Introduction

High-quality goat milk is produced from clean, healthy, and properly managed goat herds, and is essential for the production and marketing of high-quality dairy goat products (Park, 2011). Goat milk has long been associated to certain health benefits, particularly due to its high content of short- and medium-chain fatty acids, but this remains little known and little utilized (Turkmen, 2017). However, consumers' awareness of production values has increased, and goat milk, cheese and whey are growing in popularity. Numerous factors influence the quality of goat milk. Different European regions and production systems produce goat milk with different compositions, and hygienic and microbiological quality (Morgan et al., 2003). The goat breed has a strong influence on milk quality, goat cheese quality and especially cheese yield (Herrera et al., 2010; Laučienė et al., 2022). In addition, breed was the most influential source of variation for almost all cheese traits (Vacca et al., 2018). Research by Inglingstad et al. (2014) found that milk composition was affected by both, feeding and season. For example, milk from pasture-fed goats had higher protein and casein content than milk from hay-fed goats. The quality and composition of raw milk are among the most important factors determining cheese yield and quality (Fekadu et al., 2005). The higher fat and protein content of the milk contributed to the higher cheese yield as well as to the efficiency of the nutrients utilized in the curd (Pazzola et al., 2018).

Excessive nitrogen in the ration increases the nitrogen content in the milk and decreases its quality for cheese making. The effect of goat rations on the composition of milk with high and low nitrogen content showed that higher nitrogen content contributes to the production of more milk but less milk fat. The content of urea, dry matter, fat, NaCl and citrate in milk varied depending on the meal, indicating the dependence of milk composition on the structure of the meal (Lefrileux et al., 2012). It was also found that the content of urea and milk urea nitrogen (MUN) in goat milk is positively correlated with the concentration of crude protein (CP) in the feed (Bonanno et al., 2008).

The production of cheese of a particular composition, yield and quality from a particular goat milk source is of significant economic interest to producers, manufacturers and consumers (Fekadu et al., 2005). Using diet as a predictor of fatty acid composition Kourimaska et al. (2014) confirmed the feasibility of modelling goat milk. Specifically, goat milk grazed on pasture had higher levels of short-chain saturated fatty acids, DHA, EPA, and total polyunsaturated fatty acids. The amount of n-6 fatty acids decreased and the n-6/n-3 ratio was lower compared to goat milk obtained from goats fed hay and concentrate. In addition, Yakan et al. (2019) found that milk from goats raised on pasture had lower values for saturated fatty acids, atherogenic index, thrombogenic index, and odour index compared to goats fed concentrate. It was also found that goats kept on pasture produced milk with a more favourable fatty acid profile in early lactation compared to the late lactation period. Milk and cheese health indices are useful tools to determine the presence of health-promoting compounds and, in turn, the general health value of the product (Giorgio et al., 2019). The authors also found significant differences in the fatty acid profile and polyphenol content of cheeses made from the milk of goats grazing on grasses and legumes, which are common in the Mediterranean region. Furthermore, the partial replacement of soybean meal with extruded linseed-enriched goat milk increased ALA and total n-3 fatty acids, while the replacement of soybean meal with pumpkin seed cake reduced linoleic acid in milk (Klir Šalavardić et al., 2021).

The production of goat milk and dairy products is still underdeveloped in Serbia. Goat cheese is still mainly produced at the household level or in small dairies (Paskaš et al., 2020). As a result, industrial production of white goat cheese is not sufficiently developed in Serbia (Barać et al., 2013). According to a survey of consumer attitudes in Vojvodina, goat cheeses are less acceptable to consumers than cheeses made from cow milk. However, they are more desirable than other goat milk products (Paskaš et al., 2020a). White cheese is one of the most consumed cheeses in Serbia (Paskaš et al., 2020a). It is usually produced from raw or thermally treated cow's or sheep's milk, and less frequently from goat's milk (Barać et al., 2013).

This study investigated whether different feeds and production methods affect goat milk quality and its suitability for white-brined cheese production. In addition, the nutritional indices and the fatty acid profile of goat's milk and white cheese were evaluated as well as the sensory characteristics of the cheese and the whey quality.

