UVOD

Skidding is one of the most expensive and technologically challenging activities of forest exploitation. In many cutting methods, wood is scattered over a relatively large forest area and it is necessary that machinery can reach each piece. It would be impossible, both economically and technologically, to build forest roads or skidding trails for each specific tree. However, they are built only to the point from which each wood piece could be somehow reached and collected by machinery in a technologically and ecologically acceptable way. From this point of view forest transport could be categorised into three phases: winching (collecting), skidding and transportation (Jeličić, 1988). Winching of wood is moving from the stump to the nearest skid trail or route, usually done by a cable winch attached to the skidder. Skidding is moving of wood along the skid trail or route to the forest landing site, on the forest road. It is usually performed by skidders, adapted agricultural tractors, forwarders, or cable yarders, by which wood is driven on wheels or carried in the air. The next phase is transport of wood from the forest landing site to the final consumer or wood processing plant. Long-distance wood transport aims to minimise the transportation cost after determining the points of supplier and customer, as well as determining the decision variables, i.e., transportation routes (Loftalian et al. 2022).

Timber harvesting systems must be adapted to the specificity of a given country, the topography, tree species encountered, timber assortments preferred and expected by the market, as well as the technological, social and economic conditions (Kulak et al. 2023).

Nowadays, in the forestry of Bosnia and Herzegovina, the winching and skidding of forest wood assortments is most often done with skidders equipped with a cable winch. They are most applicable because they can handle hilly, mountainous and inaccessible terrain in the compartments that are most common in the local forestry areas. In addition, a group-selective forest management system is dominant in high forests in Bosnia and Hercegovina, where the movement of any type of machinery is strictly limited to the skid trails and skid roads. It is a matter of legal and sub-legal regulations and environmental standards. In most cases, cable skidders are the only applicable technology for the first transportation phase.

For this reason, it is of great importance to analyse the productivity of these machines as often as possible, to obtain the most efficient solutions in forest harvesting technologies and to increase the profitability of harvesting operations.

The importance and characteristics of the first phase of timber transport have been studied by many researchers, under various conditions and regarding different technologies. In doing so, they came to many conclusions and singled out the most important factors that influence the process. Extraction of wood assortments from the forest is a difficult, risky, expensive and time-consuming operation, especially in mountainous areas. Kluender and Stokes (1996) found that grapple skidders were consistently faster and more productive than cable skidders. However, grapple skidders have not yet been used in Bosnia and Herzegovina because of specific management systems and restrictions on the movement of mechanisation through the forest. Egan and Baumgras (2003) in West Virginia, USA examined the relation among several ground skidding methods and harvested stand characteristics. They found a direct relation between skidding distance and cycle time. Wang et al. (2004) found that the skidding cycle time with Timberjack 460 skidder was mainly affected by load size and skidding distance. Zečić and Marenče (2005) examined characteristics of work and efficiency of a specific work team (working group). They established standard time for two skidders ranging between 25.05 min/m3 for distance of 150 m and 33.20 min/m3 for distance of 650 m. They also established the coefficients of allowance time of 1.29 and 1.24. Allowance time can be considered necessary in the work process, but it is not directly related to immediate work. Most statistical studies on skidding operations indicated that skidding distance, piece size, load volume, winching distance and slope of the trail strongly impact the producitvity in this step of the logging process (Ghaffariyan et al., 2013; Sabo and Poršinsky, 2005). The average load volume of Ecotrac 120V skidder in selective cutting in dominantly beech stands is 5.34 m3 and consists of 5.7 pieces in average, with a length of 7 m and a volume of 0.93 m3 (Horvat et al., 2007). At the hilly working site, the effective time was 8.06 min/m3 and in selective felling the effective time was 9.88 min/m3. Daily productivity ranging from 57.49 to 35.4 m3/day, at distances varying from 100 to 500 m, can be achieved at the hilly working site. At the mountain working site the daily output of 48.53 m3/day to 35.54 m3/day can be achieved for the same distance range (Horvat et al., 2007). Bembenek et al. (2011) showed that the overall average operational productivity during extraction with HSM 904Z skidder was 30.5 m3/h, with an average timber volume of 1.8 m3. The obtained productivity seems to be very good when compared with e.g. 11.6 m3/h achieved by Timberjack 240 C in a mountainous fir stand when skidding very large trees up to 3.9 m3 (Sabo and Poršinsky, 2005). When using a cable skidder LKT81 Turbo in mountain conditions in 82-year-old fir stand, productivity can reach 7.15 m3/h (Porter and Strawa, 2006). As seen from several previous studies, the results obtained are quite variable. It is well known that forestry work is characterised by extremely variable conditions, and it is very difficult, almost impossible, to define and unify all the factors that influence the performance of the work process in every research. If we take into account that there is a lot of different mechanization available, from different manufacturers, with different characteristics, it is clear that there is a need to conduct work productivity research again and again, and to constantly update the results. All phases of forestry work are extremely expensive to perform and any missed opportunity for optimisation is unacceptable. A typical problem for operational forestry sector in Bosnia and Herzegovina is that, due to the lack of investment funds, very outdated mechanization is used, which according to depreciation standards should no longer be used, but is still actively used due to different reasons. It is known that depreciated mechanisation is more prone to breakdowns, which causes work stoppages. However, contractors are either forced to use such mechanisation, or some of them find a justified calculation in the fact that cheap local services and non-original spare parts are available to them. Also, many local workshops have specialised in more complicated jobs, such as designing and finishing entire assemblies, like constructing winches, dozer blades and other machinery. The reason for conducting this study is the intention to determine to what extent skidders of older generation are efficient and comparable to new-generation skidders in terms of productivity.

