Introduction

Numerous authors have drawn a comparison between the effect of kombucha and the yoghurt starter culture, probiotics and kefir culture on the structure during milk fermentation and storage (Iličić et al., 2013; Malbaša et al., 2009; Vukić et al., 2014; Kanurić et al., 2018; Vukić et al., 2018; Carić et al., 2019). Many studies have aimed to analyse process fermentation, nutritive characteristics, rheological properties and sensory characteristics of kombucha fermented dairy products (Milanović et al., 2008; Kanurić et al., 2011; Vukić et al., 2014; Hrnjez et al., 2014; Ozyurt, 2020). While the time needed for kombucha fermented milk process to develop is 9 to 12 hours on average, the two times faster process was achieved with the use of probiotic cultures (Iličić et al., 2013). The chemical composition and sensory characteristics of kombucha fermented milk beverage differed significantly from yoghurt. Kombucha fermented milk product has specific nutritive and sensory characteristics, but it has weaker structure. Fortification of the milk base with some ingredients (skimmed milk powder, whey protein concentrates, whey protein isolate, inulin as fat replacer), as well as application of transglutaminase (TG) or some other functional components improved stability of fermented milk products. TG application is of utmost importance for fermented dairy products manufacture and quality.

Transglutaminase is a transferase that catalyses acyl transfer reaction between glutamine and lysine residues in proteins. The activity of this enzyme in milk depends on different factors such as the pH value, temperature, concentration of enzyme, milk composition and the applied technological process. Optimum range of pH and temperature for transglutaminase activity are 6-7 and 40-50 °C, respectively. It was found that during yoghurt fermentation 80% of the cross - linking effect was obtained at pH 6.6-5.7. Besides, the influence of the pH drop during fermentation on the reaction of TG, protein fortification as well as heat treatment of yoghurt milk play an important role in improving textural and rheological properties. UHT treatment of micellar casein suspended in milk improved significantly the cross-linking reaction (Bönisch et al., 2004, 2007; Carić et al., 2006).

The addition of TG to milk for the production of fermented milk contributed to an increase in gel strength and water holding capacity, decreasing at the same time whey syneresis. By increasing the concentration of TG, increased viscosity, texture, and a smoother surface could be observed. Set fermented TG-treated milk products produced with native kombucha showed significantly higher hysteresis loop area (1318Pa/s) than kombucha fermented milk without TG addition (418 Pa/s). Yield stress of kombucha fermented milk treated with TG (65.3 Pa) was significantly higher than in the control sample (1.14Pa). Ilicic et al. (2016) observed physical and rheological properties of fermented milk products obtained with native kombucha inoculum and the addition of TG and whey protein concentrate (WPC) under specific storage conditions. They found out that the structure of the stirred samples containing TG was more stable compared to the control sample - kombucha fermented milk product during the ten days storage. However, there are no data in recently published papers regarding the comparison of set and stirred kombucha fermented milk produced with addition of TG,.

This paper describes comparison of rheological and textural properties, and sensory characteristics of set new kombucha fermented milk products with addition of transglutaminase to stirred samples. The primary focus of this study were to investigate influence of concentrated kombucha inoculums and the addition of transglutaminase on chemical composition, textural and sensory properties, as well as rheological characteristics of fermented milk products.

