Introduction

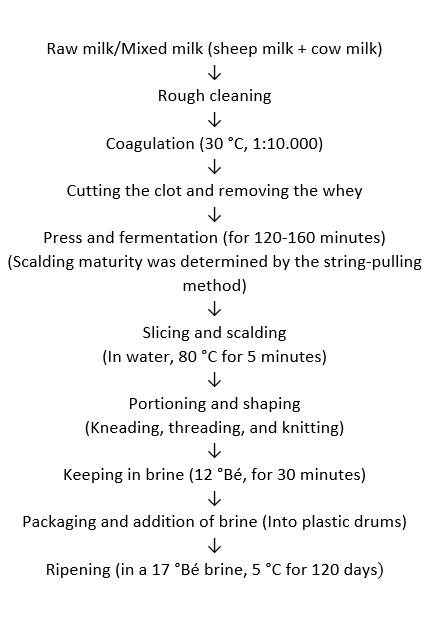

Diyarbakır Örgü Cheese (DOC) is one of the traditional cheeses produced in Türkiye (Hatipoğlu and Çelik, 2021a). DOC, which stands out with its traditional production method and unique flavour, has been certified with a protected denomination of origin (POD) since 2010 (Türk patent, 2022). It is mostly produced in the Karacadağ Basin region located in the south of the Diyarbakır province. The production process of DOC, a semi-fat and hard cheese, is similar to that of pasta-filata cheeses such as Mozzarella, Provolone, Queso Oaxaca, and Provola dei Nebrodi. To produce cheese, raw milk is coagulated with liquid rennet at 29-30 °C for 54-70 minutes. The obtained coagulum is then placed in the press cloth to be pressed and fermented. To test whether the curd is suitable for scalding, the string-pulling method is used. Fermented curd is placed into perforated stainless steel buckets, dipped into the boiler (78-87 °C water), and scalded for 2-7 minutes. The scalded curd is taken to the workbench, cut into portions of approximately 200 g, stretched in the form of a rope with a diameter of about 1.5-2 cm, and then braided like a typical hair braid. Fresh cheese is left in the brine (usually 12 °Bé) for about 20-30 minutes. Then, it is placed in a lacquered tin or plastic drums and filled with 17-21 °Bé brine, and subsequently ripened for about 4-6 months at 6±1 °C (Hatipoğlu and Çelik, 2020a).

Cheeses are generally evaluated for their composition, microbiological, textural, and organoleptic properties. The ripening process of cheeses has critical effects on these properties. During the ripening period, a series of microbiological and biochemical changes occur, including glycolysis, lipolysis, and proteolysis. Typical properties of cheese such as taste, aroma, and texture are formed by the effect of enzymes obtained from milk, rennet, starter and non-starter bacteria used during that period (van Mastrigt et al., 2018; Chen et al., 2020; Tudor Kalit et al., 2020).

Until now, a limited number of studies related to DOC have investigated its microbiological, biochemical, and textural properties (Hatipoğlu and Çelik, 2020a; Hatipoğlu and Çelik, 2020b; Hatipoğlu and Çelik, 2021a; Hatipoğlu and Çelik, 2021b; Canözer and Köse, 2022). In these studies, the level of dry matter, fat, fat in dry matter, protein, salt, salt in dry matter, ash, acidity (pH and °SH), soluble nitrogen in pH 4.6, soluble nitrogen in 12 % TCA, lipolysis and proteolysis, hardness, cohesiveness, springiness, adhesiveness, gumminess and chewiness, lactic acid bacteria, coliform, and fecal coliform group bacteria, Escherichia coli and yeast-mold of traditional DOC were investigated during the storage. Moreover, the antioxidant and antimicrobial activities and total phenolic compounds of the cheese were investigated.

In the presented research, some basic quality parameters of DOC produced using milk mixtures of different breeds were investigated during the maturation period. In other words, this study was carried out to determine the changes in volatile compounds, and textural and sensory properties during the maturation of DOC produced with cow and sheep milk or mixtures of these kinds of milk in different ratios.

Material and methods

The production of Diyarbakır Örgü cheese

DOC was produced by using milk of five different ratios (Table 1) during the routine cheese production season (March-June) in Karacadağ Basin, Diyarbakır, Türkiye (Figure 1). The produced DOC samples were taken into plastic drums (2 kg), which is the traditional packaging material, and stored for four months in cold conditions (5 °C) for ripening. The production of all cheese types was replicated twice. Also, all analyzes were performed on the 1st, 30th, 60th, and 120th days of the cheese storage period.

Table 1. Diyarbakır Örgü cheese samples and milk ratio used in their production

| Sample | Milk ratio |

|---|---|

| C1 | 100 % sheep |

| C2 | 100 % cow |

| C3 | 90 % sheep + 10% cow |

| C4 | 80 % sheep + 20% cow |

| C5 | 70 % sheep + 30% cow |

Figure 1. The production flow chart of traditional Diyarbakır Örgü cheese

Volatile organic compounds (VOC) analysis

VOC in the cheese samples was analysed by solid-phase micro-extraction (SPME) and gas chromatography-mass spectrometry (GC-MS) (Korkmaz et al., 2020). The SPME procedure was performed using an autosampler (AOC 5000 Plus, CTC, Switzerland). Two grams of grounded cheese were weighed in a 20 mL screw-capped bottle (Supelco, Bellefonte, PA, USA). A 5 µL of methanolic solutions of each of 2-methyl pentanoic acid (5 mg/L) (IS1) and 2-methyl-3-heptanone (5 mg/L) (IS2) were added as internal standards (IS). The sealed vial was equilibrated at 40 °C on the SPME unit of the autosampler for 30 min at an agitating speed of 300 rpm. Then, a fiber 50/30 μm DVB/CAR/PDMS (2 cm, Supelco, Bellefonte, PA) was injected into the vial and exposed to the headspace of the vial for 30 min at the same temperature and agitating speed. After that, the fiber was retracted from the vial and immediately inserted into the injector port of the GC-MS system for desorption at 250 °C for 5 minutes (with spitless mode). Analysis was made in triplicate for each sample.

