Introduction

Throughout the process of cheese production, and after enzyme coagulation of casein, usually with chymosin, a pale-yellowish liquid "whey" is separated. Whey is the largest in volume byproduct obtained in the dairy industry containing proteins, fat, lactose, and minerals. About 47 % of the total whey quantity obtained from production of different cheese types worldwide was discharged into the sewage or soil (De Jesus et al., 2015). At the beginning of the 21 st century, the scientists’ focus was directed to valorization of the biological functionality of whey into value-added products. Primarily, whey was used for production of whey cheese. Research on whey reutilization is of particular interest in the production of functional beverages, organic acids, single cell proteins, organic fertilizers, biocatalysts, as well as bioplastics and energy/fuel products such as biofuel, biodiesel, bioethanol, biohydrogen, and microbial fuel cells. Whey valorization within final products has high impact in improving the wastewater quality and environmental protection (Tsermoula et al., 2021; Awasthi et al., 2022).

Whey proteins constitute around 20 % of milk protein content. The beneficial nutritional and health effects they possess provide for various application in food and pharmaceutical products. The most abundant whey proteins derived from cow milk are β-lactoglobulin (β-Lg), α-lactalbumin (α-La), bovin serum albumins (BSA), and immunoglobulin (Ig). Whey proteins are characterized with relatively high surface hydrophobicity which is the main parameter for protein structure alteration, and emulsifying and foaming capacities (Li et al., 2018). At pH values where proteins have a net zero charge (pI), attractive forces predominate and the protein molecules tend to associate resulting in their insolubility. The isoelectric point (рI) of the whey proteins is 5.2 (β-Lg), 4.7-5.1 (α-La), 4.7-4.9 (BSA), and 5.5-8.3 (Ig), Mehra et al., 2021. Whey proteins under influence of heat easily denatured and underwent structural conformational changes due to molecular unfolding. Protein conformation is most stable at a temperature of 25 °С, while the denaturation takes place at temperatures above 70 °С, but also, at lower temperature (-20 °С). The weak physical interactions stabilized the globular protein conformation. The unfolding of the peptide chain significantly increases its conformational entropy. This protein property was used to transform the whey into whey cheese. During milk pasteurization at temperature higher than 72 °С, whey proteins interact with the casein through disulfide (–S-S-) bonds. A typical example is β-Lg with κ-casein association when protein copolymer is formed. When cooling milk, most of these associations were irreversible which enables to obtain high cheese yield and whey with smaller quantity of β-Lg. Hydrophobic interactions lead to aggregation, coagulation and precipitation at the end. Whey protein aggregation through cross-linked disulfide bonds occurs at temperatures between 70 and 90 °С for about 10 minutes. Firstly, Ig-fraction denature, which is then followed by denaturation of BSA and β-Lg. α-La is the most stable fraction during heat denaturation (Liu et al., 2020; Markovska et al., 2021; Zhang et al., 2021).

"Urda" is cheese obtained by heat induced coagulation of whey proteins. Whey cheese production does not employ lactic acid bacteria, therefore, it does not require a ripening period, and can be sold only in few days after production. On the other hand, the shelf-life is notably shorter compared to other cheese types, because whey cheese is characterized by higher moisture content and water activity (Paskaš et al., 2019). Urda is one of the Macedonian dairy products with a long tradition usually obtained from whey which is a byproduct during production of semi-hard yellow cheese such as "kashkaval" or "beaten cheese" from sheep and cow milk (Pintado et al., 2001; Talevski, 2012).

This study aimed to investigate the impact of milk pasteurization temperature, type and pH value of whey, obtained from white brined cheese and Kashkaval production, on the yield and physicochemical, structural and sensory properties of the Urda.

Material and methods

Material

Whey was obtained as a by-product of the standardized industrial production process of white brined cheese (WBC) and Kashkaval (KAS) from cow’s milk at the Lactalis MK Dairy in Bitola, Republic of North Macedonia.