Material and methods

Milk sampling and physicochemical analysis

The experiment was conducted from the end of April to the middle of May 2022. Samples were collected from two local dairy farms of the same size (250 lactating goats) but with different production systems (pasture and indoor). French Alpine was the main breed on both farms. On each farm, bulk milk was collected once a week for 3 weeks (at regular intervals) and analysed on the same day. Goats were mechanically milked twice a day and samples were taken in the morning. Standard chemical composition and urea content (MU) of milk samples was performed using a MilkoScan FT+analyzer for routine Fourier Transform Infrared "FTIR" compositional analysis of raw milk. The techniques of the MilkoScanTM FT+ comply with the standard: ISO 9622/IDF 141:2020 and the official AOAC method 972.16. The energy value of milk was estimated according to Serbian regulations (2014). Milk urea nitrogen (MUN) was obtained by multiplying the value of MU by a conversion factor of 0.4665 (Bonnano et al., 2008). FossomaticFT FC (ISO 13366-2:2008) and BactoScanTM FC+ (ISO 16297:2020) were used to determine the somatic cell count and total bacterial count of raw milk. The pH of the milk was measured using a pH meter (WTW, type ino Lab pH 720) (AOAC 981.12) .

Cheesemaking

The white goat brined cheese was produced according to traditional methods from batches of 5 litres of milk. A total of 6 batches of white brine cheese were produced (3 from each farm). The milk was gradually heated to 63-65 °C for 30 minutes. The milk was then cooled to 34 °C. In the next step, CaCl 2 was added in the form of a water solution in an amount of 0.02 %. No starter cultures were added. After standing for five minutes, 5 mL of liquid rennet (MTM Sirela, Čačak, Serbia, 85 % chymosin and 15 % pepsin; 1:5000) was added. Coagulation took place for 60-75 minutes, at 32-33 °C. When the curd became firm, it was cut into cubes (size 8-10 cm). It was left to stand for 10 minutes and then gently stirred for a further 5-10 minutes. The curd was then placed in the cheesecloths and the mixture was slowly drained and pressed by itself over the next few hours at a temperature of 15-20 °C. When the curd reached the right consistency, it was cut into slices (10x10x3cm) and dry salted (3-4 %, of the cheese mass). The next day cheese was placed in brine (6 % NaCl solution) and sealed in plastic boxes. The ripening in the brine lasts for 21 days during which the cheese remains constantly submerged.

Physicochemical analysis of cheese and whey

The cheeses produced were weighed immediately after production, using a digital weight balance (Sartorius, TE2145). A total of 6 cheese and 6 whey samples were analyzed. Dry matter was determined using a standard method for measuring weight loss after drying (AOAC 926.08-1927). For protein content, the Kjeldahl-Van Slyke method for determining total N (AOAC 2001.14) was used with a Kjeltec Auto Analyzer and conversion with a multiplication factor of 6.38. Fat content was determined according to IDF (2008) and ash was determined by dry ashing at 550 °C (AOAC 935.42). The total salt content was determined by the Volhard method (AOAC 935.43). The pH value of cheese and whey was measured using a pH meter (Consort, Turnhout, Belgium) (AOAC 920.124). The energy value was determined according to the Serbian regulations (2014). The formula of Vacca et al. (2018) was used to calculate the theoretical and actual yields of cheese, total solids and water, as well as the efficiency of cheese production and the utilization of total solids, fat and protein. The formula of Popović-Vranješ and Vujičić (1997) was used to determine the percentage of whey in milk.

Fatty acids profile and nutritional indices

Milk and white-brined cheese fat were extracted and esterified according to AOAC (2005) 996.06. Determination of fatty acids was performed after methylation with boron trifluoride in methanol, using a Shimadzu gas chromatograph with flame ionization detector (FID) on an Intercap column WAX (length 30 m, inner diameter 0.25 mm, film thickness 0.25 µm). Health-promoting index (HPI), linoleic acid/α-linolenic acid ratio (LA/ALA) and hypocholesterolemic/hypercholesterolemic ratio (HH), were determined according to Chen and Liu (2020). The atherogenicity index (AI) and thrombogenicity index (TI) were calculated according to Ulbricht and Southgate (1991).

Sensory analysis

Sensory analysis was performed after 3, 14 and 21 days of ripening. A sensory panel (n=8) evaluated the cheese samples according to the quality evaluation method (ISO 22935-2:2009). The experimental cheeses were evaluated according to the following characteristics: appearance, colour, texture, cross-section, odour and flavour. Each characteristic was individually scored on a 5-point scale (1 = poor to 5 = excellent). The maximum points that could be awarded on a 5-point scale were as follows: colour-1, appearance-2, odour-2, cross-section-3, and flavour 10 points. The scores were multiplied and the total score for excellent cheese was 100. Samples were randomly presented and scored individually.