The GC-MS system used was a Shimadzu GC-2010 Plus gas chromatography coupled with a Shimadzu QP2020 MS (Shimadzu Corp., Kyoto, Japan). Separation was achieved on a DB-Heavy WAX column (60 m x 0.25 mm x 0.25 µm film thickness) from Agilent. The temperature of the oven was set at 40 °C for 3 min followed by increasing to 80 °C at a rate of 3 °C/min, then raised to 240 °C with a rate of 5 °C/min and held this temperature for 6 min. Helium was used as the carrier gas at a flow of 1.07 mL/min. The mass detector was operated in a scanning range from 20 to 450 m/z and at EI mode (70 eV), with an ion source temperature of 201 °C.

VOC was identified based on their mass spectra matching with the standard Wiley 9 mass spectral library and on the comparison of their Retention Index (RI) with those of the NIST Standard Reference Database. The RIs were calculated by injecting a series of n-alkanes (C8-C26) (Sigma-Aldrich, USA) into the GC-MS under the same conditions. The quantification of VOC was done by multiplying the amount of IS by the peak area of each VOC to that of the IS and expressed as mg/kg. Volatile acids were quantified using IS1, while all others were quantified with IS2.

Texture profile analysis

Texture profile analysis (TPA) of the cheese samples was performed using Texture Analyzer (TA.XT Plus Stable Micro Systems Ltd., Surrey, UK) by modifying the method used by Hatipoğlu and Çelik (2020b). The cheese samples were sliced into 3 cm3 cubes. A 50 kg load cell with a 50 mm diameter stainless steel cylindrical probe (P/50, Stable Micro Systems Ltd., Surrey, UK) was used for TPA. Cheese samples with a height of 15 mm and a temperature of 25 °C were made in two dives with 80 % compression at a pre-test velocity of 10 mm/sec and a test velocity of 1 mm/sec.

The parameters of the textural properties (hardness, adhesiveness, springiness, cohesiveness, gumminess, and chewiness) of the samples were determined from the force-time graphs obtained using Exponent Stable Micro Systems software (UK, Version 6.1.16.0).

Sensory evaluation

The sensory evaluation of the cheese samples was carried out by 8 trained panelists aged between 30-45 from the Department of Nutrition and Dietetics, Mardin Artuklu University, Türkiye. A four-point hedonic scale was used for sensory evaluation. For colour appearance on the hedonic scale, one was scored as bad, two as adequate, three as good, and four as very good. For texture, one was evaluated as soft, two as normal, three as hard, and four as very hard. For taste-aroma intensity, one was mild, two was moderate, three was strong, and four was very strong (Awad, 2006).

Statistical analysis

The obtained data were analysed with a two-way ANOVA, and the difference between the significant averages was determined with the Duncan multiple comparison test (Watkins, 2021). In addition, principal component analysis (PCA) was applied to the data set of VOC to determine the similarities or differences between the cheese samples. All statistical analyses were performed using the SPSS program (Version 25.0, IBM).