White brined cheese was produced from standardized milk (3.4 % proteins and 3.9 % fats). Milk pasteurization was performed for 5 minutes at temperature of 72 °С, 78 °С, 79 °С and 80 °С, respectively. After cooling to 39 °С, 40 % calcium chloride, thermophilic starter culture and enzyme (Alkaloid AD, Skopje, Republic of North Macedonia) were added into the pasteurized milk. Small cheese curds formed during coagulation process were poured into plastic molds, and the drained whey was collected in tanks. The production process of white brined cheese lasted for approximately 2.5 hours, starting from filling up the open vats to releasing the cheese curds.

In Kashkaval production, standardized milk (3.4 % proteins and 3.2 % fats) was pasteurized at temperature of 72 °С for 1 minute and cooled to 33 °С. 40 % of calcium chloride (Alkaloid AD, Skopje, Republic of North Macedonia), thermophilic culture and enzyme were then added into the tank with pasteurized milk and the temperature was raised to 40 °С for 10 minutes. After coagulation, whey was separated into tank, while cheese curds were poured on self-pressing presses (20 minutes), followed by stretching at temperature of 72 °С with 6 % sodium chloride solution (Izvor, Vadin DOOEL, Skopje, Republic of North Macedonia). The total Kashkaval production lasted for approximately 3 hours.

Manufacture of Urda

Urda was produced at the Lactalis MK Dairy according to the industrial production technology in four batches (n = 4). Whey had to be processed within 2 hours after draining in order to prevent quality losses, and to obtain higher Urda yield. In a stainless steel tank with direct saturated steam, whey was gradually heated, along with continuous stirring from 30 to 75 °C, and then the whey pH is adjusted in the range between 4.5 to 6.0 with 20 % citric acid (Alkaloid AD, Skopje, Republic of North Macedonia) to evaluate the influence of pH value on Urda yield. The heat treatment continued up to the temperature of 90 °C, which was reached in about 1.5 hours. After holding for 20 min at 90 °C temperature, the whey, with coagulated and floated proteins on the surface, was transferred onto the stainless steel mesh (thickness 0.25 mm, square holes 0.75 x 0.75 mm) and left to drain for 8 hrs at room temperature (20±1 °C). Urda was then stored at 4 °C for further analysis.

Physicochemical analyses and sensorial evaluation

Whey samples. Content of dry matter, fat and protein were determined by Milkoscan FOSS F1 (Hillerǿd, Denmark). The pH values were measured using a digital pH meter Mettler Toledo SevenEasy TM S20 (Greifensee, Switzerland). The influence of milk pasteurization temperature for WBC production was evaluated by calculating the differences (DIF) in the dry matter, fat and protein in the whey, and comparing the values obtained at lower temperature (72 °C) to higher temperature (78 °C, 79 °C, and 80 °C) by using Eq. [1]. The difference of whey obtained at same temperature of milk pasteurization (72 °C) for KAS and WBC production, was evaluated by using Eq. [2].

DIF (%) = [(WBC 72 – WBC 78, 79, 80)/ WBC 72] · 100 Eq. [1]

DIF (%) = [(KAS 72 – WBC 72)/ KAS 72] · 100 Eq. [2]

Urda samples. The total dry matter (DM) was determined by using Mettler Toledo Moisture Analyzer HB43 (Greifensee, Switzerland) and water activity (aw) with aw - meter type Testo 650 (Cole-Parmer, Vernon Hills, IL, USA). The yield was calculated as Urda quantity obtained from 1L whey by using Eq. [3]. The total protein based on the nitrogen content (N × 6.38, Kjeldahl method, no. 991.20) and fat content (butyrometric Gerber method, no. 200.18) was determined according to the AOAC (2006). The content of fat (FDM) and protein (PDM) expressed on a dry matter basis were calculated by using Eq. [4], and Eq. [5], while the moisture content on a fat-free basis (MFFB) by using Eq. [6].

Yield (g/L) = Urda/Whey [3]

FDM (%) = (Fat/DM) · 100 [4]

PDM (%) = (Protein/DM) · 100 [5]

MFFB (%) = (Water/100 – Fat) · 100 [6]

Textural properties. TA-XTplus Stable Micro System (Godalming, UK) was used with the penetration test. Urda sample was formed in a round plastic mold (100 mm diameter and 47 mm height) to 40 mm in height. The probe that was used to test the sample was 20 mm in diameter and 10 mm height. Data on hardness, cohesiveness, elasticity index, and secondary of gumminess and chewiness were obtained via the TPA test.

