Introduction

Circular economy is an economic system that works on regenerating natural systems, preserving products, consumables and materials, while simultaneously reducing waste and environmental pollution. In recent years, the reduction of food waste has been one of the most critical issues for the sustainability of the food sector (Zhang et al., 2022).

Food production and consumption currently operate within an unsustainable linear model. Large amounts of energy, water and natural resources are used to grow and harvest crops, feed animals and produce packaged foods (Ryen and Callie, 2020). The creation of large amounts of waste after food production is a global problem that requires serious organization and management of this waste.

This problem is particularly highlighted in developing countries, due to the large amounts of waste that are created and the lack of well-defined policies for dealing with this type of waste (Moliterni et al., 2022). The production of vegetable oils, as well as other branches of the food industry, generates significant amounts of waste. These wastes can actually serve as raw materials for the production of new products with high added value (Petrović et al., 2022). Industrial hemp (Cannabis sativa L.) is one of the oldest crops grown throughout the flower, which is used to produce high-quality fibre, oil and biomass that are used in various industries: construction, paper, phytoremediation, food and feed for animals, drugs, nutritional supplements and cosmetics (Fiorini et al., 2019;Todd et al., 2022). It is recognized as a new, underdeveloped industrial oil crop in the European Union. Industrial hemp is characterized by traces of δ-9-tetrahydrocannabinol (THC) (<0.3%), which cannot cause intoxication and is therefore suitable for agricultural production. Furthermore, THC and other cannabinoids are recognized as potent lipophilic antioxidants that are associated with certain therapeutic potential (Oreopoulou and Tzia, 2007). Due to the high amounts of proteins, dietary fibres and biologically active substances that have a positive effect on human health, the residues after the production of hemp oil (peels, seeds, defatted oil seed meals, and oil sludge) can be used as a secondary raw material for the production of new functional foods: bread (mostly gluten-free), (Jagelaviciute and Cizeikiene, 2021), pork loaves (Zając et al., 2019) beef burgers (Botella-Martínez et al., 2022), consumed by humans or as feed (Pojić et al., 2014).

Yoghurt is one of the most common fermented milk products due to its nutritional value and pleasant taste. The inclusion of various probiotics, prebiotics, dietary fiber and other additives to it make yoghurt a good matrix for the production of functional food products (Basiri et al., 2022).

Due to the lack of scientific information, the purpose of this article is to present the possibilities for the utilization of the secondary products (defatted oil seed meals) obtained after the production of hemp oil and added to a cow's yoghurt matrix. This type of by-products is very bitter. For better sensory characteristics (taste, odour and overall acceptance) polyfloral honey was added.

Material and methods

Material

Raw cow milk was obtained from a local dairy plant in Pelagonia region (R.N. Macedonia). Physico-chemical properties of raw milk were determinated by Lactoscan MCCW-V1 an ultrasonic milk analyser (Milkotronic LTD. - Lactoscan, Bulgaria). Cow's milk with the following chemical composition was used to produce the different types of probiotic yoghurt: fats: 3.31±0.08%; SNF (solids-not-fat) 7.33±0.01%; density 1,025.87±0.01 g/cm3; lactose 4.71±0.01% solids 0.61±0.01% and proteins 2.69±0.01%. The hemp flour was obtained from the press cake left after the production of hemp oil by cold pressing the seeds of Cannabis sativa L. The press cake was dried at 45 °C for 48 hours and ground into flour. The hemp flour was sieved through a 200 μm sieve and the fraction that fell through (< 200 μm) was used for further analysis and yoghurt production. This flour contained: lipids (11g/100g), carbohydrates (3.7 g/100g), fibers (34g/100g) and protein (40g/100g). A thermophilic culture CHR Hansen ABT-5 Natural Yoghurt Starter Culture with extra Probiotics was used for the production of the probiotic yoghurts. The bacteria strains in this probiotic yoghurt were Lactobacillus acidophilus (LA-5)®, Bifidobacterium animalis subsp. lactis (BB-12)® and Streptococcus thermophilus. These lactic acid bacteria are characterized by fast fermenting and giving a medium-tangy flavour and medium viscosity. Polyfloral honey form Pelagonia region in R.N. Macedonia (16.87±0.04% moisture, 37.32±0.25 mg GAE/mL total polyphenols, and 26.98±1.32% inhibition of DPPH) was used for better organoleptic characteristics of probiotic yoghurt.