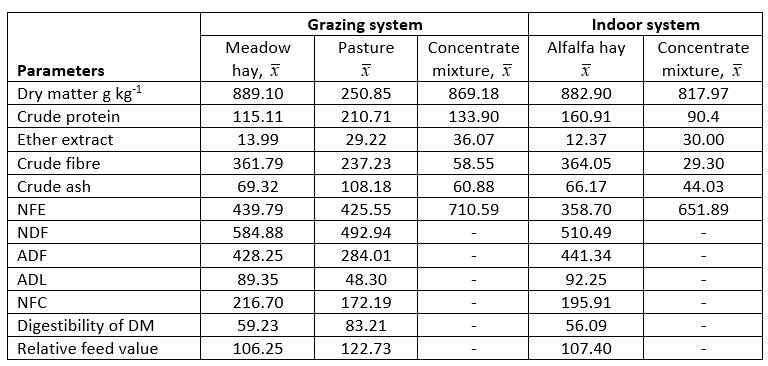

Feedstuff composition and goat's diet

The goats received adequate hay, and water was offered ad libitum. At milking time, a concentrate mixture was given twice daily (600 g/day/goat). Pasture forage was provided for the goats on the first farm. Three analyses were performed for each feedstuff. The nutritional composition of the goat feed is shown in Table 1.

Table 1. Nutrient composition of feedstuffs (g kg -1 DM)

NFE - nitrogen-free extract; NDF - neutral detergent fibre; ADF - acid detergent fibre; ADL - acid detergent lignin; NFC - non-fibre carbohydrates; x - arithmetic mean

Statistical analysis

The obtained results were statistically analysed and presented as arithmetic mean, standard deviation, range and coefficient of variation. A significant difference between the means was determined using the t-test procedure at p<0.05. The parameters of sensory properties were unilaterally studied at ANOVA followed by Tukey`s multiple comparison test. Statistical analysis was performed using Statistica 10 ( StatSoft STATISTICA 10.0).

Results and discussion

Milk physicochemical composition

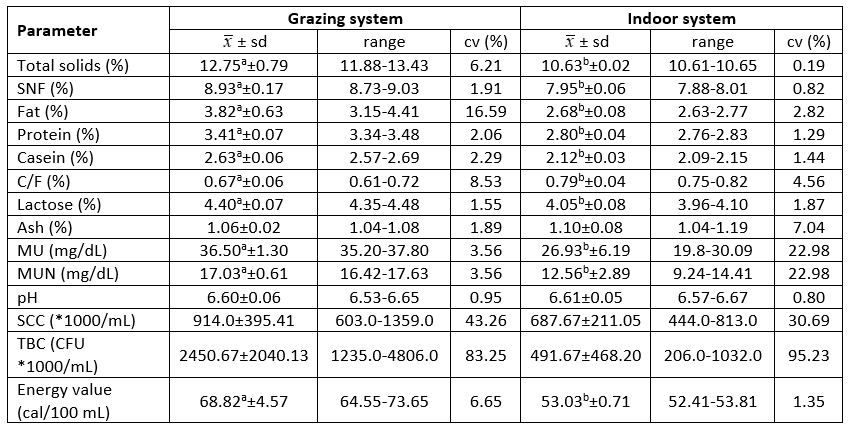

The physicochemical composition of goat milk is presented in Table 2.

Table 2. Physicochemical composition of goat milk

SNF - solids non-fat; C/F - casein/fat; SCC - somatic cells count; TBC - total bacteria count; x ±sd - arithmetic mean ± standard deviation; cv - coefficient of variation; Means with different letters are significantly different (p<0.05).

Higher levels of total solids, fat, protein, lactose and casein were found in the milk of goats fed on pasture. The differences in milk fat content (3.96 vs. 2.68 %) were particularly striking. Similar results were also reported by Inglingstad et al. (2014), Rolinec et al. (2018) and Bodnár et al. (2021). Nayik et al. (2021) emphasized that consumption of grass in the first growth phase had a positive effect on goat milk production and fat content. Similarly, Inglingstad et al. (2014) pointed out the benefits of pasture-based husbandry for milk fat production. In contrast to chemical composition, there was no statistically significant difference between milk pH values (p<0.05). Casein to fat ratio is of great importance in cheese production as it influences the compositional structure and cheese yield, but is not widely standardised in traditional cheese production (Hayaloglu et al., 2008). In general, milk with a lower C/F ratio is preferred for soft cheeses while milk with a higher C/F ratio is preferred for hard cheeses (Ehlers and Hurt, 2015). The casein-to-fat ratio for white brine cheeses is between 0.8-0.9 (Hayaloglu et al., 2008), but the values in the current study were lower. As a result, cheeses made from pasture milk with a C/F ratio of 0.67 had better protein recovery and lower whey losses compared to cheeses made from indoor milk with a C/F ratio of 0.79.