Results and discussion

Changes in volatile aroma compounds

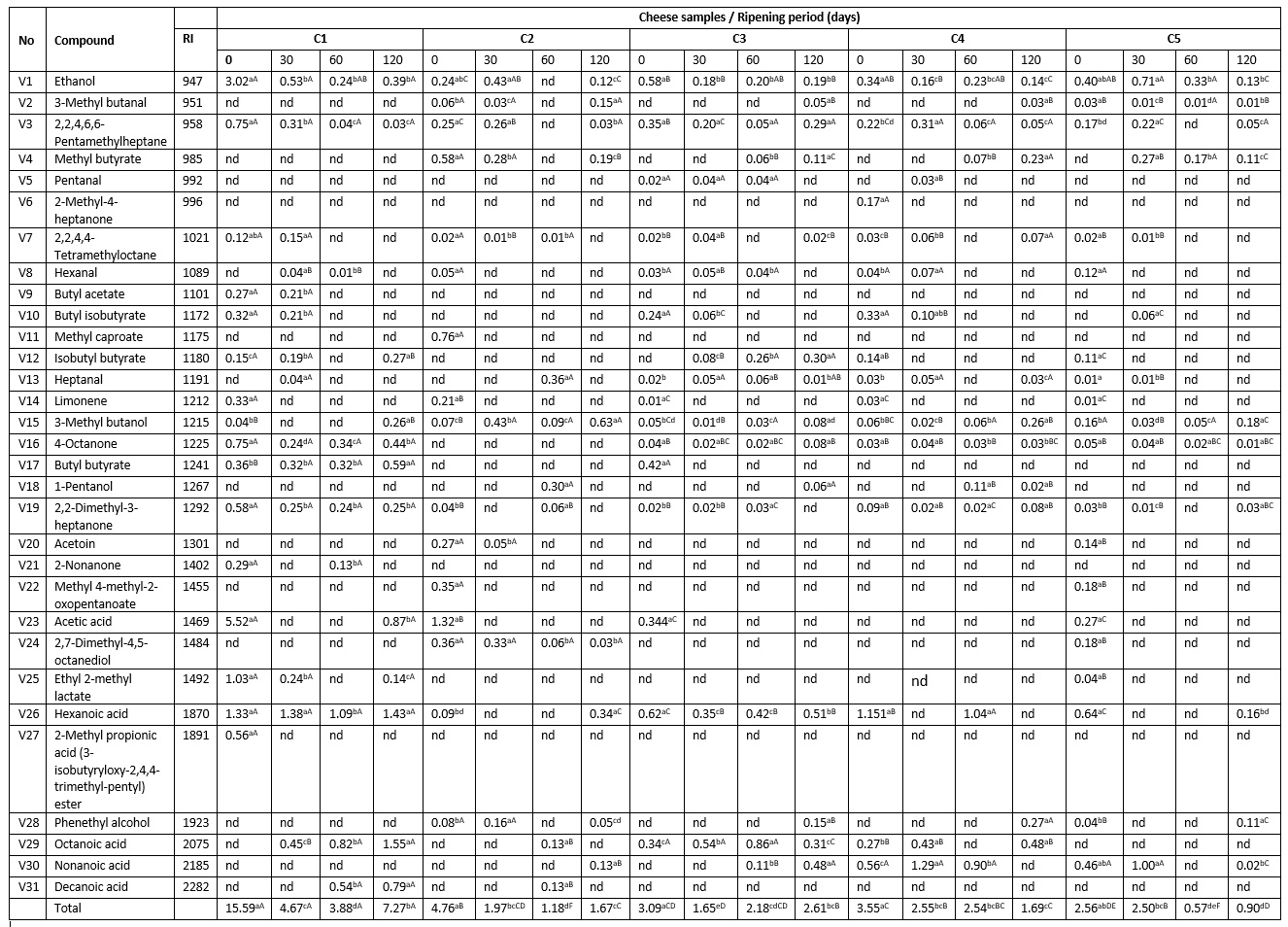

Volatile aroma compounds identified in the cheese samples are listed in Table 2 with their contents (mg/kg). A total of 33 compounds were identified and quantified in all cheese samples during the ripening. These were classified as follows: esters (10), alcohols (5), acids (5), ketones (5), aldehydes (4), and miscellaneous (4). The majority of these VOC were found in previous studies on various cheese types (Sözeri Atik et al., 2021; Zheng et al., 2021). The total VOC amount was highest in C2 group fresh cheese, while it was lowest in C5 group cheese at the end of 60-day ripening (Table 2). Some VOC of the samples disappeared during the ripening, whereas some new others were formed.

The VOC detected in the DOC samples was found to be qualitatively and quantitatively lower than those reported in other pasta-filata cheeses (Verzera et al., 2010; Sulejmani and Hayaloglu, 2016; Natrella et al., 2020; Sabia et al., 2020). This could be mainly due to a low level of lipolysis and proteolysis in DOC during the ripening (Celik and Turkoglu, 2007). The main sources of VOC in cheeses are free fatty acids and free amino acids formed as a result of lipolysis and proteolysis of various compounds derived from them (Sözeri Atik et al., 2021). Additionally, curd scalding and holding fresh cheese in a low salt brine (12 °Bé) during DOC production can cause further losses in amounts of free fatty acids, free amino acids, and lactose that turn into various classes of VOC during ripening (Delgado et al., 2011; Sözeri Atik et al., 2021).

In general, quantity and concentration of VOC in the sheep cheese were more than those in the cow cheese during the ripening (p<0.05). This difference can be explained by a higher content of short-chain free fatty acids in sheep milk, and also the higher level of lipolysis in the cheese sample produced from this milk (Boukria et al., 2020). Besides, the total VOC amount in all five cheese samples at the beginning of ripening decreased at the end of the 120-day ripening (p<0.05). Furthermore, the total VOC content of fresh sheep and cow cheese samples showed a decreasing trend until the first 60 days of the ripening and increased again in the next 60 days (p<0.05).

No increases in many VOC during the ripening of DOC can be explained by both its production method and ripening conditions. In this context, DOC is one of the scarce traditional cheeses in which a brine maturation following the heat treatment is used in its production. The scalding treatment mentioned above may cause the inactivation or reduced activity of microbial flora, rennet, and milk enzymes, which are responsible for lipolysis, proteolysis, and lactose fermentation (Atasoy and Türkoğlu, 2008; Tekin and Hayaloglu, 2023). Moreover, the ripening both in a high-salt brine and at a low temperature may also have reduced lipolytic and proteolytic activities to some degree (Azarnia et al., 1997; Türkoǧlu, 2011). Consequently, the biochemical changes that also provide the generations of new VOC in DOC during ripening occur to a limited extent (Hayaloglu and Karabulut, 2013). On the other hand, decreasing the amount of many VOC in DOC during ripening could be a result of their passing to the brine or/and their volatilization (Shahab Lavasani, 2021).