Materials and methods

Kombucha fermented milk beverages manufacturing

Two series of set and stirred samples were manufactured: one from milk without TG and one from milk with TG. The TG of microbial origin obtained from Streptoverticillium mobaraense (producer Ajinomoto Company, Hamburg, Germany) was added in a concentration of 0.02 % (w/w). Kombucha inoculum (non-conventional starter culture) was prepared prior to milk fermentation, in accordance with previous investigations (Malbaša et al., 2009; Ilicic et al., 2013). Local kombucha was cultivated on black tea (1.5 g/L) with dissolved sucrose (70 g/L). The tea was cooled to room temperature, after which the inoculum from previous fermentation was added in concentration of 10 %, v/v. Incubation was performed at 25ºC for 7 days. The concentration of kombucha inoculum (8.5 % total solids) was completed in vacuum rotary evaporator at the temperature of 40 °C, up to 55.6 % total solids. Kombucha was used as inoculum in amounts of 15 mL/L and 30 mL/L for production of fermented milk beverages. Pasteurized cow’s milk from , a local dairy company AD Imlek (grad, država) was used for the production of kombucha fermented milk beverages. After homogenization and heat-treatment, milk was precooled and poured in sterilized 10 L stainless steel containers with lid and stirrer and then tempered at 43°C. The milk was inoculated with evaporated kombucha inoculum in concentration of: 15 mL/L and 30 mL/L. Second series of samples were manufactured from homogenized and heat-treated milk with addition of transglutaminase (TG). TG was added to milk tempered at 40 °C at a concentration of 0.02 % (w/w). After 2 hours, the enzyme TG was inactivated by heat treatment at 80 °C for 1 minute. After inactivation of TG, the milk was cooled at 43 °C and inoculated with evaporated kombucha inoculum in concentration of: 15 mL/L and 30 mL/L. In all cases, the changes of pH during the milk fermentation process were measured, and the fermentation was stopped when pH 4.5 was reached. The gels were then cooled down to 20±2°C, stirred for 1 minute and packed in adequate, smaller, containers (280 mL PP plastic cups with lids) and placed in storage at 5±1 °C until further analyses. The 300 mL glass jars with set kombucha fermented milk with added TG were directly transferred to the cold room at pH 4.5±0.1, until the rheological and textural testing can be carried out, on day 1 of storage. The four different kombucha fermented milk beverages without or with addition of TG are manufactured. The samples hereinafter referred to as K or KTG, where K refer to added level of evaporated kombucha inoculum in concentration of: 15 mL/L and 30 mL/L, and KTG refers to added the same previous concentration of evaporated kombucha inoculum and level of transglutaminase of fermented milk. The particle set and stirred samples were designated by capitals and corresponding concentrations of evaporated kombucha inoculum: fermented milk product manufactured with concentrated kombucha inoculum (15 mL/L) without TG addition (K15), fermented milk product manufactured with concentrated kombucha inoculum (30 mL/L) without TG addition (K30), fermented milk product manufactured with concentrated kombucha inoculum (15 mL/L) with TG addition (KTG15) and fermented milk product manufactured with concentrated kombucha inoculum (30mL/L) with TG addition (KTG30). The samples were prepared in duplicates, and the experiment was replicated twice.

Physico-chemical analyses

The following physicochemical properties were determined in all stirred samples (Carić et al., 2000): total solids (TS) by oven drying (Sutjeska, Serbia) (ISO 6731, IDF 21, 2010), total proteins (TP) by the Kjeldahl method using Kjeldahl’s distillation apparatus ( ISO 8968-1, IDF 20-1, 2016) and fat (F) by Gerber method using Gerber’s centrifuge (1200 g, Germany) (ISO 488:2008) while total carbohydrate (C) in fermented milk samples was produced by the fermented kombucha inoculum and with addition of transglutaminase which was calculated using C=TS-(F+TP+Ash). Based on the chemical composition, energy value (EV) of each beverage was calculated (EV=4.186x(9.3xF+4.4xP+4.1xC)). The pH measurements were obtained using a pH-meter (EcoScan pH 6 Eutech Instruments, Netherlands). The data were expressed as means and standard deviation using the software program; origin 8.3.1 and statistica. One way analyses of variance (ANOVA) and Tuckey’s studentized range (5 % significance) were carried out to test any significant differences between the results.

Rheological measurement

Rheological properties of samples were measured at 5°C using the HAAKE RheoStress 600HP (Karlsruhe, Germany) viscometer fitted with sensor PP60Ti (gap 1mm). The samples of set and stirred fermented milk products were taken with a spatula and placed a 2 mL sample on the rheometer plate and were allowed to achieve the temperature of 5 °C. The flow curves were obtained by implementing shear stress at shear rate which was increased from 0 to 200 s -1 in 180 s, held constant at 200 s -1 until total system destruction, and decreased from 200 to 0 s -1 in 180 s. Other rheological parameters considered were the area under the upward flow curve, the area difference under effects of upward and downward flow curves (ΔA or hysteresis loop area) (Hassan et al., 2003). The magnitude of gels thixotropic break down, that is coefficient of thixotropic break down (Kd). Kd is an index defined as the ratio of the hysteresis area to the area beneath the ascending shear curve (Dokić et al., 1999): Kd=Aup-Adown/Aup, where the areas under ascending (Aup) and descending flow curves (Adown).