Methods

Production of probiotic yoghurt

Pasteurized cow’s milk (80±1 ºС, 40 min) was used for probiotic yoghurt production, using small-scale commercial batch pasteurizer for pasteurization (Weck Inc., Luray, VA). In total, three batches of pasteurized milk (10 L) were produced from the same milk under the same conditions in the Laboratory of milk and dairy products at the Faculty of Biotechnical Sciences in Bitola, R.S. Macedonia. The pasteurization conditions were set according to instruction manual for ABT-5 thermophilic culture with slight modifications. After pasteurization, the milk is cooled to 43 ºС first and 5% (w/v) honey is added into it. When honey was completely dissolved, starter cultures for direct inoculation of the milk (DVS-Direct Vat Set) were used for fermentation (2%) according to producer products information’s (500U/2500L) by homogenizing (40 s at 1200 rpm). Hemp press cake flour (HPCF) 2, 4, 6, 8 and 10 g/100 g were pre-weighed into sterile plastic cups. Samples were incubated in yoghurt making units (Elecrem, Y 140), and after reaching pH 4.6±0.1 (240 min), the obtained probiotic yoghurts were allowed to cool at 4 ºС for 24 h in a refrigerator. In this way, six types of probiotic yoghurt were obtained: five with different HPCF contents (2, 4, 6, 8, and 10%) and a control probiotic yoghurt (0% HPCF). Total volume of milk during the incubation of enriched probiotic yoghurt was 100 mL. The total numbers of yoghurt samples per batch were 96 samples. All analysis was performed in duplicates.

Changes in pH during incubation of probiotic yoghurt

Using a pH meter Testo 206-pH (Testo SE & Co. KGaA, Lenzkirch, Germany), during the incubation (240 min) of the yoghurt, the pH values of the different types of probiotic yoghurt were examined (every 60 min).

Colour of fermented probiotic yoghurt

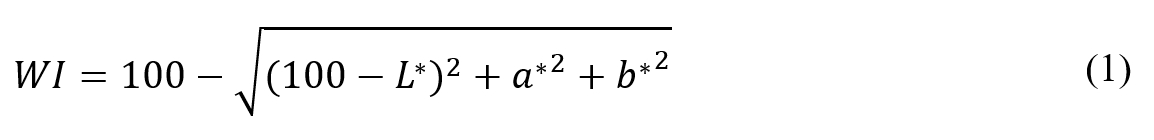

The colour of the enriched probiotic yoghurts with HPCF was determined by the CIE Lab system, with the determination of the L* (brightness), a* (+red/-green) and b* (+yellow/-blue) parameters according to CIE1976 colour system. The overall colour change (ΔE) between the control probiotic yoghurt and the yoghurts with different HPCF content was also determined. If ΔE<1 the difference between colours is not visible to the human eye, when 1<ΔE<3 the colour differences are not considered significant to the human eye, and if ΔE>3 the colour differences are considered visible to the human eye (Pojić et al., 2014). Colour indices (for white, yellow and brown index, Eq. 1, 2 and 3 respectively) were calculated according to (Pathare et al., 2013). The L*, a* and b*colour components were used in the calculation of these indices. The whiteness index (WI) indicates how white the food product appears to humans, in this case probiotic yoghurt. The yellowness index (YI) indicates how much the colour of the probiotic yoghurt changes from white to yellow after adding different amounts of the additive. The brown index (BI) is generally affected by the oxidation of the phenolic compounds in the HPCF supplement, with the quinone compounds changing to brown. Probiotic yoghurt contains little or no long-chain menaquinones. Their amount may increase, depending on how much of the additive is put into it.

