INTRODUCTION

UVOD

Public awareness of occupational safety and health issues has increased and the need to protect workers in the workplace has become increasingly important with the advancement of science and technology in recent years. However, legal regulations have been established to identify hazards arising from work, working environments, or workers in all sectors and implement the relevant measures to address them. At the international level, the European Union (EU) Directive 89/391/EEC on OSH Framework and the International Labor Organization (ILO) conventions (Articles 155 and 161), as well as Labor Law of Türkiye (Act No. 4857), have placed the responsibility on employers to carry out risk assessments in the workplace (Council of The European Communities, 1989; Labor Law of Türkiye, 2003). The EU directive states that each state may develop a specific risk assessment methodology through its legislation (Ristic, 2013; Stankovıć and Stankovıć, 2013). The legal obligations and the growing interest of the public have necessitated risk analysis in all sectors and the implementation of necessary measurements to minimize damage (Haimes, 2009).

Risk assessment is an essential tool to ensure occupational safety in all sectors (Marhavilas and Koulouriotis, 2008). Risk analysis, the second step of risk assessment, can be simply described as the investigation of the probability and severity of each sub-risk (Cruze Netro et al., 2018; Workcover NSW, 2002). Risk analysis is performed to understand the nature, sources, and causes of the identified risks and to predict risk levels (ISO, 2018). Risk analysis is a key indicator because it provides preliminary information regarding workplaces and facilitates the implementation of safety measures. It is also vital to the national economy, as it positively impacts productivity and the quality of production, as well as better compliance with the regulations.

Risk analysis is applied to determine whether the risk level can be acceptable for examined processes. There are many risk analysis methods such as Fine-Kinney, risk matrix, event tree analysis (ETA), failure mode and effects analysis (FMEA), and fault tree analysis (FTA) (IEC, 2019; Fedorets, 2022; Khan et al., 2015; Ruijters and Stoelinga, 2015). The risk matrix method, one of the semi-quantitative risk analysis methods, is a popular and practical decisionsupport tool due to its ease of understanding and use. Furthermore, the method is widely used in various industry sectors by standardizing the risk assessment process (Kerckhoffs,2017; Monat and Doremus 2018;Sutherland 2022; World Economic Forum,2021). The method, which measures and classifies risk based on conscious judgment, has gained significance because of documented pitfalls and attention to negative outcomes (Albery et al., 2016; Duan et al., 2016; Duijm, 2015; Pascarella et al., 2021; Reniers et al., 2009). It shows how both elements contribute to overall risk by providing a visualization for both the probability of an event and the impact of the event (Pascarella et al., 2021; Van der Felsklerx et al., 2018).

One of the most dangerous activities in forestry is forest harvesting. Harvesting activities were categorized into the “hazardous work” class in the Communique of Hazard Classes Regarding OSH (Nieuwenhuis and Lyons, 2002; WHC, 2012). These activities differ from other sectors because they are land-dependent, labor-intensive, constantly changing, directly exposed to different climatic parameters (e.g. rainfall, temperature, wind), include poor working conditions, mess environment, limited deadlines and make workers vulnerable to external hazards (e.g. wild animals, insects, poisonous plants and rockfalls) (Unver 2013). Globally, the number of workers employed by the forestry industry is approximately 33 million, which corresponds to approximately 1.0% of the overall global labor force (ILO, 2022). Between four and ten of these workers face severe accidents annually because of significant risks resulting from various factors in forestry activities (URL-1, 2023). In Türkiye, due to economic constraints and a lack of trained personnel, the development of mechanization in forestry is limited, making fully mechanized harvest systems almost non-existent. Felling activities are carried out with chainsaws, and extraction activities are largely carried out by employing ground-based skidding. Agricultural and forestry tractors are mostly used for skidding, and there is also limited use of skylines and skidders.

Vianna et al. (2008) found that the primary causes of workplace accidents in the forestry sector were unsafe actions (50.71%), hazardous conditions (16.98%), and individual factors related to safety (17.94%). The functional assessment revealed that 7.14% of the accidents involved workers performing tasks outside of their established job descriptions as per their employment contracts. Sant'Anna and Malinovski (2015) determined that chainsaw operators were exposed to accidents at a rate of 44.8% and suffered significant back pain. Therefore, it is recommended to take preventive measures, develop training strategies, and change the operational system to prevent back pain.