Colour parameters. L* lightness (100 white/0 black), a* (+red/-green) and b* (+yellow/-blue) were measured using a Dr. Lange spectra colorimeter (Chelmsford, UK). The samples were placed in a 1 cm cell. L*, a*, and b* values were determined at D65 light source and 10° observer angle. The standardized values for a white plate were L* = 95.93, a* = −0.19, and b* = 3.12. Whitening index (WI) and yellowish index (YI) were calculated by using Eq. [7] and Eq. [8].

WI = 100 – [(100 - L*) 2 + (a*) 2 + (b*) 2] 1/2 [7]

YI = 142.86 · b*/L* [8]

Sensory evaluation. Appearance (exterior, interior), texture (body) and flavour (odour and taste) were evaluated by team of trained panellists (n=10), according to ISO 22935 standard method (ISO, 2009). All these attributes were scored on a scale from 0 to 10 ("0" lowest/"10" highest). According to the importance given to each attribute, the scores for appearance were multiplied by a factor 1 (10 maximum scores), body texture by 4 (40 maximum scores), and flavor by 5 (50 maximum scores). Total scores were calculated as a sum of values of appearance, body texture and flavour. Maximum score of total sensory attributes was 100.

Statistical analysis. Statistical analysis of the results was run with the software SPSS Statistics version 23, (IBM, New York, NY, USA) using the Wilcoxon signed rank test for dependent samples. The data were analyzed with one-way ANOVA, followed by multiple comparisons with Tukey's honest significant difference (HSD) test at 5 % significance level ( p < 0.05).

Results and discussion

Physicochemical composition of whey

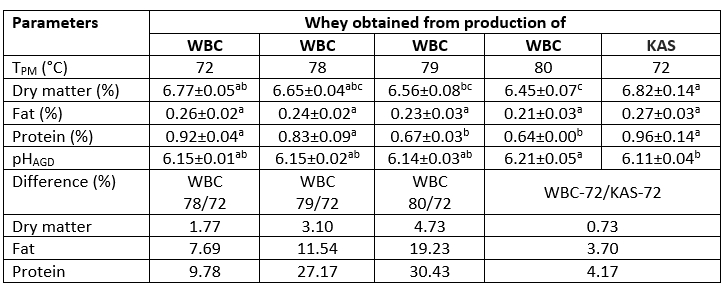

The average values of the physicochemical parameters of the whey obtained as a by-product of Kashkaval (KAS) and white brined cheese (WBC) produced from cow’s milk are presented in Table 1. Whey obtained during production of WBC at different milk pasteurization temperature showed significant differences (p<0.05) in chemical composition. A lower content of dry matter (DM), protein and fat was determined in WBC whey obtained at higher pasteurization temperatures. WBC whey with the highest content of DM (6.77 %), fat (0.26 %) and protein (0.92 %) was obtained at 72 °C. By increasing the pasteurization temperature from 72 °C to 80 °C, the whey protein content decreased from 0.92 % to 0.64 %. The protein content in WBC whey obtained at 78 °C, 79 °C and 80 °C is decreased for 9.78 %, 27.17 % and 30.34 %, respectively, compared to the protein content in WBC-72 whey. The dry matter and fat content in WBC-80 whey was lower for 4.73 % and 19.23 % comparing to the WBC-72 whey. Cheese production processes, that is, KAS-72 compared to WBC-72, insignificantly influence the whey physicochemical characteristics. KAS-72 whey was characterized with slightly higher content of dry matter (6.82 %), fat (0.27 %) and protein (0.96 %) than WBC-72 whey.

Table 1. Physicochemical characteristics of whey 1

1Mean value (n = 4) ± standard deviation (SD). Different letters in the same row are statistically significant (Tukey test, p<0.05). WBC - White brined cheese. KAS - Kashkaval. T PM - pasteurization temperature. pH AGD - pH value after curd drainage.