Evaluation of the effect of HPCF supplementation on main characteristics of probiotic yoghurt

The Principal component analysis (PCA) method used by (Mladenov, 2020) can be applied in determining which probiotic yoghurt characteristics are affected by the addition of HPCF. The number of principal components is chosen in such a way that they describe more than 95% of the variance in the experimental data.Table 1 shows the HPCF trait-quantity combinations. Before processing with the indicated PCA method, the data describing the yoghurt characteristics were normalized to the interval [0, 1]. Normalization is necessary due to the fact that if some variables have a large variance and others have a small variance, PCA increases the variance in them and this causes the already large variances to increase. This will, of course, result in results with low accuracy.

Determining the appropriate amount of HPCF

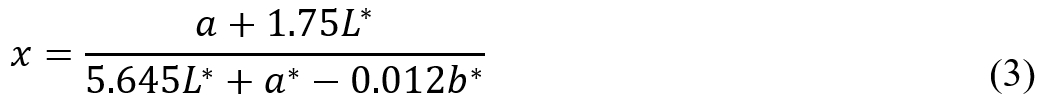

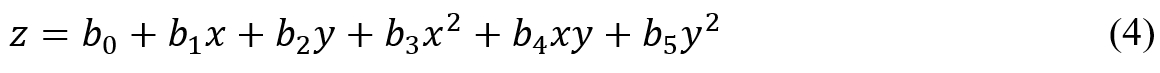

The data from the vector consisting of 15 probiotic yoghurt features (L*, a*, b*, ΔE, WI, YI, BI, pH, AOA, TPC, flavour, mouth-feel, appearance, texture, overall assessment score) were reduced to two principal components. A regression model applied to the analysis of food products was used (Georgieva et al., 2020). It describes the relationship between both independent and dependent variables and has the form (eq. 3 and 4):

to fulfill one of the conditions:

An interior-point-legacy linear programming algorithm was used. A suitable solution is achieved by the algorithm after traversing the interior of the data region in the resulting model. Matlab 2017b software system was used for data processing (The Mathworks Inc., Natick, MA, USA.).

Total polyphenols (TPC) and antioxidant activity (AOA)

To determine the total polyphenols and antioxidant activity of probiotic yoghurts with different HPCF content, an extraction was performed by mixing 10 g of the sample on a magnetic stirrer with 30 mL of 80:20 (methanol: water) for 30 min. The entire amount was then transferred to a centrifuge tube and centrifuged at 8000 min-1 at 4 ºC for 30 min. Of the resulting aliquot, 0.3 mL was homogenized with 1.5 mL of Folin-Ciocalteu reagent (1:10). After 5 min, 1.5 mL Na2CO3 (6%) was added. The resulting solutions are mixed with a vortex and left in the dark for 90 min. After the reaction time, the absorbance of the samples at 760 nm was read using a spectrophotometer UV-VIS Spectrophotometer - UV-1800 (Shimadzu, Japan). Distilled water was used as a control. Results are presented as mg gallic acid equivalent (GAE)/mL. To determine the antioxidant activity, 0.2 mL of the obtained aliquot was taken and homogenized with a previously prepared solution of 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical in methanol (0.1 mM). The obtained samples are homogenized with a vortex and left in the dark for 30 min. Absorbance was measured at 517 nm using a spectrophotometer (UV-VIS Spectrophotometer - UV-1800, Shimadzu, Japan). Methanol was used as a control. Antioxidant activity was determined as a percentage of free radical inhibition using equation (5):

where:

A0 - Absorption of DPHH solution,

A1 - Sample absorbance.

Organoleptic evaluation

Organoleptic or consumer evaluation of the control yoghurt and the new HPCF-enriched probiotic yoghurts was done by 20 semi-trained panellists. A hedonic scale from 1 (Dislike Extremely) to 9 (Like Extremely) was used to evaluate the parameters: flavour, mouth-feel, appearance, texture and overall acceptance.

Results and discussion

The pH values of the probiotic yoghurts with and without HPCF during incubation at 43.0±1.0 ºС are presented inFigure 1. It can be seen that the values decrease with the extension of the incubation time.