Milk from grazing goats also contained significantly more (p<0.05) MU and MUN. Goat milk contains about 28 mg/dL of urea, which is the main component of non-protein nitrogen (Prosser, et al., 2008), but the optimal amount of urea in goat's milk has not yet been precisely defined (Bendelja-Ljoljić, et al., 2020). Bonanno et al. (2013) found that high energy-supplemented diets (concentrate or concentrate+hay) decreased MU content which is consistent with our results. On the other hand, Bonanno et al. (2008), found that the concentration of MUN in milk was positively correlated with the crude protein content of the meal and negatively correlated with the ratio of protein to NDF in the goat feed. The amount of MUN was more variable in indoor milk compared to pasture milk. This is probably due to the lower protein content in concentrate and its higher variation in energy content. In contrast, the amount of SCC varies greatly in both groups of milk samples. These results are also in agreement with the results of previous studies for the same housing system (Paskaš et al., 2020) but are in contrast with the results of Bodnár et al. (2021). Milk samples from the pasture system were of poorer microbiological quality, indicating less appropriate hygiene practices during milking.

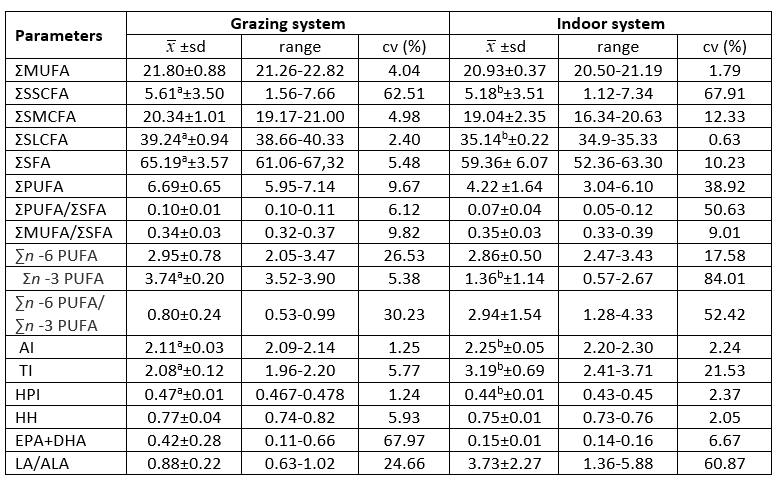

Goat milk fatty acids profile and nutritional indices

Table 3 shows that significant differences (p<0.05) were found in the total content of short and long-chain saturated fatty acids contents and the total sum of saturated fatty acids.

Table 3. Goat milk fatty acid profile and nutritional indices (g/100 g)

MUFA - monounsaturated fatty acids; SSCFA - saturated short-chain fatty acids; SMCFA - saturated medium-chain fatty acids; SLCFA - saturated long-chain fatty acids; SFA - total saturated fatty acids; PUFA - polyunsaturated fatty acids; n -6 PUFA - polyunsaturated n-6 fatty acids; n -3 PUFA - polyunsaturated n -3 fatty acids; AI - аtherogenicity index; TI - thrombogenic index; HPI - health promoting index; HH - hypocholesterolemic/hypercholesterolemic ratio; EPA+DHA - docosahexaenoic₊eicosapentaenoic acids; LA/ALA - linoleic acid/α-linolenic acid ratio; x ± sd - arithmetic mean ± standard deviation; cv - coefficient of variation; Means with different letters are significantly different (p<0.05)

Expressed as a percentage of the total, the PUFA content of milk from grazing and confined goats was estimated to be 7.14 % and 4.99 %, respectively. In addition, milk from the indoor system contained more MUFA (24.77 % vs. 23.27 %), SFA (70.24 % vs. 69.59 %) and particularly SSCFA and SMCFA (6.13 % vs. 5.98 % and 22.53 % vs. 21.71%). In contrast, slightly more SLCFA were found in the milk of grazing goats (41.89 % vs. 41.58 %). Bodnár et al. (2021) reported that pasture feeding had a particularly significant effect on reducing the concentration of medium-chain fatty acids. The results of this study are consistent with ours and those of Bonanno et al. (2013) for MUFA, PUFA and SFA content.

