Introduction

Butter is a high-fat product and contains the same ingredients as milk, but in different ratio. During the churning process, fat and dissolved vitamins A, D and E are concentrated (Yan and Holden, 2018). The dominant component of milk fat (60-65%) is saturated fatty acids (SFA), which differ in structure. The fatty acid (FA) profile of milk fat plays an important nutritional role. The FA profile of dairy fat is important for the nutritional quality of dairy products. A unique feature of milk fat is the presence of short- and medium-chain fatty acids, which are produced by ruminant microorganisms, and are not present in other edible fats. The human body absorbs about 97% of milk fat (Laučienė et al., 2019). The consumption of milk fat is not always associated with high risk of developing cardiovascular disease (CVD). In addition, recent research indicates that milk fat is a natural source of bioactive ingredients (Gómez-Cortés et al., 2018). Hence, butter can be seen as a functional dairy product desirable to consumers. The main butter characteristics include desirable flavour and natural image, while features that can significantly differentiate are colour intensity; diacetyl, cooked, grassy, and milk fat flavours, and salty taste. As many as 89% of consumers consider butter a natural product (Krause et al., 2007).

There are few examples on the market of butter enrichment, and, thus, its pro-health value. Vitamins, such as beta-carotene are most often added as isolated compounds or extracts. Introduction of carrot powder improves the organoleptic properties, structure and consistency of butter (Rashevska and Vasheka, 2011). Studies have also examined butter produced from milk fortified with α-linolenic acid (You et al., 2020). Such fortification can provide benefits against obesity-induced inflammation and insulin resistance (Fan et al., 2020). The studies ofVidanagamage et al. (2016) showed that cinnamon extract (Cinnamomum verum) can be used to formulate an antioxidant rich butter and placed as a natural preservative. In turn,Thakaeng et al. (2020) researched butter with enhanced nutritional and microbiological properties through the addition of green tea (Camellia sinensis L.) extract. Additionally, extracts from tomato processing by-products, rich in lycopene and phenolics (Abid et al., 2017), walnut kernel septum membranes extract (Mehdizadeh et al., 2019), pure lycopene, turmeric extract and red beetroot extract powder (Asadaii et al., 2020) have also been employed.

Contrary to other dairy products and due to the role of butter (mainly as a spread for bread), fruits, fruit seed extracts, vegetables, are not used in its production. However, numerous scientific reports have proposed the possibility of adding fruits (juice, pulp, puree) to dairy products, e.g. fermented milk (Chouchouli et al., 2013;Oliveira et al., 2015). The addition of bioactive phytochemicals, enzymes, and antioxidants, change the typical features in terms of sensory and functional properties. Combination of dairy products and fruits can improve nutritional and functional food characteristics, at the same time on the shelf life and consumer acceptance (Salwa et al., 2004;Fazilah et al., 2018;Stinco et al., 2019). This is a trend driven by consumer acceptance of such products. Consumers appreciate the importance of innovative dairy products from bioactive phytochemicals also due to the natural flavouring and giving a specific colour, which results, for example, from anthocyanins and carotenoids. In addition to traditional fruit juices or pulps from pear, apricot, peach, apple, plum, strawberry, raspberry, bilberries, blackberry, blackcurrant and cherry (Coisson et al., 2005), are used even those little known, and wildly growing (Costa et al., 2017;Sigdel et al., 2018;Van Nieuwenhove et al., 2019). As a functional ingredient for food, researchers have investigated Euterpe oleracea juice, elderberry (Sambucus nigra L.), sloe berry (Prunus spinosa L.), Camu-camu (Myrciaria dubia), and seed extract sea buckthorn (Hippophae rhamnoides) (Coisson et al., 2005;Młynarczyk et al., 2018;Terpou et al., 2019;Urkek et al., 2019;Fidelis et al., 2020).