Esters were the most common group in all the cheese samples. The formation of esters not only contributes to a pleasant aroma (fruity) but also can reduce compounds in cheese that cause a rancid taste or off-flavour (Kendirci et al., 2020; Sözeri Atik et al., 2021). Ester compounds found in the samples can be formed between short-chain free fatty acids and alcohols by both direct (Bulat and Topcu, 2020) and enzymatic (Bas et al., 2019) esterification. Butyric acid esters of butanol and isopropanol were the most abundant in DOC samples. Methyl butyrate and methyl caproate as methyl esters were found only in cheeses made with cow's milk, while butyl esters of butanoic acid were found in higher amounts in cheeses made with sheep's milk (p<0.05).

Among volatile acids, hexanoic and octanoic acids were the most abundant in the cheese samples. The amounts of these compounds in the samples obtained from sheep's milk were higher than those obtained from cow's milk (p<0.05) as reported by Boukria et al. (2020). Acetic acid was present in the cheese samples at beginning of ripening, except for the C4, but disappeared in the later stages of the ripening. In particular, this acid was found to be predominantly higher in the cheese samples made with only sheep's milk (p<0.05). It could be produced by lactose fermentation (Bulat and Topcu, 2020) volatile compounds, and sensorial properties of experimental ultrafiltered (UF). As a remarkable result, butyric acid with the typical cheese aroma was not found in all samples, probably due to its complete conversion to esters.

Table 2. Changes in volatile aroma compounds (mg/kg) in Diyarbakır Örgü cheese produced from different types of milk during the ripening period

C1: 100 % sheep milk cheese; C2: 100 % cow milk cheese; C3: 90 % sheep milk + 10 % cow milk cheese; C4: 80 % sheep milk + 20 % cow milk cheese; C5: 70 % sheep milk + 30 % cow milk cheese; v: volatile compounds; nd: Not detected; RI: Retention Index calculated on DB-HeavyWax column

a-e Means with different letters in the same row are significantly different between ripening times in the same sample (p<0.05).

A-F Means with different letters in the same row are significantly different between the same ripening times in different samples (p<0.05)

Regarding alcohols, it can be seen that ethanol and 3-methyl butanol were detected in almost all cheese samples during ripening. Ethanol in the samples showed a decreasing trend during ripening, but the latter exhibited an increasing trend (p<0.05). 3-Methyl butanol, which gives a desirable aroma to cheeses, may be derived from isoleucine, while ethanol could be produced by lactic acid bacteria from lactose (Engels et al., 1997). Phenethyl alcohol (floral-like) was detected only in the cheeses containing cow's milk. This compound can be derived from phenylalanine (Roger et al., 1988).

Ketones with low odor thresholds are significant compounds that either enhance or adversely affect the flavour of cheeses, depending on which compound is present in them (Teter et al., 2020). Acetoin (3-hydroxy-2-butanone) (buttery) was detected in fresh and 30-day-old mature cow cheese samples. In addition, acetoin was found in fresh C5 group cheeses, one of the cheeses produced from mixed milk. However, it was lost completely in these samples at the end of the ripening. The ketones with the highest concentration in the cheese samples were 4-octanone (pine-like) and 2,2-dimethyl-3-heptanone. On the other hand, 2-nonanone (cheesy) was detected only in cheese made from sheep's milk. Acetoin in cheese can be produced through the catabolism of alanine, while the other ketones were probably formed by the β-oxidation of free fatty acids (Bas et al., 2019).

As aldehydes, hexanal (green-like), heptanal (green-like), pentanal (fermented-like), and 3-methyl butanal (fruity) were detected at different stages of ripening in the samples. The first three as the straight-chain aldehydes in cheese can be produced by β-oxidation of fatty acids, whereas 3-methyl butanal as a branched aldehyde may be generated by amino acid metabolism (Engels et al., 1997). Limonene (citrus-like) was the only terpenoid compound found in cheeses, likely arising from animal feeds (Atasoy et al., 2013).

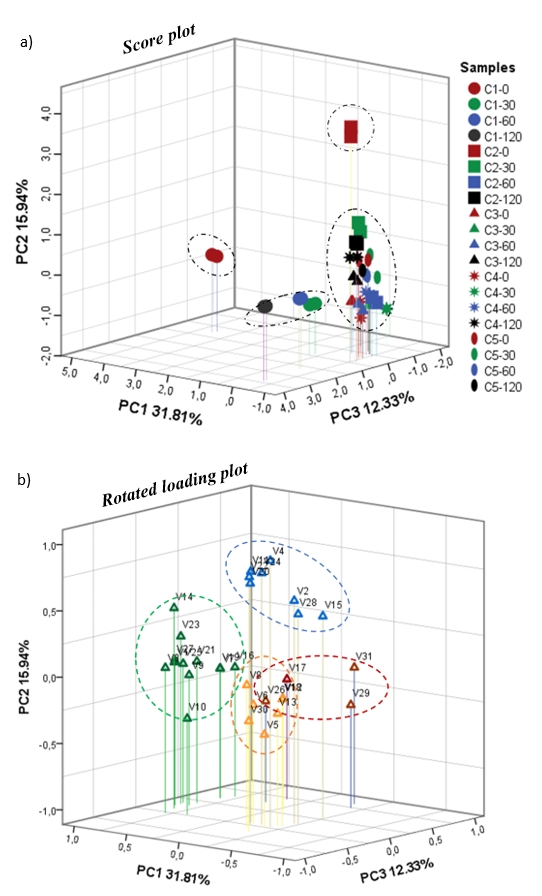

Principle component analysis

The result of PCA obtained from VOC data in DOC samples is shown in Figure 2. Three principal components (PCs) explained 60.08 % of the total variance of the data set. The first (PC1), second (PC2), and third (PC3) principal components accounted for 31.81, 15.94, and 12.33 % of the variance, respectively. As can be seen in the score plot (Figure 2a), the fresh sheep cheese was separated from all others by PC1. Likewise, the fresh cow cheese was also differentiated from others along PC2. The samples of sheep milk cheese during ripening were partially separated by PC3. The rest of the samples were clustered on the same region of the score plot. Although all samples were clustered in four groups according to the assessment of PCA on the data set, the relatively lower the total variance from the first three PCs indicates that there were no sharp differences between the compositions of their VOC. Furthermore, only the first three PCs are insufficient for the explanation of the total variance in the data set of VOC (Eroglu et al., 2015).