In this research, the use of two cable skidders, Timberjack 350A and Tree Farmer C5D, was analysed to determine their productivity and applicability in the conditions of group-selective forest management and motor-manual assortment harvesting method. Since investigated skidders are of older generation, the goal was also to determine to what extent they are comparable to the modern skidders in terms of productivity and whether their productivity is in accordance with the working norms applied in responsible forest companies. Collecting the data needed to determine productivity, i.e., to conduct a time and work study, is a difficult and expensive job, and therefore it is necessary to use all possible tools to facilitate this job. The secondary, but also important goal was to investigate how mobile Android application AlpineQuest can simplify field data collection when conducting a time and work study.

MATERIAL I METODE

The study was conducted in compartment 25 (FU “Lješnica Tešanjska”) and compartment 67 (FU “Nemila Prepelari”). Both compartments are in the area of municipality Žepče, and belong to the Public Forest Enterprise “ŠPD-ZDK” Ltd. Zavidovići (Table 1). Compartment 25 is open by one forest road and by a secondary network of skid trails. Compartment 67 is open in the same way. Openness by a secondary network in both compartments is about 150 m/ha.

Table 1. Research site characteristics

Tablica 1. Karakteristike lokacije istraživanja

*Real situation regarding tree species in the field significantly differs from management plans

Two skidders were examined, used for several years in PFE “ŠPD-ZDK” Ltd Zavidovići, but their work has not been examined so far. The skidders are Tree Farmer C5D (1984 p.y.) and Timberjack 350A (1985 p.y.) (Table 2) (Figure 1 and 2). When planning the work for the investigated skidder in the company, the norms normally used for other skidders were applied, which were originally created for the LKT 81 skidder. The goal of this research, among other, was to determine whether the productivity of such skidders is competitive with the provided norms used in the company. Work organisation was 1+1, including a skidder operator and a choker-setter. General cutting intensity for both compartments was 15%, but because of the real field situation in the compartments, marked trees were not equally distributed over the area.

Table 2. Machinery type

Tablica 2. Vrsta strojeva

Figure 1. Tree Farmer C5D skidder

Slika 1. Tree Farmer C5D skider

Figure 2. Timberjack 350A skidder

Slika 2. Timberjack 350A skider

The research was conducted by applying a time and work study. Time study is one of most common practices of work measurements. It is used worldwide, in many types of work analyses in order to determine the input of time in the performance of a piece of work (Björheden, 1991). Time studies can be carried out using continuous time study methods such as continuous or repetitive timing or indirect work sampling (Marčeta, 2015). In this research, continuous timing method was used. Empirical models are generally developed by collecting field data and testing the statistical significance of any relationship with regression analysis. This technique determines the relationship between a dependent variable (typically time consumption or productivity) and one or more independent variables (Costa et al., 2012). Time study is defined as the analysis of methods, material, tools and equipment used in the production process (González, 2005) or as time measurement, classification and data analysis to increase work efficiency (Forest work nomenclature, 1995). The main application of the time study is calculation of productivity. According to Harstela (1993), productivity is the ratio between output (volume of wood) and input (time consumption or funds).