As can be seen from a literature review by Olas (2016), sea buckthorn (Hippophae rhamnoides L.) has significant cardio-protective activity, inhibits blood platelet activation (especially platelet aggregation), lowers cholesterol concentration and blood pressure, and provides antioxidant activity. Sea buckthorn has also antiviral and antibacterial properties. The leaves and fruits of the plant are sources of many bioactive substances including vitamins (A, C and E), unsaturated fatty acids, phenolic compounds, especially flavonoids, and phytosterols.

Due to the health-promoting value of sea buckthorn and its colour resulting from the presence of carotenoids, it is warranted to examine its possible application in goat cream butter. Goat butter was selected because it is whiter than cow butter (Lee, 2020). The colour of goat butter is not so yellow, therefore, enhancement of the butter’s colour may be a good solution from a consumer point of view.O’Callaghan et al. (2018) reported that butter with more carotenoids received significantly greater scores in sensory analysis. Furthermore,Krause et al. (2007) indicated that health, flavour and spreadability play an important role in decision making regarding the purchase of butter (39%, 48% and 17%, respectively). Additionally, the disadvantage of unsatisfactory spreadability of goat butter at low temperatures has been considered (Queirós et al., 2016). Hence, we proposed an investigation into whether the addition of puree sea buckthorn during the production of butter could change its texture parameters, such as consistency, firmness, and spreadability. At the same time, we assessed consumer acceptance, if such properties coincide with consumers’ expectations of novel butter with new functional and sensory properties.

Materials and methods

Sample preparation

Butter. Raw milk from white polish goats from region in west-central Poland was received at laboratory facility, filtered, preheated (40 °C) and skimmed using electric separator MILKY FJ 90PP (Franz Janschitz GmbH, Althofen, Austria) producing cream with 35% minimum fat content. The obtained cream was pasteurized using a pasteurizer MILKY FJ 15 (Franz Janschitz GmbH, Althofen, Austria) at 65 °C for 30 min and then cooled to 11 °C. Churning was conducted immediately in butter churn MILKY FJ 10 (Franz Janschitz GmbH, Althofen, Austria), which continued until butter particles were formed. Butter particles were washed three times with cold water (1-2 °C). 1.5% and 3.0% w/w of pasteurized sea buckthorn puree (EkaMedica, Kozy, Poland) was added to the butter (sample code BP1 and BP2). The obtained butter was worked out in the churn until water and puree were evenly distributed. Butter was divided into equal portions (250 g each) in prepared blocks of 100 mm x 75 mm x 30 mm. It was packaged in polystyrene bags. A control sample (sample code BC) without the addition of pulp was produced in an analogous manner. Butter samples were stored at 3±0.5 °C.

Experimental design. The production process of butter was carried out in pilot plant scale (n = 9). Samples were tested 48 h after the end of the production process.

Compositional and physicochemical analysis

Composition. The content of water, protein, fat and other ingredients in milk and cream were measured with calibrated DairySpecFT, respectively (Bentley Instruments Inc., Chaska, MN, USA). The device was used for the current monitoring of milk’s composition (ISO 9622, 2013;Senevirathne et al., 2019). Ascorbic acid content was determined using the method described byCappato et al. (2018) using 2,6-dichlorophenol-indophenol. For the extraction process, 5 mL of sample was mixed with 25 mL of metaphosphoric acid solution. The content of macroelements was determined using an SP-2900 atomic absorption spectrophotometer (Pye Unicam Ltd., Cambridge, UK) with background correction and flame system, using appropriate cathode lamps and dry mineralization of samples at temperatures up to 450 °C. Fat, protein, moisture, and ash content in butter was determined according to the methods described by Lee et al. (2020). Total carotenoid was determined according to the method described by Aaby et al. (2020).

Acidity. The pH was measured using a CP-502 pH-meter (Elmetron, Zabrze, Poland) equipped with a combination electrode ESAgP-301W (Eurosensor, Gliwice, Poland) composed of glass and saturated silver chloride half-cells. The titratable acidity values expressed as Soxhlet-Henkel degree (°SH, 1°SH=0.0225 lactic acid %).

Freezing point. The freezing point of the studied milk was determined according to ISO 5764 (2009) standard method using an Advanced® Model 4D3 cryoscope with 3LH700 thermistor probe (Advanced Instruments Inc., Norwood, Massachusetts, USA).