The loadings of the VOC on the first three PC are illustrated in Figure 2b, which represents the contribution of each VOC to the similarities or differences between the samples. The most discriminative VOC in the fresh cheese produced sheep milk were acetic acid, butyl acetate, ethanol, 2-nonanone, ethyl 2-methyl lactate, 2-methyl propionic acid (3-isobutyryloxy-2,4,4-trimethyl-pentyl) ester. Compounds acetoin, methyl caproate, methyl 4-methyl-2-oxopentanoate and 2,7-dimethyl-4,5-octanediol were responsible for the characterization of the VOC profile in the fresh cow cheese. For the sample of sheep cheese during ripening, decanoic, octanoic, and hexanoic acids, and butyl butyrate were associated with the discrimination of its aroma. Papademas and Robinson (2000) have also reported that Hellim cheese, which is similar to DOC as one of the curd-scalded and brined cheeses, from sheep milk had higher amounts of volatile fatty acids during ripening compared to those made with cow milk. Hayaloglu and Karabulut (2013) have previously compared the profile of VOC in 11 different traditional Turkish cheeses using PCA. They found that the scalded and brined varieties such as Dil, Hellim, Malatya, Orgu, and Urfa cheeses were clustered in the same group, and had lower contents for all VOC.

Figure 2. Score plot (a) and loading plot (b) of the three first components of PCA for Diyarbakır Örgü cheese produced from different types of milk during the ripening period. Abbreviations; v: volatile compounds numbered from 1 to 31 in Table 2; 0-120: Ripening days from 0 to 120; C1:100 % sheep milk cheese; C2: 100 % cow milk cheese; C3: 90 % sheep milk + 10 % cow milk cheese; C4: 80 % sheep milk +20 % cow milk cheese; C5: 70 % sheep milk + 30 % cow milk cheese.

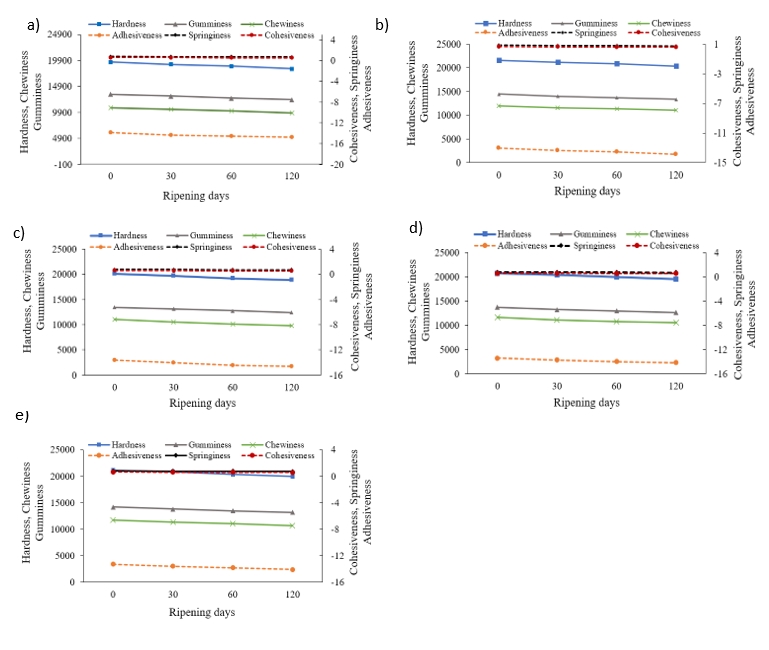

Texture profile

The hardness in all DOC samples decreased during the storage period (Figure 3) (p<0.05). The highest hardness was determined in the C3 group fresh cheese samples, and the lowest in the C1 group mature (120th day) cheese samples. In addition, it was observed that the hardness level increased as the amount of cow's milk in the mixture increased.

C1: 100 % sheep milk cheese; C2: 100 % cow milk cheese; C3: 90 % sheep milk + 10% cow milk cheese; C4: 80 % sheep milk + 20 % cow milk cheese; C5: 70 % sheep milk + 30 % cow milk cheese.

Figure 3. Changes in the texture of C1 (a), C2 (b), C3 (c), C4 (d) and C5 (e) samples during the ripening period

It was reported by different researchers that short and medium-chain fatty acids and polyunsaturated fatty acids were higher in sheep's milk cheeses than in cow's milk cheeses (Paszczyk and Łuczynska, 2020; Ochoa-Flores et al., 2021). On the other hand, it was stated that the hardness of Kashar cheese, which is a pasta-filata type cheese, decreased with the decrease in fat content (Koca and Metin, 2004). Due to the issues mentioned above, it can be said that cheeses with increased cow's milk are harder than those made from sheep's milk. Also, the level of proteolysis and lipolysis that occurs during ripening, as well as the moisture content affect the hardness of the cheese negatively (Lobato-Calleros et al., 1998; Prasad and Alvarez, 1999; Młynek et al., 2018). The increase in lipolysis and proteolysis during the storage hydrolyzes fat and protein and softens the cheese matrix. In addition, the decrease in Ca, attributed to Ca ion diffusion in the brine solution, causes a decrease in colloidal Ca, which increases the softening of the cheese. (Ayyash et al., 2011; Młynek et al., 2018).