The data used in risk analysis can be generally obtained from Social Security Council records, reports of work accidents, workplace measurements, annual reports published by the General Directorate of OSH, Statistical Institute records, and accident reports at similar workplaces. According to the Forest Law in Türkiye, forest harvesting activities are contracted out to villagers living in the nearest forest village, contractors, or the forest villagers’ development cooperatives (The Forest Law, 1956). Therefore, forest harvesting is carried out by seasonal workers who have no training in forest harvesting or OSH, and no health insurance for harvesting work. This is an obstacle to the creation of a database of work accidents, occupational diseases, nearmiss accidents, injuries, and deaths suffered by these workers. This lack of data complicates risk analysis by estimating values such as the frequency and severity of forest harvesting. Moreover, the results of some studies have suggested that knowledgeable and experienced experts should conduct risk analyses based on the experiences of employers or workers in the industry if reliable data are missing (URL-2, 2023; Wesdock and Arnold, 2014). Otherwise, risk levels for hazards are calculated incorrectly and priorities may be incorrectly achieved.

Throughout the world, risk analysis studies have generally been conducted for specific tree species in a single geographical region or for some stage of the forest harvesting process (Grassi et al., 2009; Gülci et al., 2016; Hu et al., 2009; Kang et al., 2014; Reniers et al., 2009; Sayın et al., 2014; Unver-Okan et al., 2017). Risk analysis for forest harvesting activities cannot be standardized due to varying workplace conditions, different tools and machines used, and the properties of the worker. Therefore, separate risk analyses of harvesting activities in different geographical regions can provide more reliable results. For this purpose, in this study risk analyses were performed using the matrix method for forest harvesting activities in five geographical regions of Türkiye with distinctive characteristics, after which the risk scores were compared.

MATERIALS AND METHODS

MATERIJALI I METODE

Study area – Područje istraživanja

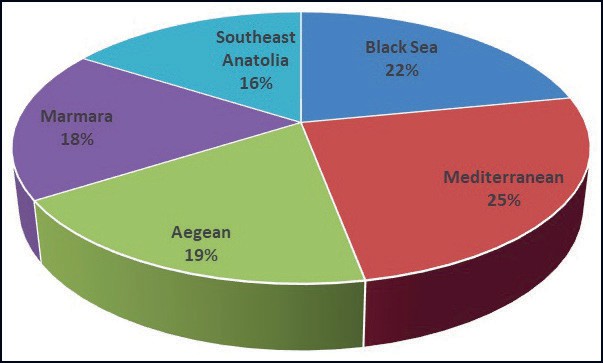

The study was conducted in five geographical regions of Türkiye: Black Sea, Mediterranean, Aegean, Marmara, and Southeast Anatolia, with different climatic, topographic, and forest conditions (Figure 1).

The Black Sea region includes more than 75% of Türkiye's forests and has a steep topography. The Black Sea has high and evenly distributed rainfall throughout the year. Summers are warm and humid, and winters are cool and damp along the coast. The Mediterranean is a mountainous region where the mountains run parallel to the sea, and the mountains meet the sea in most places except the plains. Summers are hot and dry, and winters are warm and wet.

Figure 1 Study areas

Slika 1. Područja istraživanja

The Marmara region is not overly mountainous and has an east-west elevation with north-south oriented valleys separated from each other. The region has a hybrid Mediterranean climate on the Aegean and South Marmara coasts, an oceanic climate on the Black Sea coast, and a humid continental climate in the interior. Summers are warm to hot, humid, and moderately dry, while winters are cold and wet. In the Aegean region, the mountains run perpendicular to the sea and are arranged as a mountain range and a plain from north to south. It has a Mediterranean climate on the coast, with hot, dry summers; and mild to cool, wet winters. The interior has a semi-arid continental climate, with hot, dry summers and cold, snowy winters. Southeastern Anatolia is at a higher elevation than the rest of Türkiye, with an average elevation of 2,200 m. It has a semi-arid continental climate with very hot, dry summers and cold, often snowy winters.

Target group – Ciljna skupina

This study was conducted through face-to-face interviews with a total of 338 forest harvesting workers from five regions. The distribution of the respondents in the study areas is shown in Figure 2.