Compared to indoor goat milk, milk from pasture-raised goats had statistically significantly better AI and TI values. In addition, the content of nutritionally more desirable n-3 polyunsaturated fatty acids was significantly higher in the milk from pasture-raised goats. Conversely, milk from confined goats had a higher ratio of n-6/n-3 fatty acids, and a higher ratio of LA/ALA, but the differences were not statistically significant (p<0.05). Data from the literature also indicate that goat grazing significantly reduces the AI and TI in milk and increases the content of n-3 fatty acids (Bodnár et al., 2021; Pajor et al., 2021). A comparison of the values of these indices in the current study with data from the literature shows that both goat husbandry systems studied tend to have lower and more favourable values than those found in the aforementioned literature. Extensive grazing also contributes to higher HPI and H/H index values in goat milk (Bodnár et al., 2021). For dairy products, the range of the HH index is from 0.31 to 1.29 (Chen and Liu, 2020), indicating that goat milk in the present study has excellent health properties. Although EPA and DHA are mostly used to evaluate the nutritional value of seafood (Chen and Liu, 2020) and are less frequently used for dairy products, the EPA+DHA content was also slightly higher in pasture milk in the present study.

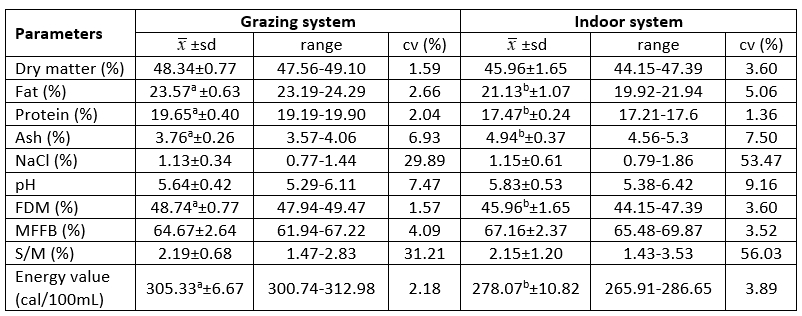

Physicochemical composition of goat white-brined cheese

Table 4 shows the results of the physicochemical analysis of the cheese samples. Pasture goat cheese had significantly higher fat and protein content (p<0.05) which is consistent with the results of Bodnár et al. (2021) and Pajor et al. (2021) for semi-hard goat cheese. Comparing both groups of experimental cheese samples, it was found that dry matter, protein, and NaCl content were higher than in traditional goat white-brined cheese (Mladenović et al., 2021). In particular, fat content was higher in pasture-raised cheese. Inglingstad et al. (2014) reported that goat milk obtained in the early season was more suitable for cheese-making compared to milk obtained from pasture in the late season and had better rennet coagulation, shorter coagulation time, and higher gel strength. Conversely, Kelly et al. (2008) noted that in cheese making, the contribution of milk is very important, but the influence of different technologies or variations within technology, as well as the influence of external agents added to the milk, should not be neglected. The experimental cheeses also differed in their pH values and both cheeses showed large differences in NaCl content. According to the Serbian regulations (2014) and based on the FDM content, the tested samples of the experimental cheeses were classified as full-fat; however, some samples of the cheese from the indoor production system were classified as semi-fat. In terms of MFFB content, the studied cheese samples were classified as semi-hard, but some samples also belonged to the soft cheese group. The S/M ratio varied considerably due to non-standard salting but the average values were similar (2.19 and 2.15, respectively). During the early stages of ripening, the salt concentration near the surface of the cheese is significantly higher, so diffusion of water from the centre outwards predominates over evaporation of surface water. As a result, the difference in moisture content between the outer zone and the central zones is in equilibrium during the early stages of the ripening process (Santapaola et al., 2021).

Table 4. Physicochemical composition of goat white-brined cheese

FDM - fat on a dry matter basis; MFFB - moisture on a fat-free basis; S/M (%) - salt in moisture; x ± sd - arithmetic mean ± standard deviation; cv - coefficient of variation; Means with different letters are significantly different (p <0.05).