Textural analyses

Textural properties (firmness, consistency, cohesiveness and index of viscosity) of the produced samples were analysed by Texture Analyser TA.HD.plus (Stable Micro System, Godalming, England) conducting a single compression test, and using a back extrusion cell (A/BE) disc (diameter 35 mm; distance 30 mm; speed 0.001 m/s) and an extension bar, a 5 kg load cell at 5 ºC. The extrusion disc was positioned centrally over the sample container. Using the options Return to Start, a trigger force of 10 g was applied. All measurements of set and stirred beverages were repeated three times.

Sensory evaluation

The sensory characteristics of set and stirred fermented milk beverages obtained by concentrated kombucha inoculum and with transglutaminase addition, comprising of appearance, colour, consistency, odour, taste, were evaluated by a panel of 10 assessors, 6 female and 4 male employees of the Faculty of Technology Novi Sad. The panellists were experts trained to evaluate the selected quality properties. The samples were poured into 100 mL plastic container, coded and stored at 4-6 °C, which is a temperature commonly used for sensory evaluation of kombucha fermented milk beverages with addition of TG. The panellists evaluated sensory characteristics using descriptive test and 5-point category scale were used. All the analyses conducted in this evaluation were repeated three times and performed after the production of set and stirred beverages (Radovanović, Popov-Raljić, 2001; Milanović et al., 2017).

Results and discussion

Chemical composition

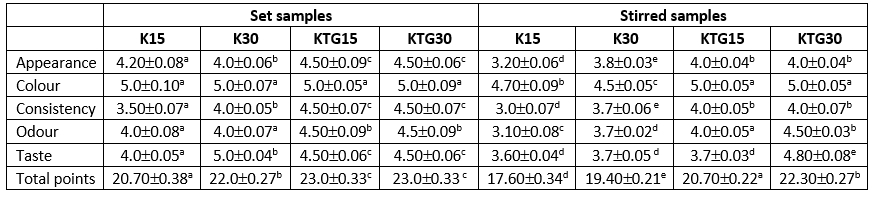

Chemical composition of concentrated kombucha inoculum, milk and kombucha fermented milk beverages with or without TG addition is presented in the Table 1. It is evident that inoculum concentration and addition of TG significantly impacted the chemical characteristics and energy value of kombucha fermented milk beverages. Chemical analyses demonstrated that kombucha fermented milk products without TG addition contained low level of total solids (11.34 g/100 g, sample K15 and 12.03 g/100 g, sample K30) compared to the total solids of samples produced with TG addition (11.49 4g/100 g, sample KTG15 and 12.27 g/100 g, sample KTG30). The protein content in the samples differed from 2.67 % (sample K15) to 2.93 % (sample KTG15), and was lower with respect to the milk. The calculated content of carbohydrate in fermented milk beverage obtained by 30 mL/L concentrate kombucha was higher than in sample produced by application 15 mL/L concentrate kombucha. The differences in gross chemical composition of kombucha fermented milk beverages affect energy value of products. Energy value of samples obtained by 15 mL/L concentrate kombucha inoculum is 193.37 kJ/100g and 14.5 % lower than the energy value of sample produced with 30 mL/L concentrate kombucha inoculum. Sample obtained by 30 mL/L concentrated inoculum had the highest energy value (226.35 kJ/100 g). Average energy values of kombucha fermented milk beverages were lower compared to data reported in the literature (Malbasa et al., 2009; Popovic et al., 2016). Milk – based beverages obtained by application of several different concentrates of kombucha starters have been investigated by Malbaša et al. (2009). The aforementioned authors found that the energy value of sample produced from milk of 2.2 % fat content with addition of 10 % and 15 % (v/v) concentrates of kombucha cultivated on black tea varied from 233 to 240 kJ/100 g. Popovic et al. (2016) investigated fermented milk products from milk with 0.9 and 2.2% fat obtained by 10 and 15 % (v/v) native kombucha inoculum. They found that energy value of kombucha fermented milk with 0.9% fat content was 199 kJ/100 g, and 15 % lower than energy value of sample produced from milk with 2.2 % fat content (235 kJ/100 g). In order to compare the differences between chemical compositions of such products, Tukey`s test was performed and the following results were obtained (Table 1).

Table 1. Chemical characteristics of concentrated kombucha inoculum, milk and set kombucha fermented milk products

Means in the same column with different small letter superscripts indicate significant difference at P < 0.05 among fermented milk products.