After preliminary research, a recording sheet was created with the following work operations: Unloaded drive, Manoeuvring drive, Pulling out the cable, Hooking, Winching, Forming of load, Loaded drive, Unhooking and Decking. The transport distances achieved during drive of the loaded and unloaded skidder along the skidding trail and stand were measured using the AlpineQuest application. This application is relatively cheap and available for Android and IOS platform (Lepoglavec et al., 2019). It can be installed on any new-generation smartphone. AlpineQuest is a comprehensive application for navigation. It allows users to explore and navigate activities like hiking, trekking, camping, and geocaching. With offline map support, users can download and store maps directly on their device (mobile phones), ensuring accessibility in areas with limited internet connectivity. The app features GPS tracking, waypoints, and route creation, enabling users to mark locations and record tracks. Geocaching enthusiasts can import and export GPX files from Global Mapper, QGIS, or other GIS software, making it easier to discover hidden caches. AlpineQuest includes a digital compass, customisable map styles, and integration with external devices. AlpineQuest can also be used in forestry applications. While it is primarily designed as an outdoor navigation tool, its features and functionalities can be of benefit to forestry professionals. It allows users to download and store maps offline, which is particularly useful in remote forest areas with limited or no internet connectivity. The app's GPS tracking feature enables forestry professionals to accurately track their location and movements while working in the field. Forestry workers can mark waypoints and create routes in AlpineQuest to document important locations such as tree stands, skid trail routes, survey points, or boundary markers. This feature helps in navigation and ensures that key areas are easily identifiable and accessible during fieldwork. Forestry professionals can import their own forestry-specific maps or overlay relevant information such as tree types, forest boundaries, or infrastructure onto the maps. This capability allows for efficient data collection and analysis during forestry surveys or assessments. The app's elevation profiling feature is valuable for forestry applications, as it provides insights into the topography and slope gradients of the forested areas. This information can aid in planning logging operations, assessing potential hazards, or understanding the landscape's characteristics.

REZULTATI I DISKUSIJA

Tree Farmer C5D was used in compartment 25, where 28 cycles were recorded, during which 107 G were skidded with an average diameter (d) of 53.3 cm. Total volume of skidded wood was 140.18 m3 with average volume of 5.01 m3/cycle. Timberjack 350A was used in compartment 67, where 29 cycles were recorded, during which 151 logs were skidded with an average log diameter of 44.4 cm and length of 6.76 m, where total volume of skidded wood was 151.86 m3 with average volume of 5.24 m3/cycle (Table 3). The load mainly consisted of 2 or 3 logs in compartment 25, and 4 or 5 logs in compartment 67.

Table 3. Load parameters

Tablica 3. Parametri tereta

Distances were measured with AlpineQuest application for Android phones. Average skidding distances for loaded drive were 526.25 m for Tree Farmer C5D and 491.21 m for Timberjack 350A (Table 4). Distances varied from 220 m to 900 m for Tree Farmer C5D, and from 300 m to 680 m for Timberjack 350A.

The distances were relatively long, longer than it is usually recommended for cable skidders. This is caused by the location of forest roads and landing sites in the compartment. Shorter skidding distances are generally preferred as they help to reduce the amount of soil disturbance, minimise the risk of mechanisation damage, and improve the overall efficiency of the skidding (Mousavi et al., 2013).

Average Manoeuvring drive distance recorded for Tree Farmer C5D was shorter than for Timberjack 350A, 23.64 m versus 13.94 m, respectively, while the situation with the Winching distance was the opposite, amounting to 23.31 m versus 10.79 m.

Table 4. Distance parameters

Tablica 4. Parametri distanci

Total productive working time recorded for Tree Farmer C5D was 773.38 min. Each work operation was separately analysed. The most time-consuming were Unloaded drive (222.34 min) and Loaded drive (203.89 min), followed by Decking (80.65 min). Regarding Timberjack 350A, productive working time was 1002.8 min, of which Unloaded drive accounted for 291.70 min and Loaded drive for 244.57 min, followed by Winching (99.95 min). Other work operations took less individual time.