According toFigure 1, despite the same initial pH value (6.5), probiotic yoghurts with different HPCF content had different rates of decrease in pH values. After 240 min of incubation, the addition of HPCF lead to a delay in the pH decrease of probiotic yoghurts. HPCF is rich in nutrients and dietary fibre, making it a good source of carbohydrates. These substances are necessary for the survival or growth of lactic acid bacteria (Basiri et al., 2022). The decrease in pH (4.3-4.6) during the storage period of probiotic yoghurt is expected, due to the fact that during fermentation, lactic acid bacteria grow and produce lactic acid, which causes a decrease in pH values and denaturation of the milk protein, as at this time, the characteristic taste and texture of probiotic yoghurt is created and the growth of pathogenic bacteria is inhibited (Tang et al., 2022). The pH of probiotic yoghurt is an indirect indicator of the growth of lactic acid bacteria, when their growth is inhibited, no decrease in pH is observed. Probiotic yoghurts containing HPCF had a higher pH value compared to the control, which may indicate that HPCF could have a slight inhibitory effect on lactic acid bacteria during fermentation. A higher pH compared to the control was also observed by other authors who added different wastes of plant origin such as: cinnamon (Tang et al., 2022), linseed (Basiri et al., 2022), rosehip (Sahingil and Hayaloglu, 2022), thereby enriching probiotic yoghurt.

Colour of fermented probiotic yoghurt

Very often, whether a food product will be preferred and consumed depends on the product's colour and appearance, which are functions of the product's quality. Colour is the first organoleptic characteristic perceived by the consumer, and colour itself can alter taste and aroma perceptions (Sahingil and Hayaloglu, 2022).Table 2 presents the values for the parameters L*, a*, b*, ΔE, WI, YI and BI of the yoghurts with and without HPCF.

L* (brightness), a* (+red/-green) and b* (+yellow/-blue). ΔE<1 the difference between colours is not visible to the human eye, when 1<ΔE<3 the colour differences are not considered significant to the human eye, and if ΔE>3 the colour differences are considered visible to the human eye. Means followed by different letters in the same row are significantly different at p<0.05 following Fisher's LSD test.

The values for L*, a* and b* of the control sample (80.24; -2.63 and 0.43 respectively) were statistically different (p<0.05) compared to the values for the fermented milks in which HPCF was added. The tendency of decreasing values for parameter L* indicates that probiotic yoghurts become darker with increasing HPCF content. The minimal increase in the values for the a* parameter with the addition of hemp flour in other food products was also found by (Ertaş and Aslan, 2020). The increase in yellow fractions could be the high content of γ-tocopherol in hemp oil, and HPCF was obtained from the residues after oil extraction (Pojić et al., 2014). The colour change (ΔE) was compared to the control sample and it was seen that even with the addition of 2% HPCF in the probiotic yoghurt, the change was visible to the human eye (ΔE>3.0).Table 2 plots the colour index values calculated from the components of the Lab model. In the control sample, the white index tends to 0, indicating that it is visibly white in colour. As the amount of adding HPCF increases, the colour of the samples moves significantly away from white. The index of yellow decreases and that of brown increases its values. This is indicative that the samples acquire a yellow-brown colour, which tends to a higher degree to brown, as the amount of additive increases.

Table 3 plots the normalized data for the trait-quantity HPCF. The table consists of six columns and 15 rows. This shows that row-wise the data can be reduced to 14 principal components and column-wise to 5 components. The required number was chosen so that the variance in the data was described above 95%.

Where: ΔE - colour difference; WI - white index; YI - yellow index; BI - browning index; AOA - antioxidant activity; TPC - total phenol content.

Evaluation of the effect of HPCF supplementation on main characteristics of yoghurt

Figure 2 shows the results of the PCA analysis. It can be seen from the graph that the most significant changes in the a* (Lab) component are observed with the addition of 2% HPCF. It can also be considered that the addition of 2% HPCF has no significant effect on the basic characteristics of probiotic yoghurt. Most of the organoleptic characteristics, such as appearance, texture and overall evaluation, were close to the control sample. These indicate that increasing the amount of the additive does not significantly affect them. Those characteristics that are close to the origin of the coordinate system are affected to the greatest extent relative to the others, when changing the amount of HPCF additive. The addition of 4-10% HPCF has a significant effect on the physicochemical characteristics of probiotic yoghurt.