Water Activity. The water activity was measured with an AquaLab Series 4TE instrument (Decagon Devices Inc., Pullman, WA, USA). The measurements were carried out under conditions of thermodynamic equilibrium. The following salt solutions were used for reference: 0.5 M KCl about aw = 0.984 (15 °C), 6 M NaCl of aw = 0.760 (20 °C), 8.57 M LiCl of aw = 0.500 (25 °C) and 13.41 M LiCl of aw = 0.250 (25 °C). Samples of v = 15 mL were placed in a DE 501 measurement vessel (Decagon Devices Inc., Pullman, WA, USA) and tested at 15 °C.

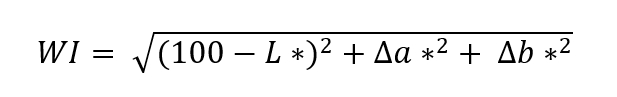

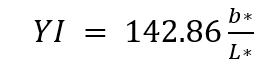

Colour Measurement. A milk and butter sample was placed in an OG cuvette 2/96G/10 (Starna Scientific Company Ltd, Ilford, UK). The measurement was performed with a D65 light source, and 10° observation angle using an X-Rite SP-60 camera (Grandville, MI, USA). The camera was calibrated based on the black and white SP-62-162 reference standards (Grandville, MI, USA). Sample measured specular included (SPIN). The colour was analysed on the basis of L* indicating lightness 100 = white, 0 = black, a* values representing -green/+red and b* values representing −blue/+yellow (Cais-Sokolińska et al., 2018). The whiteness index (WI) was calculated using Eq. [1] and yellowing index (YI) using Eq [2]. The calculations assumed the following: ideal white L* = 100, a* = 0, and b* = 0.

Profile Texture Analyses. Texture parameters were measured using a TA-TX.plus texture meter (Stable Micro Systems, Surrey, UK). The following attachments were used: A/BC (cutting force), P/25 (firmness, work of penetration, resistance to probe withdrawal), HDP/SR (firmness, work of shear). Butter samples were prepared in accordance with recommendations from the apparatus manufacturer. Measurement conditions depended on attachment type used: A/BC attachment (Test Speed 0.5 mm·s-1, Pre-Test Speed 1.0 mm·s-1, Post-Test Speed 10.0 mm·s-1, distance 25.0 mm), P/25 attachment (Test Speed 2.0 mm·s-1, Pre-Test Speed 1.0 mm·s-1, Post-Test Speed 2.0 mm·s-1, distance 12.0 mm) and HDP/SR attachment (Test Speed 3.0 mm·s-1, Post-Test Speed 10.0 mm·s-1, distance 23.0 mm). Results were recorded in Texture Exponent E32 version 4.0.9.0 software (Godalming, Surrey, UK). The cut was made on a wall of butter 100 mm wide at 10 °C.

Sensory analysis

Descriptive sensory analysis. Sensory analysis was conducted using the profiling method. Panel members (n = 9; 6 female, 3 male; ages 26 to 64; Mage = 47, SD = 12.9) were adequately trained individuals, prepared to perform sensory examinations. The panel received about 27 h of training. During the training sessions, potential references were presented to the panellists to identify descriptors. After the training phase, samples were evaluated using 9 cm unstructured line scales anchored with the terms low (denoting an undetectable point parameter) at the left and high (very intense) at the right. The assessors evaluated two samples in each session, evaluating two replications of each sample. Each time 7 g of butter was evaluated at a temperature of 15-18 °C. Panellists evaluated 6 samples per session and were given room-temperature water and unsalted crackers (Krause et al., 2008). The descriptors are shown inTable 1.

Acceptability. In the sensory test, consumers (n = 105; 64 female, 41 male; ages 23 to 61; Mage 34, SD = 8.3) were asked to indicate how much they liked or disliked each product on a 9-point hedonic scale (9 = like extremely; 1 = dislike extremely). Consumers were randomly recruited based on non-allergic reactions to milk and regular consumption (at least once a week) of butter (Karnopp et al., 2017). Samples of 7 g (10-12 °C) were served on plain bread.