*Standard deviation not known; **Calculated value. ***Energy value (EV)

K15, Fermented milk product manufactured with concentrated kombucha inoculum (15 mL/L) without TG addition; K30, fermented milk product manufactured with concentrated kombucha inoculum (30mL/L) without TG addition; KTG15, Fermented milk product manufactured with concentrated kombucha inoculum (15 mL/L) with TG addition; KTG30, fermented milk product manufactured with concentrated kombucha inoculum (30mL/L) with TG addition (0.02%, w/w)

Textural characteristics

The texture of fermented milk product is important with regard to the quality of the products. The literature data indicate significant influence of milk composition, inoculum tea type and concentration and of transglutaminase addition on the textural characteristics of fermented milk products obtained by kombucha (Malbaša et al., 2015; Iličić et al., 2013; 2014).

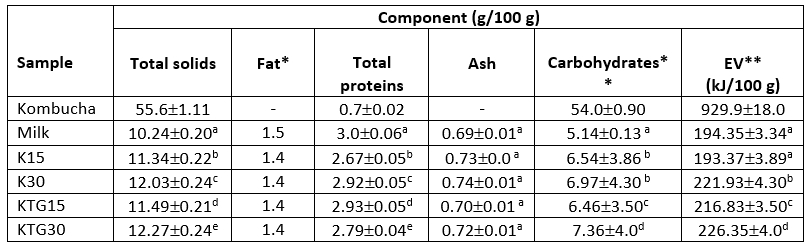

Textural characteristics of set and stirred fermented milk product obtained by concentrated kombucha inoculum with addition of TG are presented in Fig.1. The measured textural characteristics of the samples were firmness, consistency, cohesiveness and index of viscosity.

Figure 1. Influence of concentrated kombucha inoculum, with and without TG addition on textural characteristics of set and stirred fermented milk beverages (a) firmness (b) consistency (c) cohesiveness and (d) index of viscosity

The set sample with 15 mL/L concentrated inoculum with TG addition had the highest textural characteristics (firmness 149.23 g, consistency 3263.81 g, cohesiveness -104,89 g and index of viscosity -192,17 gs), while both of the samples without TG addition had the lowest textural characteristics. The obtained results can be explained in relation to the findings of Bonisch et al. (2007), who reported that about 80 % of TG induced cross-linking effect occurred above pH 5.7. Evidently, the samples with TG addition were exposed to the pH above this critical value for a longer period of time, which allowed prolonged cross linking of proteins during the fermentation. The topic of the effect of kombucha starter culture on the gelation process and textural properties during milk fermentation formed the subject of elaborate investigations by Vukic et al. (2014). At the end of the fermentation process at pH 4.6, yoghurt had the highest value of firmness (204.01 g) and consistency 5377.62 gs. According to this research, kombucha sample had higher value of firmness and consistency 28.44 g and 128.73 gs, respectively than the probiotic fermented milk. Iličić et al. (2013) found out that fermented milk produced from milk of 0.9 % fat content and manufactured by 10 % v/v kombucha inoculum had firmness of 27 g and consistency of 585 gs.

Also, it was found that inclusion of TG in milk increased the firmness and consistency in sample produced with probiotic starter and had firmer and stable structure than kombucha fermented milk products. The samples made by concentrated inoculum and with TG addition had much better textural characteristics compared to samples produced from milk with 0.9 % fat and with addition of 10 % v/v native kombucha inoculum by application of TG (Iličić et al., 2013), but rather poor compared to probiotic fermented milks.