The vector of 15 features of probiotic yoghurt is reduced to two principal components. As observed from the preceding results, they describe over 95% of the variance in the data. The first two principal components were used as independent variables to construct a regression model. After removing the insignificant coefficients from the basic model, this model has the form (eq.6):

The model has a coefficient of determination R2=0.97; standard error is SE=0.68; the level of significance is p<0.02; according to Fisher's criterion F (3, 2) = 48.56>Fcr = 19.16. Therefore, the resulting model describes the experimental data with sufficient accuracy. From the calculations and analysis by linpprog method, it was found that the amount of 4.04% HPCF added in probiotic yoghurt can be considered acceptable to consumers and does not significantly change the physicochemical, colour and organoleptic characteristics of probiotic yoghurt.Figure 3 shows a general view of the resulting model with the appropriate amount of HPCF in probiotic yoghurt applied to it.

Total polyphenols and antioxidant activity of probiotic yoghurt

Phenolic compounds have antioxidant activity and possess anti-inflammatory, anti-cancer, antimicrobial, anti-tumour and anti-ulcer properties (Alenisan et al., 2017). The results presented inFigure 4a show a statistically significant (p<0.05) increase in the content of total polyphenols with the addition of HPCF.

Several authors have reported that the addition of various additives of vegetable origin to yoghurt leads to an increase in the content of total polyphenols content (TPC) in yoghurt.Shori (2022) found that the amount of TPC in yoghurt with added extract of nutmeg, white and black pepper was higher compared to the content of TPC in plain yoghurt.

Dairy products are one of the most interesting products in terms of their potential antioxidant activity, primarily due to the wide variety of antioxidant molecules (milk casein and whey proteins) they contain. Additionally, milk also contains traces of low molecular weight thiols, ascorbate, tocopherol, retinol (vitamin A1), carotenoids, etc. compounds that exhibit antioxidant activity (Alenisan et al., 2017). The addition of HPCF showed that the antioxidant activity increased from 32.2% in the control probiotic yoghurt to 36.0%; 38.7%; 47.4%; 53.0% and 55.6% for probiotic yoghurt with 2%, 4%, 6%, 8% and 10% HPCF respectively. According to Mikulec et al., 2019, the addition of HPCF certainly contributes to the improvement of the antioxidant properties of food products.

Sensory evaluation

The results of the sensory analysis are presented inFigure 5. The following parameters were investigated: flavour, mouth-feel, appearance, texture and overall acceptance. For all characteristics investigated, the panellists determined that the sample with 4% HPCF had the best sensory qualities. From the results presented, it could be obserevd that the panellists rated probiotic yoghurt containing up to 6% HPCF with a score higher than 5. The samples with higher content (8% and 10%) of HPCF were evaluated with much lower scores lower than 5.Dabija et al. (2018) studied the addition of different proteins of plant origin in yoghurt. Among others, they also used natural hemp protein in a concentration of 2.79%. Sensory analysis found this yoghurt to have an overall sensory score of 18.6/20.0. According to these analyses, the amount of HPCF that would be added to yoghurt should not be very high.Ertaş and Aslan (2020) have investigated the addition of various plant extracts and thus enriched yoghurt. The authors found that adding black pepper extract to yoghurt was more acceptable to the panellists than the white pepper extract.

Conclusion

This study provides a new insight into the potential use of hemp press cake flour (HPCF) as an enriched compound in milk to produce probiotic yoghurt. It was found that the addition of HPCF to probiotic yoghurt reduces pH during the incubation of the samples. The addition of HPCF caused an increase in the total polyphenol content and the antioxidant activity of probiotic yoghurt. PCA analysis showed that the addition of HPCF in the amount of 2% did not affect the basic characteristics of probiotic yoghurt, while the amounts of 4 to 10% HPCF had a significant effect on the physicochemical properties (pH, colour, total polyphenols and antioxidant activity) of probiotic yoghurt. According to the regression model, the optimal amount of HPCF that can be added to probiotic yoghurt is 4.04%, which is almost the same amount determined during the sensory analysis as 4%. The results obtained reflect the circular economy by reducing the disposal of these wastes from the production of hemp oil by using them to obtain a promising raw material that can be used to improve the functional properties of probiotic yoghurt.