The majority of participants in this study were chainsaw operators and manpower-skidding workers. The workers in the target group, who were all male, ranged in age from 23 to 62 years and had at least 8 years of experience in forest harvesting. Percentage distribution of participants by age classes was as follows: 15-25 years old (13.33%), 26-35 years old (25.71%), 35-45 years old (26.67%), 45 years and above (34.29%). The majority of the participants are primary school graduates (75.16%), followed by high school graduates (13.06%), literates (6.69%), illiterate people (3.82%), and a very small percentage of university graduates (1.25%). The majority of individuals are married (79.37%), a smaller portion are single (19.68%), and a tiny percentage are widowed (0.95%). Participants generally worked in felling (73.27%), manual skidding (63.21%), skidding by animal power (21.70%), extracting by forest tractors (43.40%), and operator (20.44%) works. In addition, these workers had no training in OSH. The interviews with the workers were conducted by two forest engineers and one academic.

Step 1: Identify hazards

Korak 1: Prepoznavanje opasnosti

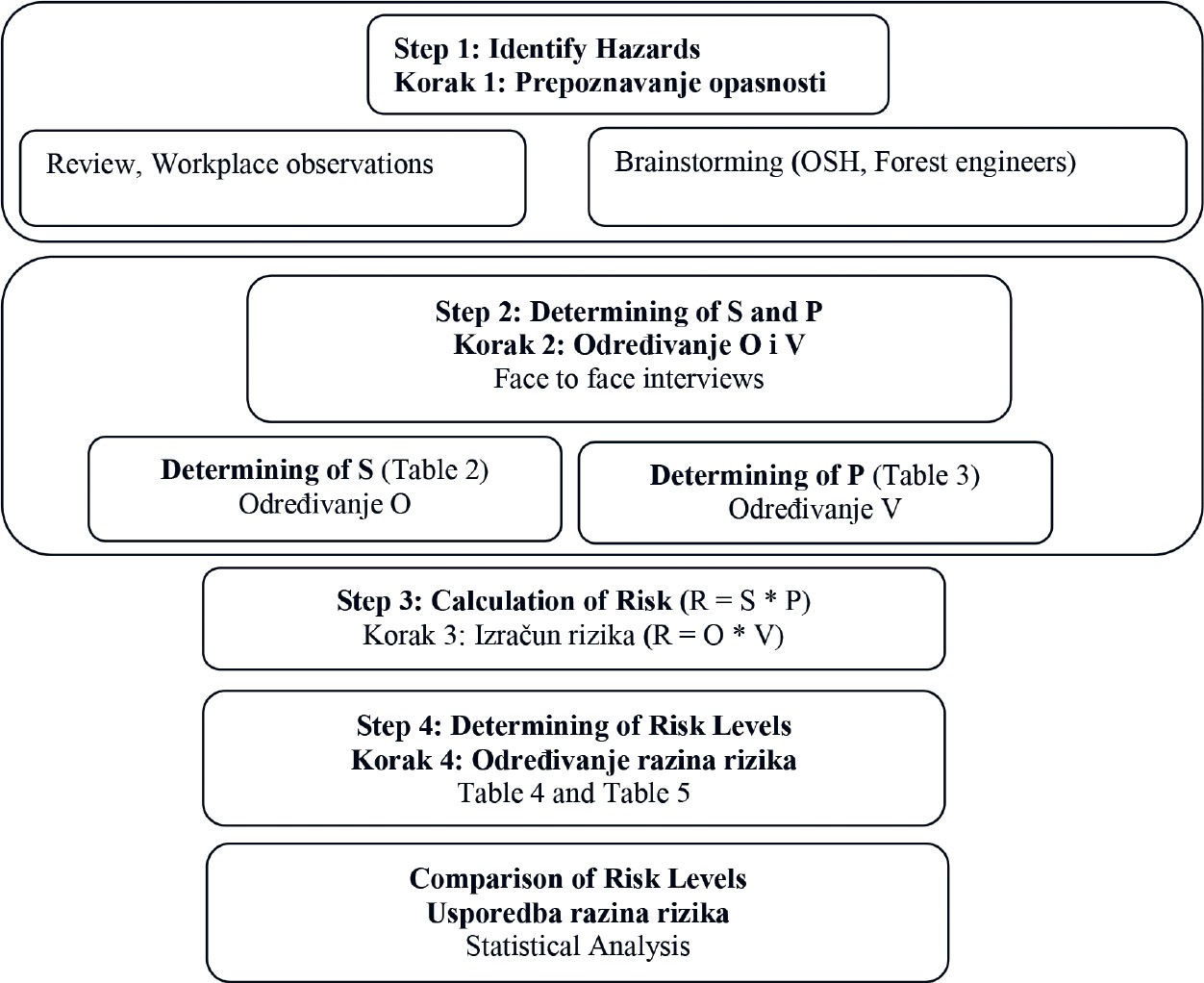

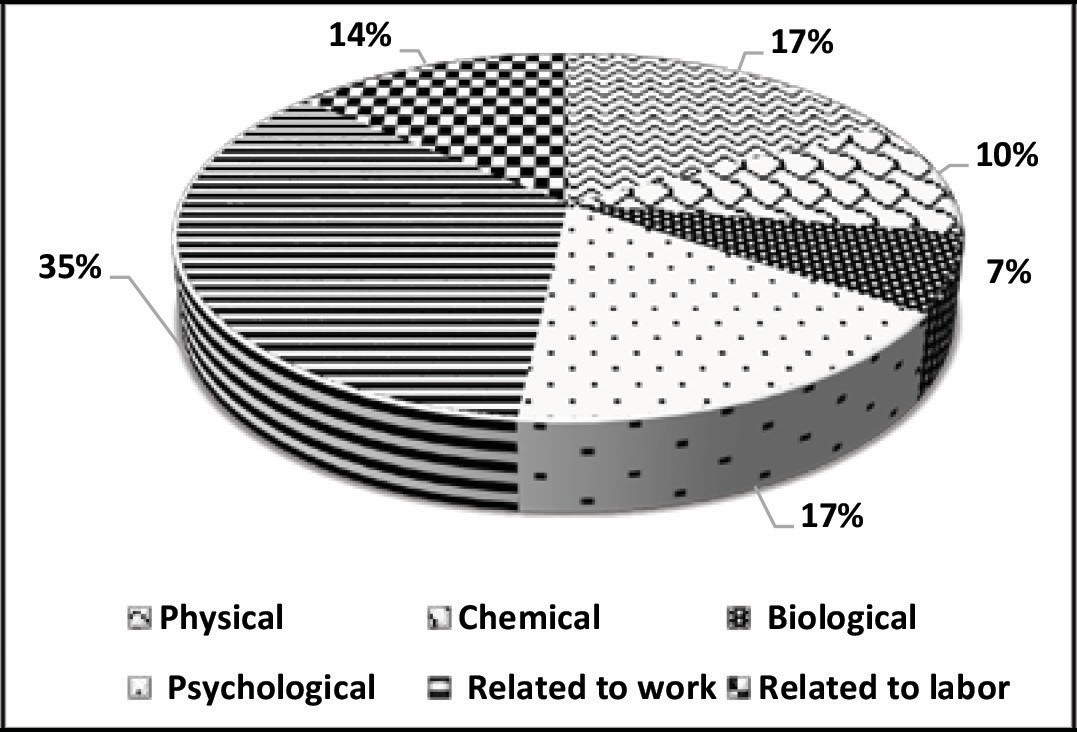