In most studies, the textural properties of fermented milk products were significantly increased with the incorporation of TG compared to the control samples. The cross linking of milk proteins triggered by TG through formation of additional covalent ε-(γ-glutamyl) lysine) bonds, improves the yoghurt strength. The addition of a minimum TG level (0.01 %) in milk obtained by kombucha inoculum increased the hysteresis loop due to the increased crosslinking of the protein structure and that way resulted in satisfactory textural attributes (Iličić et al., 2014; Milanovic et al., 2009; Gharibzahedi et al., 2018). Set samples without TG addition had approximately three to four times higher firmness and consistency in comparison to the stirred samples. On the other hand, significant differences in firmness and consistency between set and stirred samples were noticed. Stirred samples had 6-7 times lower values of textural characteristics compared to set samples. Stirred samples produced with 15 or 30 mL/L concentrates kombucha inoculum and with TG addition had 21.16 % and 38.24 % higher firmness and consistency, respectively compared to samples without TG addition. Our results are in accordance with literature that investigated kombucha fermented milks produced from milk with different fat content and using different types of tea and concentrations of kombucha inoculum. Malbasa et al. (2015) investigated the textural characteristics of fermented milk products obtained by kombucha with various tea types and used with milk with of different fat content. Our results of the stirred kombucha fermented milk with added TG are in accordance with the samples produced from milk of 2.8% fat content. Textural characteristics of three different fermented dairy products (from milk of 2.8 % fat) obtained by conventional and non- conventional starter cultures were analysed by Vukic et al., (2018). Firmness and consistency of kombucha fermented milk samples were 14.28 g and 356.54 g, respectively, while cohesiveness and index of viscosity were -8,90 g and -3,27 gs, respectively. Stirred probiotic fermented dairy products made with of 0.1% fat and added TG had higher textural characteristics compared to the kombucha fermented milk products with TG addition (from milk with 1.5 % fat).

Sensory characteristics

Sensory evaluation of texture is often carried out as part of a full sensory profiling, which can also provide information on odour, flavor and texture of the products. For set type of fermented milk products, gel firmness and mouth thickness are the most important parameters. Ropiness as well as mouth thickness are important characteristics of stirred yoghurt.

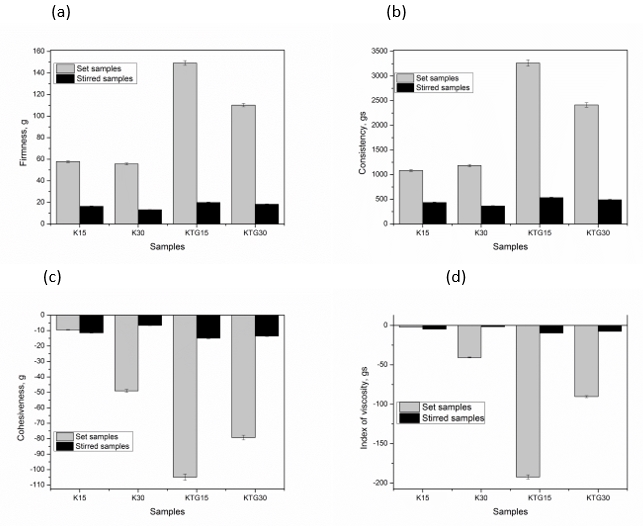

Table 2. Sensory profile of set and stirred kombucha fermented milk products with and without TG addition

Means in the same row with different small letter superscripts indicate significant difference at P < 0.05 among fermented milk products. K15, Fermented milk product manufactured with concentrated kombucha inoculum (15 mL/L) without TG addition; K30, fermented milk product manufactured with concentrated kombucha inoculum (30mL/L) without TG addition;KTG15, Fermented milk product manufactured with concentrated kombucha inoculum (15 mL/L) with TG addition; KTG30, fermented milk product manufactured with concentrated kombucha inoculum (30mL/L) with TG addition (0.02%, w/w)

Table 2 compares the results of selected sensory attributes: appearance, colour, consistency, odour and taste between set and stirred kombucha fermented milk gels with and without TG. A certain difference between sensory characteristics of kombucha fermented milk beverages might be expected. The addition of TG in milk significantly improved consistency of set and stirred products. These sensory characteristics are in accordance with textural parameters. Total sensory scores of samples were in the range from 17.84 (stirred sample K15) to max. 23.0 (set samples KTG15 and KTG30). The consistency of set samples with TG enzyme is homogenous and whereas samples produced without TG have grained consistency. So, the consistency and the taste score was greater in kombucha fermented product with TG than in samples without TG. It is evident that the set and stirred sample KTG3.0 had the best sensory characteristics. In conclusion, the test results can all be correlated with specific rheological characteristics.