Whey composition is affected by several factors, including the type of milk and processed cheese, temperature and time of milk heat treatment, methods of casein precipitation, concentration of calcium added, and time after whey drainage. Heat treatment causes changes in the configuration, structural and functional properties of milk proteins, mainly, denaturation of the whey proteins, their interaction and complex formation with k-casein at the surface of casein micelles, that results in additional retention of whey proteins in cheese, and increase of the casein micelles size. The most widely used commercial method for milk heat treatment is pasteurization at temperature of 72 °C for 15 seconds. At longer heat treatments or by increasing the temperature to over 80 °C, the denaturation of whey proteins rapidly increases, while the size of casein micelles increases at slower rate (Lepesioti et al., 2021; Syed et al., 2021). Decrease in the protein content in WBC whey by increasing pasteurization temperature (Table 1) corresponds to the results reported in the literature. In cow’s milk which was pasteurized for 26 seconds, the decrease in whey protein content increased from 2.8 % at 72 °C to 34 % at 87 °C compared to the total whey protein in raw milk (Rynne et al., 2004). Degradation level of whey protein depends on the milk type. In goat milk which is pasteurized at high temperature (72 °C, 75 °C, and 81 °C) and for short time (15 sec. and 25 sec.), whey protein denaturation is lower than in cow milk (Prasantha and Wimalasiri, 2019). In whey protein isolate solutions, whey protein denaturation increased by increasing the temperature from 72 °C to 85 °C, while the increased Ca concentration (1 to 5 mM CaCl 2) positively affects the whey protein aggregation (Joyce et al., 2018).

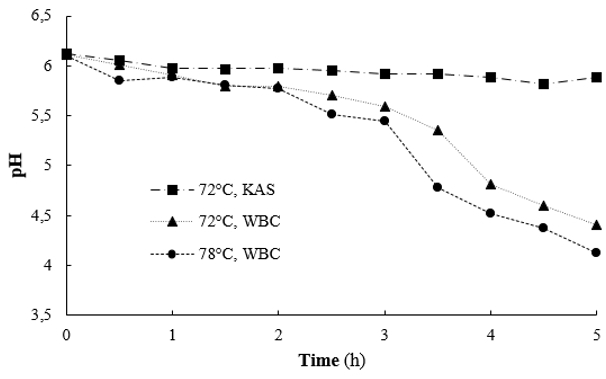

According to the determined pH values, whey obtained during production of WBC and KAS could be classified as sweet. The influence of milk pasteurization temperature was insignificant on the pH values of the WBC whey. pH values of WBC whey varied from 6.14 to 6.21. KAS whey was characterized by pH 6.11 (Table 1). Sweet whey with pH values ranging from 5.8 to 6.6 is drained as by-product during production of ripened hard or semi hard cheese (Kumar et at al., 2016). After curd draining, pH values of the whey from WBC production decreased rapidly over time (up to 5 hours), while in this period, significant decrease in the pH values in KAS whey was not determined (Figure 1). In the liquid whey that was not pasteurized or cooled to low temperatures, the active culture continued to grow and to produce lactic acid mainly that initiated increase of the acidity during storage (Muhammad et al., 2018; Hanková and Čížková, 2020). When WBC production is performed in open vats where manual operations are involved, the possibility of microbial contamination and pH decrease is higher in comparison to KAS production in tanks.