Investigation of consumer perception

Consumer Penalty Analysis. For this purpose, the methodology described byCosta et al. (2017) was used. Evaluation was conducted using a 5-point just-about-right (JAR) scale anchored at both extremes (1 = not enough to 5 = too much), with a central point at 3 (3 = ideal): flavour (acidity), aroma (buttery, fruit and animal), colour (white and orange), and texture (consistency and stickiness). Test participants are consumers who consume dairy products (n = 105; 64 female, 41 male; ages 23 to 61; Mage 34, SD = 8.3).

Statistical evaluation

For the verification of statistical hypotheses, a level of significance of α = 0.05 was adopted. The influence of composition on the samples was evaluated by two-way analysis of variance (one-way ANOVA) followed by Tukey’s HSD post hoc test for multiple comparisons. The skewness, which is a measure of asymmetry, was used to assess normality distribution. In order to determine the position of the tested samples in the perception of the sample space, the results were evaluated using Principal Component Analysis (PCA) based on the NIPALS algorithm. The data were analysed using Statistica data analysis software, version 13 (TIBCO Software Inc., Palo Alto, California, USA).

Results and discussion

The composition and technological properties of goat’s milk and sea buckthorn puree are listed inTable 2, whereas texture of cream and sea buckthorn puree are listed inTable 3. Model sample of goat butter was characterized by fat (81.2%) and moisture (14.8%) content, which met the standard requirement of butter (USDA, 1989). Additionally, the butter contained 0.96% proteins and 1.17% ash. According toLee (2020), goat’s milk cream compared to that cream from cow’s milk has lower melting point due to higher proportions of short- and medium-chain fatty acids such as caproic (C6: 0), caprylic (C8: 0), and capric (C10: 0) acids, which account for approx. 15-18% of all fatty acids in goat’s milk (Clark and Garcia, 2017). They are mainly responsible for the characteristic texture of butter (Lee, 2020).

a-bMeans within a row with different superscripts differ (P<0.05). SEM: standard error of the mean (n = 9)

1Parameters: TN = total nitrogen; NPN = nonprotein nitrogen; NCN = noncasein nitrogen; TP = total protein (TN-NPN)×6.38; C = casein (TN−NCN−NPN)×6.38; WP = whey protein (NCN−NPN)×6.38; CGA = chlorogenic acid; C3G = cyanidin-3-glucoside; L* = lightness; a* = -green/+red color; b* = -blue/+yellow; WI = whiteness index; YI = yellowing index; nd = non detected

| goat`s cream | sea buckthorn puree | SEM | |

|---|---|---|---|

| Firmness (g) | 15.13a | 28.23b | 1.88 |

| Consistency (g∙s) | 308.69a | 666.40b | 0.62 |

| Cohesiveness (|g|) | 10.55a | 21.59b | 0.28 |

| Viscosity index (|g∙s|) | 6.14a | 40.58b | 0.34 |

a-bMeans within a row with different superscripts differ (P<0.05). SEM: standard error of the mean (n = 9)

The addition of sea buckthorn puree influences the texture of butter (P<0.05,Table 4). As the amount of sea buckthorn puree added increases, the butter becomes softer and more spreadable. The work of shear measured using the spreadability attachment HDP/SR is larger in the control butter (15269 g∙s), and smallest in goat cream butter with 3% sea buckthorn puree (8532 g∙s). Firmness of the sample BP2 is 1.8 times smaller than the control butter. Firmness of the sample BP2, measured using the cylinder probe, is also the smallest of all tested samples (P<0.05).Rashevska and Vasheka (2011) examined the consistency and changes occurring in the fatty phase of butter with carrot powders, where the enriched butter displayed better hardness and plasticity. The melting curves of butter showed that the introduction of carrot powder promoted a displacement of fusible glycerides of the solidification front into the zone of lower temperatures.Rashevska and Vasheka (2011) was examined the phase transformation in butter fat using differential scanning calorimetry methods.

a-cMeans within a column with different superscripts differ (P<0.05). SEM: standard error of the mean (n = 9).