The relative share of work operations is shown in Figure 3, where it can be seen that in both cases the distribution is similar, which is to some extent expected, since the skidders that were investigated are of relatively similar construction, with a comparable organisation of work and work conditions (Table 1).

a

b

Figure 3. Relative share of working operations in productive working time - (a) Tree Farmer C5D; (b) Timberjack 350A

Slika 3. Relativni udio radnih operacija u produktivnom radnom vremenu - (a) Tree Farmer C5D; (b) Timberjack 350A

Multiple regression with dummy variables was performed to examine whether skidder type and skidding distance influence the effective time per cycle. The results indicated that both distance and skidder type had a statistically significant influence (p<0.005) on the working process and the conclusion was that further analysis should be done for both skidders separately (Table 5).

Table 5. Multiple regression with dummy variables

Tablica 5. Multipla regresija s kategoričkim varijablama

Analysis of variance showed very strong reliability of regression model (Table 6).

Table 6. Analysis of variance for cycles time

Tablica 6. Analiza varijance za vrijeme ciklusa

| Effect | ANOVA; min/cycle | ||||

|---|---|---|---|---|---|

| Sum. of Squares | df | Mean Squares | F | p-value | |

| Regress. | 4636.797 | 2 | 2318.399 | 172.3195 | 0.0000 |

| Residual | 726.520 | 54 | 13.454 | ||

| Total | 5363.317 | ||||

In order to examine the influence of different working factors on the duration of specific working operations, the regression analysis was performed, in which factors were independent variables and working operations were dependent variables. Determination of factors for regression was based on whether dependence is expected to be shown or not and on the previous studies (Marčeta et al., 2014; Kulak et al., 2017, Knezevic et al., 2018). In the cases where dependence was proven, mathematical model was established, and where there was no statistically significant dependence, the average value was taken in further calculations. In Table 7 it can be seen that Unloaded drive, Manoeuvring drive and Loaded drive showed dependence on corresponding distances, while the quadratic or linear equation represents models. The situation is similar with both skidders.

Table 7. Time dependence analysis

Tablica 7. Analiza zavisnosti vremena

Since the establishing of relevant allowance time would require a much larger scale of recording than this study, allowance time factors obtained in similar studies were adopted. The coefficient of 1.30 was used for both skidders, based on studies by Horvat et al. (2007), Marčeta et al. (2014), and Knežević et al. (2018).

Standard time was calculated in the way that time for each work operation was calculated with regression equation for cases where significant dependence of influencing factors was established or using the average values if there was no dependence. The sum of work operation time was multiplied by allowance time coefficient and divided by the volume of skidded load. Productivity was an inverse value, adjusted to a 8-hour working day.