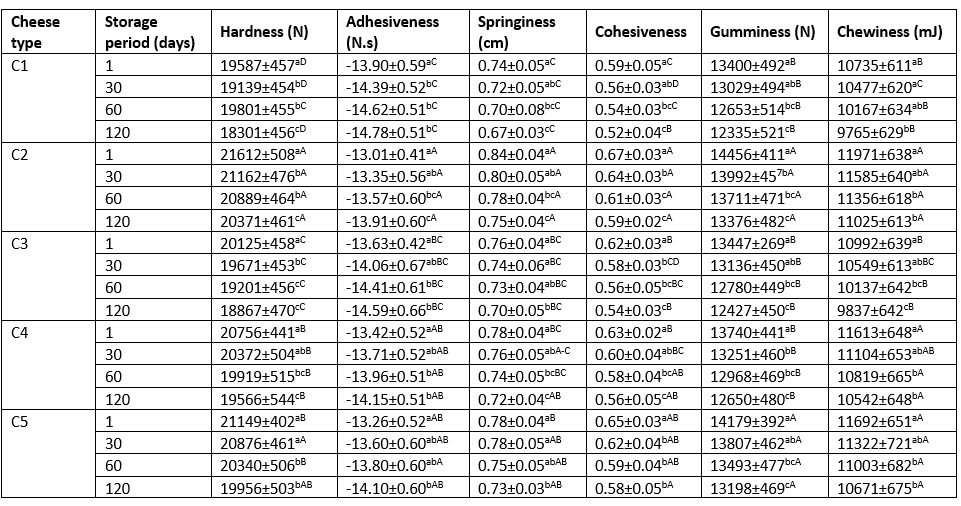

Table 3. Changes in texture parameters of the Diyarbakır Örgü cheese samples produced from different kinds of milk during the ripening period

C1: 100 % sheep milk cheese; C2: 100 % cow milk cheese; C3: 90 % sheep milk + 10 % cow milk cheese; C4: 80 % sheep milk + 20 % cow milk cheese; C5: 70 % sheep milk + 30 % cow milk cheese.

a-c Means with different letters in the same column are significantly different between ripening time in the same sample (p<0.05).

A-D: Means with different letters in the same column are significantly different between the same ripening times in different samples (p<0.05).

Moreover, the degradation products formed as a result of proteolysis and lipolysis bind the water in the environment more, causing the cheese to soften (Hatipoğlu and Çelik, 2020b; Zonoubi and Goli, 2020). Besides, monovalent salts (sodium) with a higher ability to reduce electrostatic repulsions facilitate interparticle interactions by creating a charge balance between protein particles in the early phase of the cheese storage period (in the first weeks). Due to the strong interactions and polymerization of the network chains, a structure with high molecular density and strength were obtained (Zonoubi and Goli, 2020). In other words, on the first day of storage, the hardness was at the highest level, since the interaction between the particles was the highest in the presence of salt (Table 3).

It is known that adhesiveness is related to the proteolysis level, acidity, polar characteristics of lipids, and protein fractions of cheese (Bryant et al., 1995; Romani et al., 2002). Since the lipolysis level in cheese made from sheep's milk is higher than in cow's milk cheeses, the short, medium, and long-chain fatty acids formed in these cheeses are higher (Boukria et al., 2020). In the mature cheeses, it was stated that the decrease in fat content as a result of lipolysis (Yates and Drake, 2007) and the hydrophobic groups formed as a result of proteolysis lead to an increase in the hydrophobic interactions between the particles, resulting in a decrease in adhesiveness in cheese (Zonoubi and Goli, 2020). According to the ANOVA calculations, the difference between the mean adhesiveness values of all the cheese types was statistically significant (p<0.05) during the storage period. The highest adhesiveness was observed in C2 group mature (120th day) cheeses. On the other hand, with the maturation of the cheeses, a decrease was observed in the adhesiveness values (Table 3). The decrease in adhesiveness with the maturation of cheese was similarly reported in the study of Tomar (2019) for Tulum cheese.

Differences were observed between the springiness values of DOC types (p<0.05) (Table 3). As can be seen in Table 3, the C2 group DOC samples have the highest springiness value during the ripening. Moreover, it was determined that the springiness of the cheeses decreased during the storage period. It was reported that fresh cheeses were more elastic than mature ones because they contain more fat and less moisture (Fresno and Alvarez, 2012; Oluk et al., 2014). Kędzierska-Matysek et al. (2013) reported, as well, that the springiness of the cheeses produced from sheep's milk was higher than those produced from cow's milk.

As the amount of cow's milk in the mixture increases, there was a continuous increase in the cohesiveness values of the cheeses (Table 3). Kędzierska-Matysek et al. (2013) reported that Oscypek cheese produced from sheep's milk had three times more binder than Gazdowski cheese produced from cow's milk. The difference between the mean cohesiveness of cheese types during the storage period was significant (p<0.05). The highest cohesiveness was observed in the C2 group fresh cheese samples, while the lowest was observed in the C1 group mature (120th day) cheese samples. It was stated that the binding in cheese decreases due to the degradation of the casein network structure (proteolysis) and the increase in lipolysis levels during ripening (Yates and Drake 2007; Delgado et al., 2011).