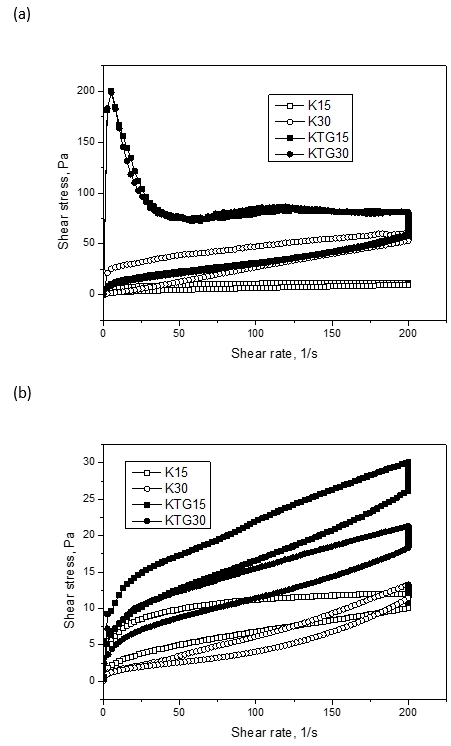

Rheological properties of kombucha fermented milk samples

Differences in chemical and textural characteristics between samples affected flow curves of set and stirred samples. Effects of transglutaminase (TG) addition on rheological properties of kombucha fermented milk samples are given in Fig. 2. All samples exhibited a thixotropic behaviour. It is evident that both of set samples containing TG showed higher shear stress at lower share rates compared to the samples without TG addition. The apparent viscosity, yield stress and values of hysteresis loop area are important rheological characteristics of kombucha fermented milk beverages. The apparent viscosity of set samples, varied from 8.37 Pas (sample K30) to 74 Pas (sample KTG30) after production. Yield stress of set samples were 98.43 Pa (sample K15), 21.58 Pa, (sample K30), 183 Pa (sample KTG15), 181 Pa (sample KTG 30). Set and stirred kombucha fermented milk products with and without TG had significantly higher values of the apparent viscosity, as well as the yield stress compared to three different fermented dairy products obtained by conventional (probiotic and yoghurt) and non-conventional ( kombucha) starter culture investigated in the research (Vukic et al., 2018).

Figure 2. Flow curves of fermented milk beverages manufactured with concentrated kombucha inoculum with and without TG crosslinking prior inoculation (a) set product (b) stirred products

The hysteresis loop area is the indicator of fermented milk structural breakdown and rebuilding during shearing (Paseephol et al., 2008). Fermented milk product with TG produced using 15mL/L concentrated kombucha inoculum showed the highest hysteresis loop area (11420 Pa/s), followed by fermented milk product with 30mL/L concentrated inoculum and TG addition (11300 Pa/s) and kombucha fermented milk samples without TG (4247 Pa/s, sample K15) and (3879 Pa/s, sample K30) (Fig. 2). Generally, fermented milk samples produced with concentrated kombucha inoculum showed significantly higher value of hysteresis loop area than samples with native kombucha inoculums (non-concentrated) (Iličić et al., 2013). The overall results of set samples without TG addition are significantly higher compared to three fermented dairy products obtained by conventional and non-conventional starter cultures which value varied from 4045 Pa/s (probiotic yoghurt) to 910 Pa/s (kombucha fermented dairy product) (Vukic et al., 2018). The gel stirring significantly affected rheology and flow behaviour of fermented dairy products. Hysteresis of loop area (HLA) of stirred samples is significantly lower compared to HLA of set products and value are 792. 4 Pa/s (sample K15), 749.8 Pa/s (sample K30), 1297 Pa/s (sample KTG 15), 986.6 Pa/s (sample KTG 30). The obtained HLA results of stirred kombucha fermented milk product with and without TG are higher compared to literature data (Vukić et al., 2018; Iličić et al., 2013).

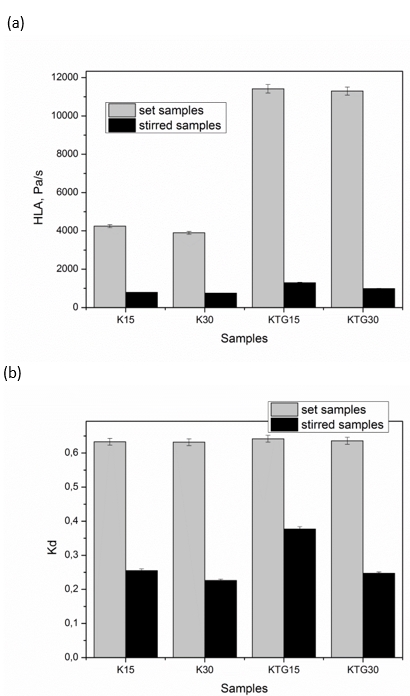

Figure 3. Comparing rheological properties of set and stirred fermented milk beverages manufactured with concentrated kombucha inoculum and TG addition: (a) hysteresis loop area and (b) coefficient index of kombucha fermented milk products