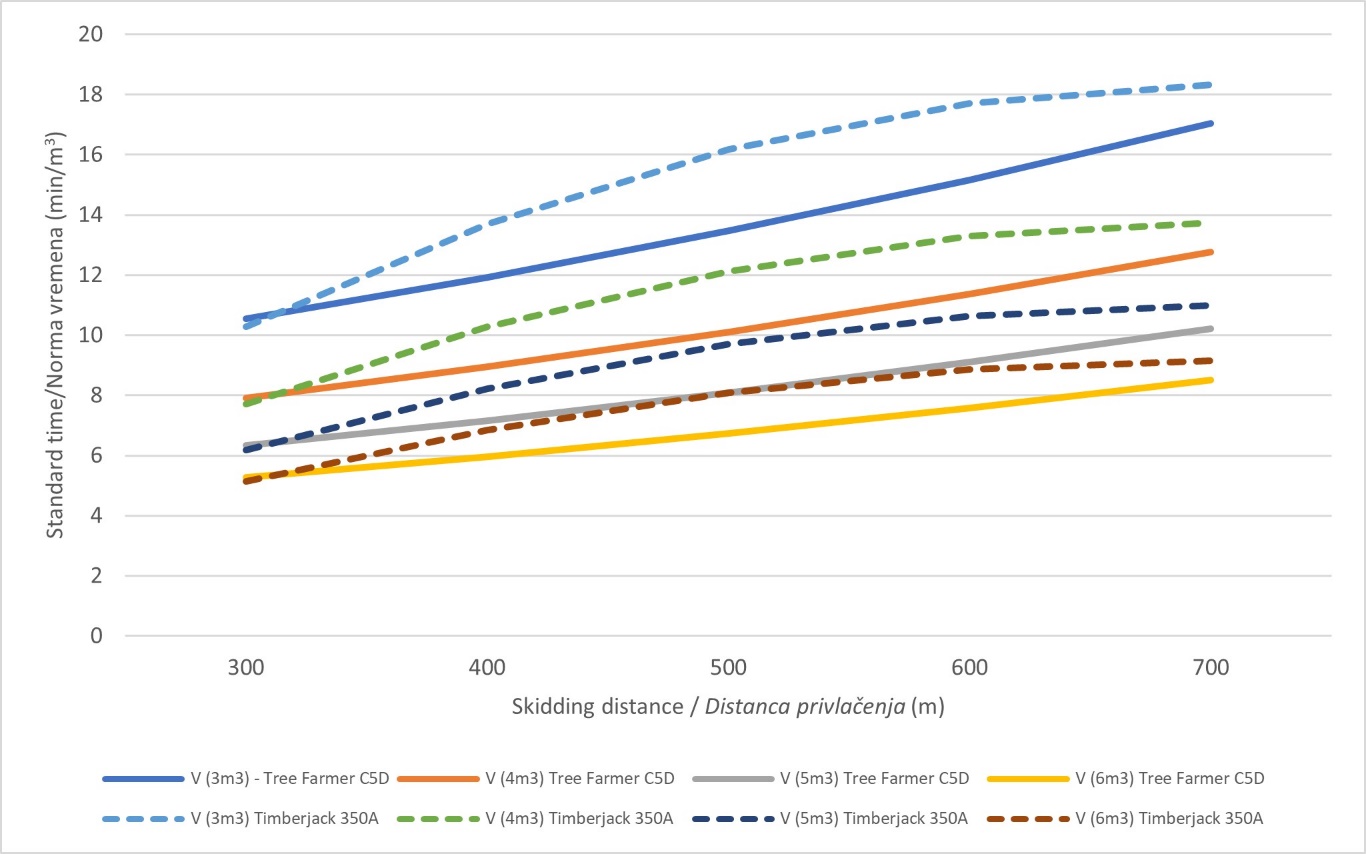

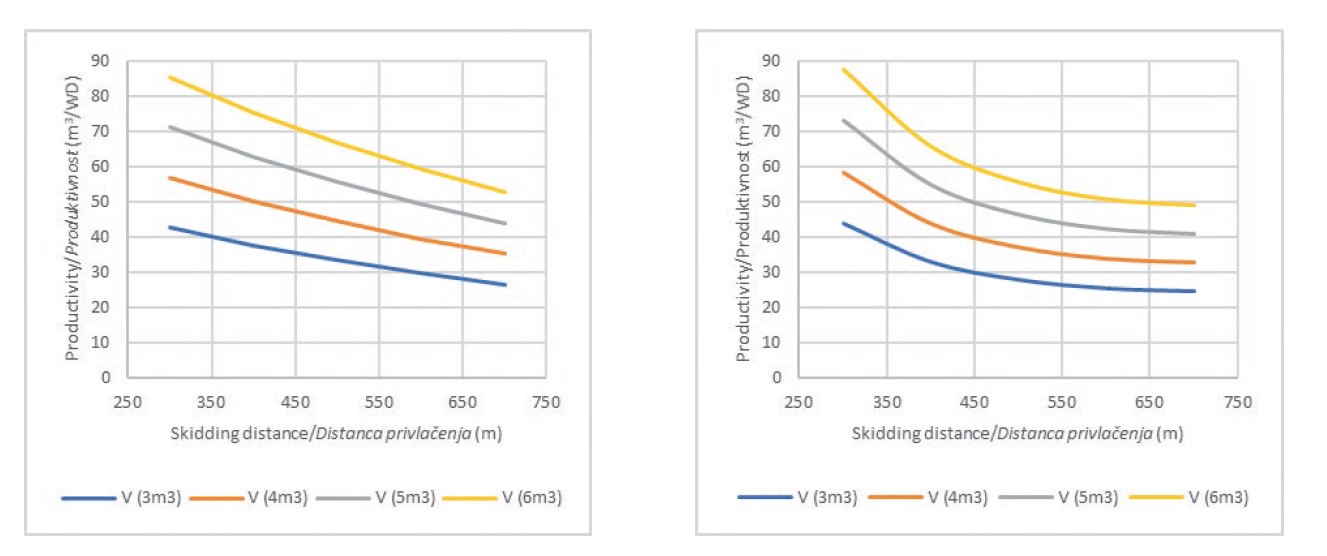

Standard times were used for different load volume and skidding distances, while for fixed winching distance of 30 m the data are presented in Figure 4. It can be seen that with the increase of the distance and volume of the load, the time required for skidding per unit of product also increases. The productivity of skidders based on distance and load volume per 8-hour working day (WD) is presented in Figure 5.

