC/1881/2006). On the other hand, Cd was not detected (Table 6). Comparing the samples of organic to conventional whey, the average dry matter content was similar and amounted to 6.38 % (organic) and 6.40 % (conventional). However, the differences existed regarding the total protein content which was significant higher in organic whey samples (1.43 and 0.52 %, p<0.05, p<0.01). Lactose represents the largest proportion of whey and was more present in the conventional whey (3.56 vs. 4.51 %, p<0.05, p<0.01). Moreover, conventional whey possessed more Pb (1.169 vs 0.662 µg/kg, respectively), but the difference was not significant (p<0.05, p<0.01), and likewise the average content of other minerals.

Conclusion

Technology development of organic goat hard cheese requires adjustment in production with organic production standards and established normative. The quality of organic goat milk is mostly derived from the production management and goat nutrition that should allow obtaining the raw material without the presence of antibiotics, pesticides and heavy metals. Investigated organic goat milk samples contained significantly more dry matter, fat and protein (13.14 vs. 12.06 %, 4.29 vs 3.46 %, and 4.42 vs. 3.61 %, p<0.05, p<0.01) and from that point it is more suitable for the production of hard cheeses. At the same time, in comparison with conventional milk, hygienic quality of organic milk was significantly poorer (p<0.05, p<0.01). Therefore, there is need to find a way how to improve the hygienic quality of the organic milk.

Organic goat cheese, aged 4 days contained significantly less dry matter (38.91 vs. 40.32 %, p<0.05, p<0.01) while the fat on dry matter basis was almost equal (37.01 vs. 37.10 %). The content of certain amino and fatty acids, as well as their total amount in the hard cheese samples, varies at all stages. Achieving the maximum amount of amino acids in analyzed cheeses was in accordance with the highest degree of ripening. Regarding the content of fatty acids, the largest variation was observed in case of linoleic and arachidonic acids (75.51 and 40.00 %, respectively), while myristic and oleic acids were quite constant in the process of cheese ripening and storage (CV of 3.86 and 4.92 %, respectively).

There is a possibility of producing hard goat cheeses of controlled and consistent quality, if there is market demand, through the process of introducing standardization of technological process and the ripening conditions. Investigation of the whey quality confirmed the assertion of their unequal and variable composition. Organic whey contained significantly more total protein, but regarding the content of dry matter there were no significant differences (6.38 and 6.40%, respectively, (p<0.05, p<0.01)).