The differences in hysteresis loop magnitudes of gelsʹ thixotropic behaviour were calculated as coefficient of thixotropic breakdown (Kd) presented in Fig. 3. The thixotropic breakdown is the index of energy needed to destroy the structure of the system. The highest value of Kd was noticed with set samples KTG15 (0.642), while the sample KTG15 needed the highest energy to breakdown structure. On the other hand, coefficient of thixotropic breakdown of stirred samples varied from 0.226 to 0.377, which was significantly lower compared to set samples. The differences between our results and literature data (Vukic et al., 2018) could be explained by the influence of the different concentrations and types of kombucha inoculums used. Our kombucha inoculum was concentrated and added to milk at concentrations of 15mL/L and 30 mL/L, while in literature data (Vukic et al., 2018) kombucha inoculum was administered in native form at concentration of 10 %,v/v.

These results showed that significant decrease in apparent viscosity, yield stress and hysteresis loop area after the stirring for all samples is a result of gel destruction during the stirring. Stirred samples with TG had 90 % lower hysteresis loop area compared to set samples. HLA of stirred samples without TG was 60 % lower compared to set samples. The conclusions are in accordance with Mokoonlall et al. (2016) who presented the structural changes happening at the different post-processing levels of operations. The initial set fermented milk gel has a structure of 100%, while the structure of stirred samples varied from 20 % to 70 %. They also revealed that post processing unit operation like mechanical treatment significantly reduces viscosity of the stirred yoghurt final product.

Conclusions

The present study has investigated the impact of different kombucha inoculum concentrations and transglutaminase on chemical composition, sensory, textural and rheological properties of set and stirred fermented milk beverages. Our findings indicated that adding transglutaminase to milk before fermentation could significantly improve textural, rheological and sensory characteristics of the set and stirred kombucha fermented milk beverages compared to the gels from TG untreated milk. The addition of TG into stirred yoghurt contributed to an increase in fermented milk beverage network strength, viscosity, texture as well as sensory characteristics, but it was significantly lower compared to characteristics of set kombucha fermented milk beverage. Further research should be directed towards studying detailed characterisation and following rheological changing during storage of new developed fermented products obtained by concentrated kombucha inoculum with addition of transglutaminase.

Acknowledgements

Authors would like to thank the Ministry of Education, Science and Technological Development of the Republic of Serbia for the financial support for this article, Grant 451-03-9/2021-14/200134. Also, they are grateful to Ajinomoto Company for gratis samples of enzyme transglutaminase.

Poboljšanje teksture i reoloških svojstava čvrstih i tekućih kombucha fermentiranih mliječnih napitaka s dodatkom transglutaminaze

Sažetak

U radu je ispitana mogućnost proizvodnje fermentiranih mliječnih napitaka uz primjenu koncentriranog kombucha inokuluma i s dodatkom transglutaminaze (TG). Glavni ciljevi rada bili su ispitati utjecaj koncentriranog inokuluma kombuche i dodatka transglutaminaze na teksturalna, reološka i senzorska svojstva čvrstih i tekućih fermentiranih mliječnih napitaka. Rezultati pokazuju da dodatak transglutaminaze u mlijeko značajno utječe na teksturalna i reološka svojstva kombucha fermentiranih mliječnih napitaka. Čvrstoća i konzistencija kombucha fermentiranih mliječnih napitaka značajno je povećana primenom transglutaminaze u odnosu na kontrolni uzorak. Čvrsti uzorci s transglutaminazom imali su 90% veću površinu histerezisne petlje u usporedbi s tekućim uzorcima, dok je površina histerezisne petlje tekućih uzoraka bez transglutaminaze bila oko 60 % manja u usporedbi s čvrstim uzorcima kombucha fermentiranih mliječnih proizvoda. Enzimski tretman mlijeka s transglutaminazom poboljšao je teksturalna i reološka svojstva, i senzorske karakteristike čvrstih i tekućih fermentiranih mliječnih napitaka dobivenih primjenom koncentriranog kombucha inokuluma.

Ključne riječi: fermentirano mlijeko; kombucha inokulum; transglutaminaza; tekstura; reologija

References

https://doi.org/10.3168/jds.S0022-0302(03)73748-5

https://doi.10.1016/j.jfda.2018.02.002

http://doi.10.31015/jaefs.2020.3.3