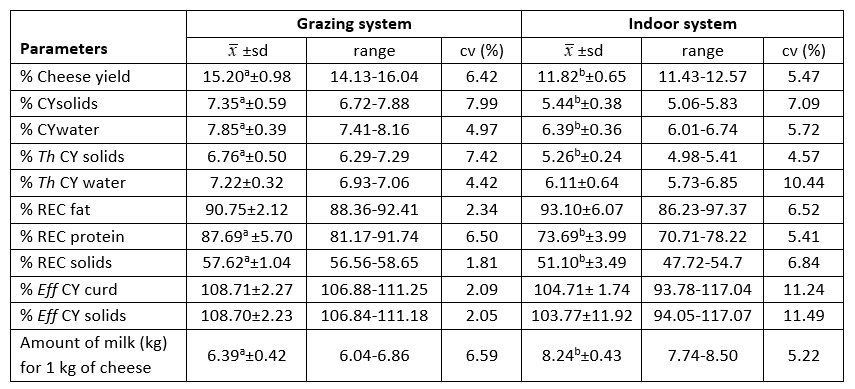

As shown in Table 5, a significant transformation and distribution of nutrients from milk into cheese and whey occur. From the obtained results, %RECfat was higher in the cheese from indoors but a significant difference (p<0.05) was not found. On the other hand, the cheese from the pasture system had significantly higher (p<0.05) values for %RECprotein, %RECsolids and better cheese efficiency. The research study by Vacca et al. (2018) found that husbandry practices had no particular effect on utilization characteristics or actual and theoretical cheese yield and efficiency estimates while they strongly influenced daily goat milk production. However, the study by Pazzola et al. (2018), found that increasing milk protein content increased %RECfat and %RECsolids in curds. Different methods of feeding and raising goats contributed significantly (p<0.05) to the different %CY, and the %CY of pastures was 22.24 % higher than the cheese yield from the indoor system. These results are similar to those of Bonanno et al. (2013) and Bodnár et al. (2021). Cheese yield is particularly important for small-scale cheese producers, as small differences in yield can affect realised profits (Guo et al., 2004).

Table 5. Cheesemaking traits of goat milk

%CY - cheese yield; % Th CY - theoretical cheese yield; % Eff CY - cheesemaking efficiency; % REC - nutrient recovery; x ± sd - arithmetic mean ± standard deviation; cv - coefficient of variation; Means with different letters are significantly different (p <0.05).

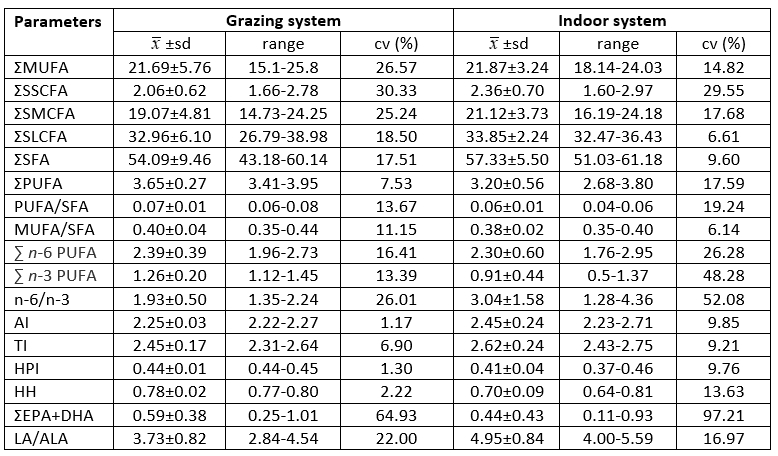

The fatty acid profiles and nutritional indices of the experimental white-brined goat cheeses are presented in Table 6. As for the total content of SFA, MUFA and PUFA in cheeses from the different production systems, no statistically significant difference was found (p<0.05). When these values are expressed as a percentage of the total, the percentage of MUFA and PUFA in pasture-raised cheeses was 27.27 % and 4.59 % respectively, whereas, in cheeses from indoor goats, it was 26.54 % and 3.89 % respectively. The amount of nutritionally less desirable SLCFA was slightly higher in pasture-raised cheese (41.45 % vs. 41.07 %). The percentage of SFA: 69.58 %, SSCFA: 2.89 % and SMCFA: 25.63 % was higher in indoor cheese than in cheese from pasture-raised animals (SFA: 68.02 %, SSCFA: 59.0 %, SMCFA: 23.99 %, respectively).

From a nutritional point of view, the values of the ratio of MUFA and PUFA to SFA were slightly better in cheese from an indoor system, but the differences were small and not statistically significant (p<0.05). Conversely, pasture-raised cheese had more total n-3 fatty acids and more total EPA+DHA. It also had a more favourable AI, TI and n-6/n-3 ratio. This study confirms research by Bodnár et al. (2021) and Klir Šalavardić et al. (2021) showing that grazing reduces AI, LA/ALA and increases HPI and HH levels in semi-hard goat cheeses. According to Rolinec et al. (2018), extensive grazing results in a significantly lower n-6/n-3 ratio in semi-hard goat cheese, which is consistent with our findings. The recommended intake of n-3 fatty acids in the diet of preschool and school age children is 1-1.2 g per day (Šobajić, 2002). The results of the work showed that goat's milk and cheese are good sources of n-3 acids and could contribute to the nutritional well-being of children.