Successful implementation of the risk matrix method depends on a clear definition of possible hazards and a correct representation of probability and severity (Talbot, 2017). Data on the potential occupational hazards of forest harvesting were obtained by reviewing previous risk analysis studies (Gokbayrak, 2005; Pinto et al., 2011; Poschen, 1998; Tixier et al., 2002) and by field observations in harvesting units. The collected data was evaluated through brainstorming by five employers, three OSH experts, and two academics. As a result of the research, 29 sub-risk factors were grouped into six main risk factors: physical (5), chemical (3), biological (2), psychological (5), workrelated (10) and worker-related (4) hazards (Table 1). The proportional distribution of the sub-risks to main-risk classes was specified (Figure 4).

Table 1 Possible hazards for harvesting activities.

Tablica 1. Moguće opasnosti kod sječe

Step 2: Determining the probability and the severity of hazards

Korak 2: Određivanje vjerojatnosti i ozbiljnosti opasnosti

The method aims to determine how to assess the probability of a hazardous event and the severity of the event if it occurs. In this method, the risk matrix method was used as a guideline for the severity rating (Table 2), and as a guideline for the probability rating (Table 3) (WSH, 2015).

Step 4: Determining risk levels

Korak 4: Određivanje razina rizika

Acceptability levels for the calculated risk scores were interpreted using the risk assessment decision matrix table (Table 4).