Samples: BC = butter control; BP1 = butter with 1.5% sea buckthorn puree; BP2 = butter with 3% sea buckthorn puree.

Through comparison of the colour parameters of cream and butter, it suggests that the colour change is affected by the concentration of fat and removal of colour compounds with buttermilk (Table 5).

| Parameters | C | BC | BP1 | BP2 | SEM |

|---|---|---|---|---|---|

| L* | 77.13b | 82.23c | 76.77b | 74.66a | 0.44 |

| a* | 0.19a | 1.54c | 0.79b | 1.57c | 0.01 |

| b* | 4.51a | 5.72b | 16.25c | 19.50d | 0.12 |

| WI | 23.31b | 18.73a | 28.39c | 32.02d | 0.36 |

| YI | 8.36a | 9.94b | 30.26c | 37.33d | 0.51 |

a-dMeans within a column with different superscripts differ (P<0.05). SEM: standard error of the mean (n = 9)

Samples: C = cream; BC = butter control; BP1 = butter with 1.5% sea buckthorn puree; BP2 = butter with 3% sea buckthorn puree

Parameters: L* = lightness; a* = -green/+red colour; b*: -blue/+yellow; WI = whiteness index; YI = yellowing index

The colour of buttermilk is slightly beige, and its coordinates are as follows: L* = 64.63, a* = 0.24, b* = 4.97, and calculated WI = 35.72 and YI = 10.98. The colour of goat butter differs significantly from the standard for which the colour of cow’s or buffalo’s milk butter was adopted. The natural lack of carotene in goat butter made L* colour coordinate closest to the maximum value (L* = 82.23), and yellow coordinate (b* = 5.72) closer to zero. In the colour of sea buckthorn, L* coordinate is characterized by a low value (L* = 36.51), while b* coordinate is high (b* = 27.61). Addition of sea buckthorn puree to butter significantly changes its colour (Table 5). The butter has a typical yellow colour. The colour of goat’s milk products shows high brightness (L*) values with a predominance of b* coordinate over a* coordinate. These values are related to the more intense white colour, most likely due to the smaller diameter of the fat globules in goat’s milk (3.5 μm in goat’s milk compared to 4.5 μm in cow's milk) and complete conversion of β-carotene to vitamin A, which occurs in the metabolism of goats (Lucas et al., 2008). That colour is a very characteristic feature of goat’s milk according toVerruck et al. (2019). L* value depends on the dispersion of casein micelles and fat globules that affect the diffusion of incident light (Nozière et al., 2006).O’Callaghan et al. (2018) showed that butter with more carotenoids received significantly greater scores in sensory analysis. Research on potential production of value-added butter with enhanced nutritional and microbiological properties was conducted byThakaeng et al. (2020). These studies show that green tea extract can be used as a natural food additive, antioxidant, and preservative in butter but can cause significant colour changes. This is related to reduction in lightness and yellowness, which in turn negatively impacts sensory acceptance. The incorporation of up to 6% (w/w) green tea extract did not compromise the sensory acceptance of the butter produced.Thakaeng et al. (2020) considered the powder form of green tea extract instead of liquid form in the future, which allows the redness (a* value) to be blocked by the brown colour of green tea extract. In our research large interference of a* parameter on the acceptability of sea buckthorn butter is not observed.

All defined flavour and aroma had a decisive influence on the differentiation of butter samples. The values of the taste and odour of butter are presented in the form of multidimensional profiles using the exploratory technique (Figure 1). The most noticeable parameters in control butter are milk fat (6.3 score), country (7.0 score) and waxy/animal (9.2 score). After addition of sea buckthorn puree, the perceptibility of these aromas decrease significantly (P<0.05), and a more noticeable acidic flavour and aroma: fruity, grassy, are observed. The biggest difference is noted in the acidic flavour from 4.2 score (BP1) to 6.0 score (BP2).