Table 6. Nutritional indices and fatty acid profile of white-brined goat cheese (g/100 g)

MUFA - monounsaturated fatty acids; SSCFA - saturated short-chain fatty acids; SMCFA - saturated medium-chain fatty acids; SLCFA - saturated long-chain fatty acids; SFA - total saturated fatty acids; PUFA-polyunsaturated fatty acids; n -6 PUFA - polyunsaturated n-6 fatty acids; n -3 PUFA - polyunsaturated n -3 fatty acids; AI - аtherogenicity index; TI - thrombogenic index; HPI - health promoting index; HH - hypocholesterolemic/hypercholesterolemic ratio; EPA+DHA - docosahexaenoic₊eicosapentaenoic acids; LA/ALA - linoleic acid/α-linolenic acid ratio; x ± sd - arithmetic mean ± standard deviation; cv - coefficient of variation

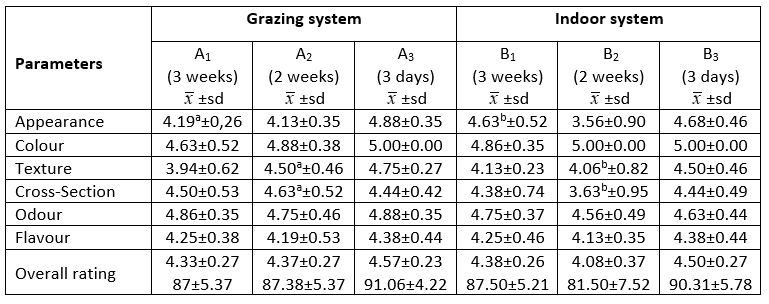

Hedonic scales and preference tests are very effective tools for evaluating product quality from the consumer's point of view. The sensory characteristics of cheese samples at different stages of ripening were evaluated and the results are presented in Table 7. The overall score was statistically significantly different between samples B 1, B 2 and B 3, while samples A 1, A 2 and A 3 showed no difference. The cheese samples with the shortest ripening times had the highest scores (91.06 and 90.31) (Table 7). The flavour, colour, odour, and texture of goat`s cheese are very unique. The intense flavour and odour of goat`s milk sometimes limit the acceptability of its products (Paskaš et al., 2020a) but the odour of the produced cheeses was not noticeable and no significant difference (p<0.05) was found for this attribute. Although the cheese from indoor production contained less fat than the cheese from outdoor production, there was no difference in t

aste between the two. In addition, the cheese made from milk from the indoor system had a softer texture, which affected the lower classes of appearance, cross-section and texture of the cheese, and a significant difference (p<0.05) was found between samples A 2 and B 2. The best-evaluated characteristic of the goat cheese was its white colour, and no atypical colour spots could be observed. The results of this study are consistent with the findings of Mladenović et al. (2021) who examined traditional white-brined goat cheeses, except that no bitterness was observed.

Table 7. Sensory evaluation of goat white-brined cheeses

x ± sd - arithmetic mean ± standard deviation; Means with different letters are significantly different (p<0.05)

Table 8. Goat whey physicochemical composition

x ± sd - arithmetic mean ± standard deviation; cv - coefficient of variation; Means with different letters are significantly different (p<0.05).

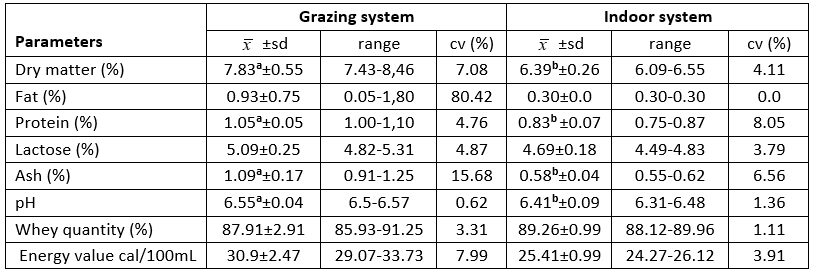

Goat whey quality

The physicochemical composition of whey obtained in the production of white-brined goat cheese is presented in Table 8.