The difference between the gumminess averages of all DOC samples in the study was significant at the p<0.05 level (Table 3). The lowest gumminess value was determined in the C1 group cheese samples. This value increased as the cow's milk mixture ratio increased and reached the highest level in C2 group DOC samples. In addition, a decrease was observed in the gumminess of DOC samples with maturation. On the contrary, it was reported that the gumminess increased with ripening in Cheddar (Voigt et al., 2012).

Since the chewiness value of cheeses is the result of the multiplication of the gumminess and springiness values (Katsiari et al., 2002), it is expected that all factors affecting the gumminess and springiness parameters will also affect the chewiness. It was observed that the difference between the chewiness averages of all DOC samples during the storage period was significant at the p<0.05 level (Table 3). As the amount of cow's milk in the mixture increased, the chewiness level of the cheeses increased. It was reported that as the fat content of cheese decreased, the chewiness increased, while the chewiness decreased with the increase in moisture and fat ratios (Zheng et al., 2016). On the other hand, DOC matured in brine softens with the increase in moisture content (Hatipoğlu and Çelik, 2020a). Therefore, the lowest chewiness was observed in the mature C1 group DOC, and the highest chewiness was observed in fresh C2 group samples (Table 3). It was documented that the level of chewiness decreased with maturation in DOC (Hatipoğlu and Çelik, 2020b) and Ras (Awad, 2006) cheeses. Further, it was reported that these values fluctuate throughout the ripening period in Ibores cheese (Delgado et al., 2011).

Sensory properties

One of the specific characteristics of cheeses that are critically important for consumer acceptance is flavour (taste-aroma). Flavour directly affects the acceptance or rejection of cheeses (Bezerra et al., 2017). Flavour originates from the quantitative and qualitative contents of volatile compounds that vary depending on the type of cheese (Atasoy et al., 2013). The objective determination of the quality of cheeses is mostly done by sensory evaluations using trained panelists. Thus, aspects of cheeses that are appreciated and/or seen as defective by consumers can be designated (Walsh et al., 2020).

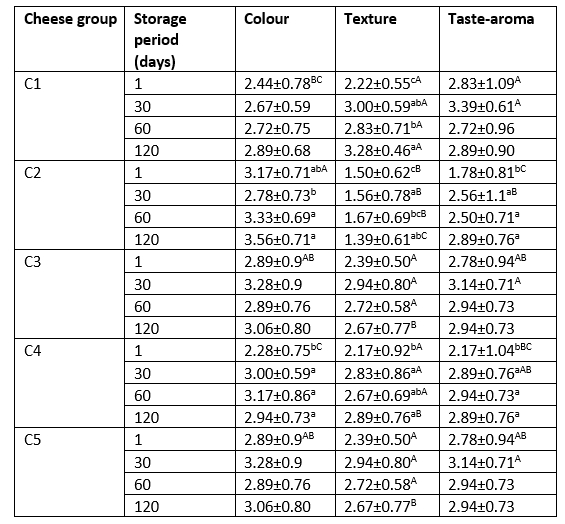

According to the variance analysis results, although there was a significant difference (p<0.05) between the sensory colour averages of fresh DOC samples, no difference was observed between the other cheeses (p>0.05). When the sensory colour scores of the cheese samples were examined, the highest score was obtained from mature (120th day) C3 group DOC samples, and the lowest score was obtained from C4 group fresh DOC samples (Table 4). When evaluated in general, the colours of C3 group cheeses were preferred more, while the colours of C1 group cheeses were the least liked.

Table 4. Changes in sensory properties of the Diyarbakır Örgü cheese samples produced different types of milk during the ripening period

C1: 100 % sheep milk cheese; C2: 100 % cow milk cheese; C3: 90 % sheep milk + 10 % cow milk cheese; C4: 80 % sheep milk + 20 % cow milk cheese; C5: 70 % sheep milk + 30 % cow milk cheese.

a-c Means with different letters in the same column are significantly different between ripening time in the same sample (p<0.05).

A-D: Means with different letters in the same column are significantly different between the same ripening times in different samples (p<0.05).

The sensory properties of cheese depend on many factors such as the type of milk, the composition of the raw material, and the production technology (Filipczak-Fiutak et al., 2021). In this context, mostly sheep's milk is white in colour, and cow's milk is closer to yellow, depending on the animal's feed. This is also reflected in the cheeses produced. Accordingly, the panelists participating in the study more preferred cheeses with intense yellow colour.

In terms of sensory texture, mature (120th day) C1 group DOC samples were the most liked, and mature (120th day) C3 group DOC samples were least liked. When evaluated in terms of taste and aroma, the most liked were 30 days C1 group DOC samples, and the least liked were fresh C3 group DOC samples. It is also known that DOC absorbs more salt with maturation in brine (Hatipoğlu and Çelik, 2020a). Therefore, panelists stated that mature cheeses were saltier and gave lower scores than fresh cheeses. Moreover, when considered in terms of both sensory texture and taste-aroma, as the amount of cow's milk added to the mixed milk increased, there was a tendency to decrease the level of taste-aroma (Table 4).