Table 2 A guideline to severity rating

Tablica 2. Smjernica za ocjenu ozbiljnosti

Table 4 The risk-assessment decision matrix (WSH, 2015)

Tablica 4. Matrica odlučivanja o procjeni rizika

Table 5 Action plan for risk matrix method (WSH, 2015)

Tablica 5. Akcijski plan za metodu matrice rizika (WSH, 2015.)

Statistical Analysis – Statistička analiza

The probability (P) and severity (S) data were analyzed using the SPSS 16.0 package program. The reliability of the P and S parameters obtained in the risk analysis was tested using reliability analysis. Frequency tables were created for the variables analyzed, and cross tables were created to examine dependent and independent variables. The chi-square test was used to determine whether the risk scores varied according to different regions.

Table 7 Risk scores for study areas

Tablica 7. Rezultati rizika za područja istraživanja

REZULTATI

Most of the hazards identified for harvesting workers in this study were in work-related (35%), physical (17%), and psychological (17%) risk groups as shown in Figure 4. Physical hazards can result from the dependence of forest harvesting on climate and topography. The implementation of harvesting techniques requires much attention at each stage of forest harvesting because the trees or timber are heavy and difficult to control. The psychological risks could arise from the fact that forests are located far from urban centers and that forest harvesting is temporary work.

The reliability level of the P and S values determined by personal judgment was tested by applying reliability analysis (Table 6).

As shown in Table 6, Cronbach’s alpha values for both P and S were calculated to be close to 1, indicating that the results were reliable. The risk score of each potential hazard for each region was calculated by using equation (1) and averaged (Table 7).

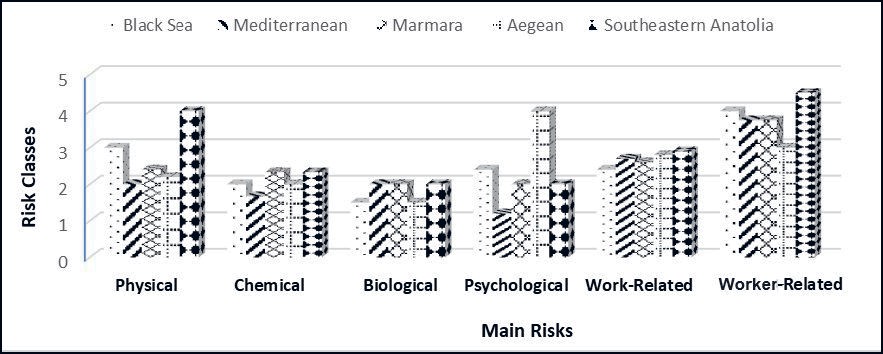

The regional distribution of the risk scores of the main risks was determined by taking the average of the sub-risks in each main risk class in Table 7 (Figure 5).