Figure 4. Standard time for winching distance of 30 m

Slika 4. Norma vremena za distancu primicanja od 30 m

a b

Figure 5. The productivity of skidders based on distance and load size - (a) Tree Farmer C5D; (b) Timberjack 350A

Slika 5. Produktivnost skidera na osnovi distance i zapremine tereta - (a) Tree Farmer C5D; (b) Timberjack 350A

According to Horvat (2007), the average load size achieved by skidding with Ecotrac 120V in selective cuttings in beech stands is 5.34 m3, with average 5.7 pieces by load. The average length of the piece was 7 m and volume was 0.93 m3. Comparing the results for the Timberjack 350A in relation to the Ecotrac 120V, a slightly smaller average load volume of 5.24 m3 and slightly fewer pieces per round (5.24) were obtained. For Tree Farmer C5D, the results showed that the average load volume was 5.01 m3, with an average length of 6.63 m per piece, while the average number of pieces was 3.82 per load. Horvat et al (2007) established that Ecotrac 120V achieved productivity from 48.27 m3/day for the distance of 100 m to 35.54 m3/day for distance of 500 m. By analysing the results of Tree Farmer C5D skidder at the distance of 500 m, for an average load volume of 5 m3, an average output of 55,7 m3/day was obtained, which is 20,16 m3/day more than for Ecotrac 120V. For Timberjack 350A at the distance 500 m for an average load volume of 5 m3, a productivity of 46,38 m3/day was obtained, which is 10.84 m3/day more than the results achieved by Ecotrac 120V. According to Horvat et al. (2007), for Ecotrac 120V skidder in mountain conditions, effective standard times from 9.94 min/m3 to 13.51 min/m3 were achieved. In this research, For Timberjack 350A, an effective standard time of 9.12 min/m3 was achieved, while for Tree Farmer C5D it was slightly lower and amounted to 8.97 min/m3. According to Sabo and Poršinsky (2005), for Timberjack 240C skidder, the average work productivity obtained was higher compared to this research and amounted to 11.6 m3/h in mountain conditions. Porter and Strawa (2006) investigated LKT 81T skidder in mountain relief in a fir stand, and evidenced a productivity of 7.15 m3/h, which is comparable to this research. Marčeta (2015) found daily productivity of 46.3 m3/h for the distance of 500 m and a load volume of 5 m3 for LKT 81T skidder in a beech forest.

Comparing the productivity obtained from the time study with the one predicted in the projects of work implementation in the investigated conditions, it was found that in compartment 25, where the Tree Farmer C5D skidder was used, average productivity of 31.18 m3/day was predicted, while 50 m3/day was achieved. In compartment 67, where the Timberjack 350A skidder was used, the average daily productivity was predicted to be 36.08 m3/day, while the actual productivity was 44 m3/day. For the previous comparison productivity found in this research could not be used, because the sample was relatively small. Instead of that, data from working sheets were used, obtained after skidding in the compartments.

ZAKLJUČCI

The results of this research showed that older-generation skidders could be partially competitive with new-generation skidders when it comes to productivity, but for credible conclusions much more detailed investigation should be done. When considered from the point of view of construction, engine power, winch, and other morphological characteristics, it could be said that nothing essential has changed in the construction of skidders in the last decade. However, there are also many other features, such as ergonomic, ecological and some at first glance invisible technological changes that give the newer skidders a significant advantage. What is a big challenge for local forestry companies is that the official norms that have been used for a long time have been overcome, and they provide completely unreliable data about the time required for the execution of work, from which it follows that the accuracy of the economic plan is also questionable. The use of the AlpineQuest application in data collection during the time and work study has proven to be very successful. It found its greatest use in measuring the winching and skidding distances, but it also generally facilitated workers' orientation and movement in area.