Analysis showed that the whey from grazed goats contained more dry matter, fat and protein. The pH value of whey from grazed goats was also significantly higher (p<0.05). However, in terms of the parameters studied, both types of whey were characterised as sweet. Whey acidity is an important indicator of whey quality (Pandya and Ghodke, 2007), and whey from milk that has undergone thermisation treatment contains more nutrients (Popović-Vranješ et al., 2017). Comparing the results of this study with the composition of whey obtained from pasteurized milk treated at 80 °C/5 min and 90 °C/5 min in the production of white-brined goat cheese (Miloradović et al., 2016), significant differences could be observed. In particular, both types of whey studied contained more protein and dry matter (protein: 0.72 % and 0.50 %; dry matter: 6.16 % and 5.78 %; pasteurized milk treated at 80 °C/5 min and 90 °C/5 min, respectively) (Miloradović et al., 2016). In particular, whey from the pasture system contains a higher percentage of fat (0.58 % and 0.35 %, pasteurized milk treated at 80 °C/5 min and 90 °C/5 min respectively). Mladenović et al. (2021) found that whey that remained in the traditional production of white brine cheese had a higher protein content and a lower fat and dry matter content compared to whey from pasture. Regarding the goat cheese production, processing milk from the indoor system resulted in a greater amount of the remaining . In additon, both approximate values of the amount of whey were higher than the amount of whey obtained in the production of hard goat cheese (Popović-Vranješ et al., 2017).

Conclusions

The results of this study show that the chemical composition of the milk and cheese was strongly influenced by the different husbandry and feeding methods. In particular, pasture milk had on average 32.32 % more milk fat than milk from housed goats. The study also showed large differences in SCC levels and when the results of SCC and TBC levels were considered, the indoor system provided higher milk quality. The results of this study indicate that goat grazing results in higher n-3 fatty acid content in milk and cheese, lower n-6/n-3 ratio, and better nutritional indices. The characteristics of the cheeses produced were highly dependent on the fat, protein and casein content of the milk, with cheeses made from pasture-raised milk having a higher fat, protein and dry matter content. The higher nutrient content of the milk from pasture-raised goats also had a significant effect (p<0.05) on the yield of the experimental cheeses. Pasture-raised cheeses also had higher values for %REC protein, %REC solids and cheese efficiency. Consequently, pasture-raised goats produce milk more suitable for white brine cheeses.

Acknowledgement

The study was supported by the Ministry of Education, Science and Technological Development of the Republic of Serbia (Contract number 451-03-68/2022-14/200143, TR31085).

Utjecaj različitih proizvodnih sustava na kvalitetu kozjeg mlijeka, sira i sirutke

Sažetak

Ovo istraživanje je provedeno kako bi se utvrdio utjecaj hranidbe i različitih proizvodnih sustava na kvalitetu mlijeka, bijelog sira u salamuri i sirutke. Također, cilj je bio utvrditi prikladnost kozjeg mlijeka za proizvodnju bijelog sira u salamuri. Ispitivan je fizikalno-kemijski sastav i higijenska ispravnost sirovog kozjeg mlijeka, profil masnih kiselina i nutritivni pokazatelji mlijeka i bijelih sireva u salamuri. Tradicionalni bijeli sir u salamuri proizveden je od mlijeka koje je izuzeto u tri navrata s dva različita gospodarstva. Rezultati su potvrdili da različiti sustavi uzgoja i hranidbe koza utječu na fizikalno-kemijski sastav mlijeka i sira te njihov profil masnih kiselina. Mlijeko i sir koza držanih na ispaši su sadržavali značajno više (p<0,05) masti, proteina, ukupne suhe tvari te je u proizvodnji sira postignut viši prinos (%CY). Nadalje, nutritivni pokazatelji su bili povoljniji, s nižim vrijednostima indeksa aterogenosti (AI) i trombogenosti (TI), višim indeksima zdravstvene vrijednosti (HPI) i boljim omjerom hipokloseterol/hiperkoletesterol učinka (HH). Ispaša koza utjecala je na više koncentracije n-3 masnih kiselina u mlijeku i siru i nižem omjeru n-6/n-3 masnih kiselina. Učinkovitost proizvodnje sira i postotka zadržavanja proteina u grušu (%REC PROTEIN) su bili bolji za mlijeko s ispaše, dok je postotak zadržane masti u grušu (%REC FAT) bio veći za mlijeko koza iz zatvorenog uzgoja. Potrošači su najboljima ocijenili kozje sireve bez zrenja iz oba sustava proizvodnje. Nadalje, proizvodnja bijelog sira u salamuri rezultirala je kvalitetnom sirutkom, sa značajnim zdravstvenim prednostima. Prirodni pašnjaci nude znatno više prednosti kozama od zatvorenih sustava, osobito u ranim fazama korištenja i doprinose visokoj nutritivnoj vrijednosti kozjeg mlijeka, sira i sirutke.

Ključneriječi: kozje mlijeko; bijeli kozji sir u salamuri; kozja sirutka; profil masnih kiselina