While there are studies similar to the results of this research, there are also studies with different results. In this context, it was reported that Manchego cheeses produced from sheep milk got higher scores in terms of taste, aroma, and texture compared to those produced from cow's milk (Ochoa-Flores et al., 2021). On the contrary, it was documented that cheeses produced from cow's milk were more preferred in terms of the same parameters (Filipczak-Fiutak et al., 2021).

Conclusion

Reducing the ratio of sheep's milk in the production strengthened the textural properties of the cheese, but these properties were weakened by the prolongation of the storage period. The sensory texture score increased during the storage period of the cheese. As the cow's milk ratio increased, the scores given to the sensory texture of the cheese gradually decreased. Since salt diffused from brine to cheese with maturation, mature cheeses were saltier and therefore less preferred.

The results of the VOC analysis showed that both the amount and the numbers in DOC produced from sheep, cow and their mixed milks in different proportions were lower than many traditional cheese varieties. Nevertheless, the findings indicated that the most abundant VOC group in DOC during ripening was short-chain fatty acid esters. The results of PCA revealed that the VOC composition in DOC made from sheep milk at the beginning of the ripening period differed from that of cow milk, also that cow milk cheese and mixed milk cheeses got closer to each other in terms of their profile of VOC at the end of storage. However, the sheep DOC cheese was separated from all other samples due to its higher volatile fatty acid content during ripening.

As a conclusion, it can be said that the production method and storage conditions of DOC as well as the kind of milk used, have an effect on the characteristic features of DOC. The cheese produced from sheep's milk is preferred by consumers, but since this cheese variety is relatively soft, it was concluded that 10 % of cow's milk can be used in cheese production as a result of this study. Individuals who demand mature cheese are recommended to consume it after 30 days of the ripening period, due to the increase in VOC concentration in mature cheese. Future studies should focus on the amino acid and fatty acid profiles in DOC because of their significant contribution to the taste-aroma profile.

Funding

This study was supported by Scientific Research Projects Coordinatorship of Mardin Artuklu University (MUBAP, Project No: MÜ-BAP-20-SBF-002).

Hlapljivi profil, teksturalna i senzorska svojstva Diyarbakır Örgü sira proizvedenog od ovčjeg i kravljeg mlijeka različitog vremena zrenja

Sažetak

Diyarbakır Örgü (pleteni) sir (DOS) je polumasni, tvrdi sir tipa pasta-filata. Cilj ove studije bio je procijeniti hlapljive arome, prihvatljivost kod potrošača i svojstva teksture DOS tijekom 120-dnevnog razdoblja sazrijevanja. U tu svrhu proizvedeno je ukupno 5 različitih DOS od 100 % ovčjeg mlijeka (C1), 100 % kravljeg mlijeka (C2), 90 % ovčjeg mlijeka + 10 % kravljeg mlijeka (C3), 80 % ovčjeg mlijeka + 20 % kravljeg mlijeka (C4) i 70 % ovčjeg mlijeka + 30 % kravljeg mlijeka (C5). Tijekom zrenja identificiran je ukupno 31 spoj, uključujući estere (9), alkohole (5), kiseline (5), ketone (5), aldehide (4) i ostale (3) u svim uzorcima sireva. Kako se postotak ovčjeg mlijeka koji se koristi u proizvodnji sira povećavao, hlapljivi spojevi su se povećavali i kvalitativno i kvantitativno. Na početku zrenja ukupna količina HOS-a u DOS-u proizvedenom od ovčjeg mlijeka bila je 3,27 puta veća nego u proizvedenom od kravljeg mlijeka, dok se taj omjer na kraju zrenja povećao na 4,57. Ukupni sadržaj HOS-a svih DOC-a smanjio se tijekom zrenja za 53,37, 64,92, 15,53, 51,81 i 64,84 % za C1, C2, C3, C4 i C5, redom. Povećanje količine ovčjeg mlijeka koje se koristi u proizvodnji i vremena zrenja uzrokovali su povećanje hlapljivih organskih spojeva u siru, kako u pogledu broja tako i u koncentraciji (p<0,05). Kako se povećavala količina kravljeg mlijeka koje se koristi u proizvodnji sira, općenito su rasle vrijednosti svih teksturalnih svojstava. S druge strane, te su se vrijednosti smanjivale sazrijevanjem (p<0,05). Stope smanjenja vrijednosti tvrdoće, adhezivnosti, elastičnosti, kohezivnosti, gumenosti i žvakanja skupina sireva nakon skladištenja bile su C1>C3>C2>C4>C5, C4>C1>C5>C2>C3, C2>C1>C3>C4>C5, C3>C2>C1>C5>C4, C1>C4>C3>C2>C5 i C3>C4>C1>C5>C2. Što se tiče senzorske boje, teksture i okusa - arome, više su preferirani uzorci sira skupine zreli C2, zreli C1 i 30 dana zreli C1.

Ključne riječi: Diyarbakır Örgü sir; pasta-filata; senzorska svojstva; profil teksture, hlapljivi organski spojevi

References

Lobato-Calleros, C., Vernon-Carter, E.J., Hornelas-Uribe, Y. (1998): Microstructure and texture of cheese analogs containing different types of fat. Journal of Texture Studies 29 (5), 569-586.

https://doi.org/10.1106/108201302028118

van Mastrigt, O., Tejeda, D.G., Kristensen, M.N., Abee, T., Smid, E.J. (2018): Aroma formation during cheese ripening is best resembled by Lactococcus lactis retentostat cultures. Microbial Cell Factories 17, 104.