From left to right: BC = butter control; BP1 = butter with 1.5% sea buckthorn puree; BP2 = butter with 3% sea buckthorn puree

Generally, all variables involved in the analysis are reduced to one dimension (∑ 98.63%,Figure 2). The first major axis is crucial to explaining the overall variability of the data (P:81.56%). This confirms the different flavour and aroma profile, appearance, texture and mouthfeel of goat cream butter with sea buckthorn puree compared to the control butter. The almost white (1.5 score) BC butter after addition of 1.5% and 3% sea buckthorn becomes very orange (5.5 and 6.7 score, respectively, P<0.05). The addition of sea buckthorn (P>0.05) reduces hardness (from 9.8 to 8.4 score) and increases spreadability, but only at the amount of 3% puree (from 5.4 in BC to 6.3 score in BP2).

The opinion of consumers strongly differentiates between sensory acceptance of butter with sea buckthorn puree and control butter (Table 6). In general, responses after addition of sea buckthorn to butter in the amount of 1.5% (BP1) increases 1.7 times more, whereas after addition of 3% (BP2) decreases by as much as 2 times. It is shown that after addition of sea buckthorn to butter, there are fewer undecided consumers (neither like nor dislike), decreasing from 48% (BC) to 12% (BP1) and 11% (BP2). This analysis shows that butter with 1.5% sea buckthorn has the highest acceptability, and dislike responses in this case is only 5.71%. The preference mapping of butter described byKrause et al. (2007) to identify drivers of liking shows that key butter features to consumers include desirable flavour and natural image.

SD = standard deviation; CV = coefficient of variation

BC = butter control; BP1 = butter with 1.5% sea buckthorn puree; BP2 = butter with 3% sea buckthorn puree

The consumer penalty analysis identified features that caused low or high acceptability (Table 7). Consumers (64.8%) state that goat cream butter with 3% sea buckthorn puree is definitely too acidic. Almost half of consumers reported the lacked of animal aroma in BP1 and BP2. However, a quarter of the consumers declared with goat butter samples without sea buckthorn there is excessive animal aroma. Half of the consumers perceived neither control butter nor butter with sea buckthorn as typical butter. Presumably it is related to the colour. The more sea buckthorn added, the butter becomes more orange according to the consumers (1.5% added - 10.5% of consumers, and 3% added - 67.6% of consumers). In terms of consistency, each of the samples is almost perfect. Additionally, sea buckthorn improves the butter stickiness. It is very important to take into account all properties of goat’s milk products, and above all their sensory values in terms of consumer expectations of these products (Verruck et al., 2019). This may favour devise strategies to develop the sector (Pinto et al., 2018).

(-) = indicates that less than 10% of consumers chose that JAR category

BC = butter control; BP1 = butter with 1.5% sea buckthorn puree; BP2 = butter with 3% sea buckthorn puree

Conclusion

Goat butter is a very distinctive product due to its animal aroma, texture (firmness and spreadability) and colour. It is almost white, which is confirmed by the small whiteness and yellowing index values. Less than half of consumers accept goat butter on a sensory basis. Butter with 1.5% sea buckthorn is definitely more acceptable to consumers than goat butter without sea buckthorn, which is ideal in terms of animal aroma and consistency. It has better texture (stickiness) and acidic flavour than goat butter. The number of consumers who like goat butter increases by as much as 35% after addition of 1.5% sea buckthorn. Further increasing the amount of sea buckthorn to 3% makes the butter unacceptable due to excessive acidic flavour, fruit aroma, orange colour, and not enough buttery taste and odour. Based on these results, it can be concluded that the model butter has good physiochemical and sensory properties. Therefore, this research clearly shows that sea buckthorn puree can be successfully incorporated as an ingredient with natural colouring properties.

The combination of goat butter with sea buckthorn can set a new direction in modern cream processing. Butter, which has the added value by incorporation of fruit puree can meet consumer demand. They can be part of an improved and healthy diet. At the same time, such a combination can lead to a better and more attractive use of goat’s milk products. Thus, the number of consumers of goat milk products may increase.