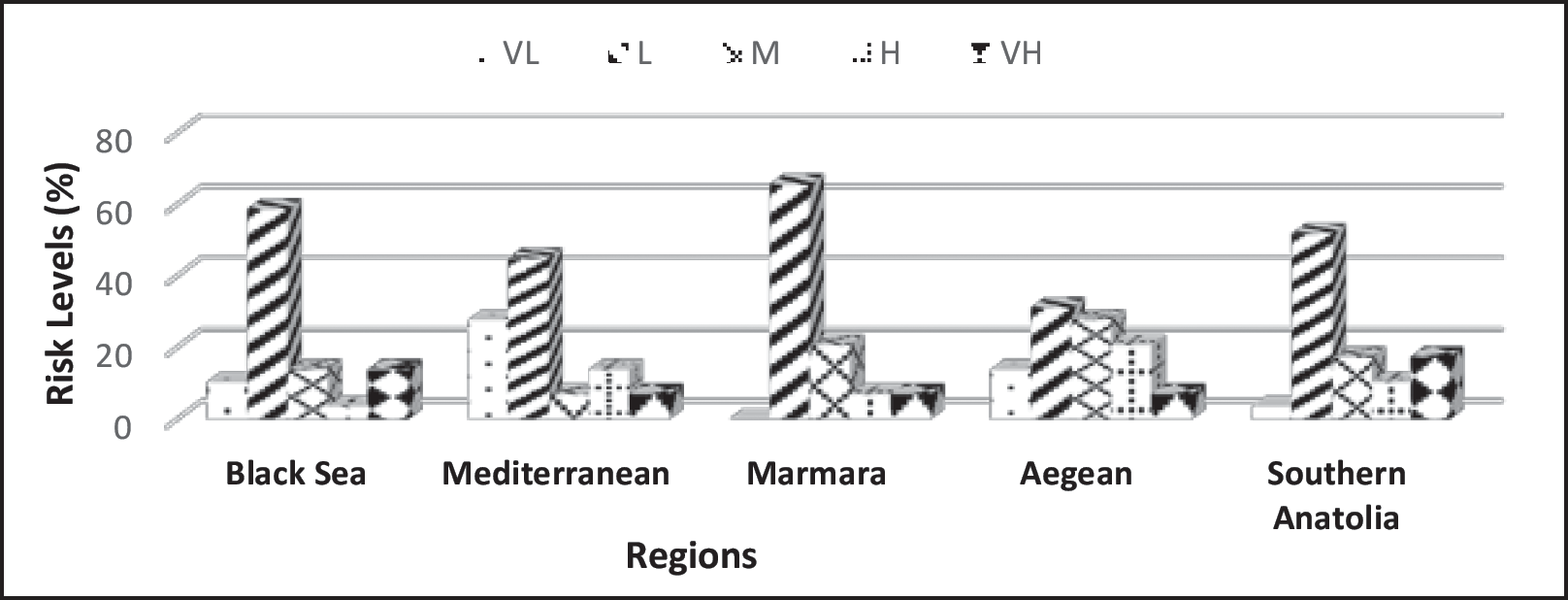

The distribution of hazards into risk classes for each region was determined by frequency analysis (Table 8), and distribution graphs were plotted (Figure 6).

As shown in Table 7, Table 8, and Figure 6, low (L) risk class was the most frequently observed in all regions. In addition, very-high (VH) risk class was observed in the Black Sea and Southeast Anatolian regions, very-low (VL) risk class was observed in the Mediterranean region, and moderate (M) risk class was observed in the Marmara and Aegean regions. The least observed risk classes in the Black Sea, Marmara, and Southeast Anatolian, Mediterranean, and Aegean regions were high (H), very-low (VL), moderate (M), and very-high (VH), respectively.

The Chi-square test was used to test whether there was a relationship between the risk classes and the regions (Table 9).

Figure 5 Distribution of main risks across regions

Slika 5. Distribucija glavnih rizika po regijama

Figure 6 Distribution of risk scores across regions

Slika 6. Distribucija ocjena rizika po regijama

Table 8 Frequency distribution of the risk grades

Tablica 8. Distribucija učestalosti stupnjeva rizika

RASPRAVA

The physical risks were generally observed with high (H) levels in the Southeast Anatolian and Black Sea regions and with very-low (VL) levels in the Mediterranean. This could be caused by the fact that the terrain in both Southeast Anatolian and Black Sea regions was rough and sloping. While it was observed that very cold was considered a risk in the Black Sea region, very hot was considered a risk in the Aegean and Mediterranean regions. In addition, both hot and cold were considered a risk in the Southeast Anatolian region. This situation could be due to the differences in the characteristics of climate between the regions.

Chemical risks were considered as low (L) risks in the Black Sea region, while smoke and hydrocarbons were considered as moderate (M) risks in the other regions. Similarly, Unver-Okan and Acar (2015) expressed that smoke or dust during forest harvesting could cause distraction, and loss of attention in the eyes of the operators, which could lead to occupational accidents. It was known that wood dust, which was responsible for almost 70% of occupational diseases (Tankut et al., 2014), could cause numerous diseases such as skin diseases, pneumoconiosis, and cancer (Salvendy 2012). The ignorance of pesticides and herbicides as a risk may have occurred because mechanical, biotechnical, or biological methods are preferred to chemical methods in pest control in Türkiye (GDF, 2016).

The levels of biological hazards were found to be very-low (VL) or low (L) in all regions. This may be because forest harvesting is carried out by forest villagers who are familiar with forest conditions and accustomed to living with wild animals and insects.

The levels of psychosocial hazards were also high (H) in the Aegean region, moderate (M) in the Black Sea region, and low (L) in the other regions. This may be because forest harvesting is carried out by workers who are familiar with forest conditions and accustomed to living with wild animals and insects. In the Black Sea region, a lack of occupational safety and being away from the social environment were identified as moderate (M) risk levels.

The levels of work-related risks were similar in all regions. The risk of collision with trees, rocks, or logs was high (H) in all regions. Heavy work materials, difficulty in steering vehicles and falling objects could cause severe accidents. Levels of risk in carrying and pushing were considered very-high (VH) in the Southeastern Anatolian region, high (H) in the Mediterranean region, and moderate (M) in the Aegean region. Similarly, it was found that pushing or carrying logs or fallen trees could lead to health problems such as fatigue, joint injuries, muscle or vertebral damage, a herniated disc, hernia, back and shoulder pain, and respiratory or circulatory problems in workers (Ketola et al., 2002). Poor working postures could be considered risky because they cause pain in the short term and musculoskeletal diseases in the long term (Gupta, 2016; IEA, 2023; Karwowski and Marra, 1990). In this study, harvesting workers often adopt poor working postures such as bending, squatting, and stretching during forest harvesting. The risk levels of poor working postures were found to be moderate (M) in the Marmara and Southeast Anatolian regions, as high (H) risk was observed in the other regions. Working in a messy environment in harvesting units was found to be a high (H) in the Mediterranean and Marmara regions, and a moderate (M) in the Aegean region. In harvesting units, all stages of forest harvesting such as cutting, pruning, peeling, and bucking are usually carried out simultaneously. Working in messy harvesting units could be considered risky because workers could be exposed to various accidents, such as falling and being struck by objects. In addition, the risk levels for vibration were low (L) in all regions. This could occur because the machines used by the workers are not very heavy, and the effects of vibration are observed only in the long term (Unver, 2013).

The risk levels of worker-related hazards were very-high (VH) in all regions. This could be raised by workers given physical or psychological unfitness for the work and lack of OSH training. This may have occurred because harvesting is mainly contracted out to forest villagers or outsourced, according to the Forest Law in Türkiye. The risk level of operator or driver error was moderate (M) in all regions, while the risk level of lack of protective equipment was very-high (VH) in the Southeast Anatolian region and moderate (M) in the Aegean region.

CONCLUSIONS

ZAKLJUČCI

In this study, the risk analysis of harvesting activities in five regions of Türkiye was performed using the risk matrix method. It was investigated whether the risk classes differ among the regions. The results of the risk analysis for forest harvesting showed regional differences with a 99% confidence interval. These differences were mainly observed in certain hazard classes, such as the physical condition of the working environment, and psychosocial and worker-related factors, while no differences were observed in biological or chemical hazard classes. The results also showed that lack of OSH training and workers unfit for work were considered unacceptable (VH) risks in all regions. In addition, collision with falling, rolling, or sliding objects was identified as an unacceptable risk (VH) in regions with rough topography. The lack of personal protective equipment was considered an unacceptable risk in regions with low education levels. Risk levels for psychosocial factors were high (H) in regions where forest harvesting was performed by nomadic workers living in camps in the forest. Risk levels for disconnection from the social environment and concerns about unemployment were moderate (M) in regions where alternative employment opportunities were limited. As forest harvesting was carried out by seasonal workers whose suitability for work was not assessed, the risk level of employing unfit workers was very-high (VH) in all regions. The levels for work-related hazards, such as poor working posture and collision with objects, were above moderate (M) in all regions. Risk levels for operator and driver error, which is a worker-related factor, were moderate (M) in all regions. The results of this study showed differences in risk analysis among different geographical regions. Therefore, it is recommended to take appropriate measures beforehand in regions where forest harvesting is carried out. In addition, conducting risk analyses of forest harvesting in regions with unique characteristics not examined in the current study could facilitate more realistic decision-making in the future. This study is important as it serves as an example for comparing risk analyses of other forestry activities.

Turkish forest law requires that forest harvesting work be employed by villagers residing in or near forest villages, without any formal forestry training. This situation may lead to workers neglecting potential risks such as unfamiliarity with the forest environment, topography, climate, wildlife, and harmful plants. In addition, workers may learn the job through observation and trial-and-error, and their awareness of work procedures, risks, and consequences of risks may be low. Since the understanding and implementation of basic safety measures by workers is limited, practices must be supervised by people trained in forestry and OSH. These professionals must also determine the necessary working standards and procedures, implement safety measures, and regularly inform employees about these risks, their possible consequences, and necessary precautions. Additionally, implementing a punishment/reward system could be useful to encourage compliance with security measures and increase general security awareness.