Figure 1. Whey pH values after draining

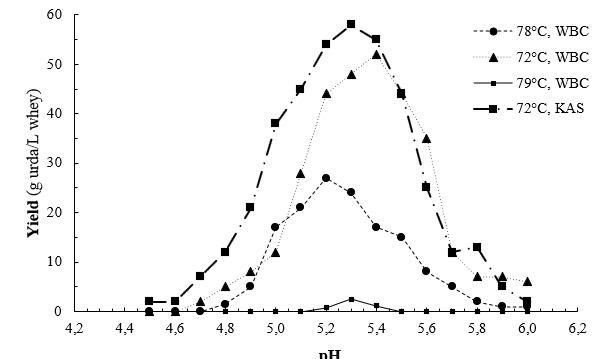

Yield of Urda

The influence of whey pH values on Urda yield was studied in the WBC and KAS whey, varying the pH between 4.5 and 6.0 (Figure 2). The yield of Urda corresponded to the whey protein content (Table 1). The highest Urda yield was obtained from KAS whey at pH 5.3 (58 g/L). By increasing the milk pasteurization temperature, Urda yield from WBC whey decreased. The highest temperature of milk pasteurization to valorise whey into Urda was 78 °С. Maximum values of Urda yield from whey WBC-72 (52 g/L) and WBC-78 (27 g/L) were obtained at pH 5.4 and 5.2, respectively. Urda quantity (2.5 g/L) obtained from the WBC-79 whey is insignificant, which on the one hand is economically unprofitable, and the structure was spreadable without visible cheese curds (Figure 3), which is also not typical for this type of products. Given the low protein content in the whey drained from white brined cheese produced from pasteurized milk at 80 °С (WBC-80), obtaining of Urda was impossible. Quantity of WBC-72 Urda was 89.66 % from the total quantity of Urda KAS. Urda yield obtained from whey WBC-78 and WBC-79 was 48.08 % and 95.19 % lower compared to the quantity of Urda WBC-72.

Figure 2. Influence of whey pH value on the Urda yield

Figure 3. Visual appearance of Urda obtained from whey WBC-79

Temperature, salt type and concentration, and pH of the protein solution affect the whey protein thermal aggregation. Depending on these conditions, different protein aggregate types are formed. Protein aggregation rate increases with the presence of salt through a decrease in inter-protein charge repulsion or by forming salt bridges between proteins. In both mechanisms, electrostatic charge on protein molecules is important, which modifies at different pH values. Divalent salts, that is, mainly calcium chloride, cause increased protein aggregation compared to sodium chloride as representative of monovalent salts (Guinne, 2021). Generally, pH of the solution affects the nature and distribution of total charge of proteins. Whey proteins are soluble at low and high pH values (4.28 > pH < 7) due to excess of net charge causing a repulsion between molecules, and respectively, contribute to increasing the protein solubility. Whey protein aggregation and precipitation is easily performed at pH values of 4.8 to 5.3, which is a range of β-Lg and α-La isoelectric points, where net charge is 0 and the potential for protein-protein interaction is at its highest point. The milk pasteurization temperature has a high impact on the yield of Urda. At higher milk pasteurization temperatures, whey proteins are incorporated into the structure of the k-casein micelles by creating co-aggregates that reduce the whey protein content. After thermal treatment of whey with lower protein percentage, cheese grains of smaller size were produced and passed through the draining stainless steel net. Also, given that Urda is a by-product of cheese production, to obtain higher yield of white brined cheese, it is more convenient to adapt the pasteurization temperatures up to 78 °С. At 72 °С milk pasteurization temperature, the yield of white brined cheese decreases, and the price increases related to the higher quantity of raw materials used (Dissanayake et al., 2013; Krishna et al., 2021).

Physicochemical composition of Urda

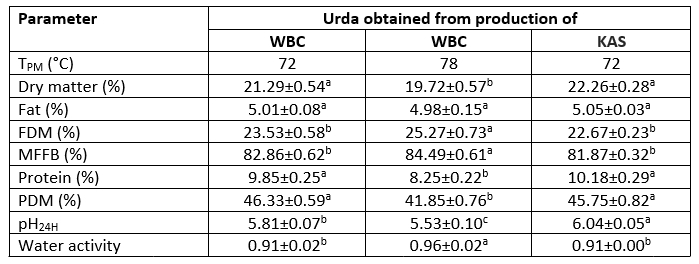

Table 2 presents the summary of physicochemical characteristics of Urda obtained from WBC-72, WBC-78, and KAS whey.

Urda WBC-78, compared to Urda WBC-72 and KAS is characterised by the lowest values of the dry matter (19.72 %), fat (4.98 %), protein (8.25 %), pH (5.53) and the highest value of water activity (0.96 %) that decreases quality and shelf life. The differences between the average values of the physicochemical composition of Urda WBC *-72 and Urda KAS ** were insignificant (p>0.05). According to the criteria in the Regulation (Official Gazette of the RM No. 96/2011), based on the content of DM (min 20 %), FDM (min 25 %), and MFBB (higher than 67 %), the obtained Urda of whey from WBC and KAS was classified as low-fat soft albumin cheese. The data of physicochemical Urda characteristics presented in Table 2, are in correlation with data previously reported by Paskaš et al. (2019). In Urda obtained after production of Montenegrin semi-hard cheese, higher content of DM (42.85 %), fat (21.74 %), protein (13.66 %), FDM (50.77 %) and MFBB (49.67 %) was determined (Bojanic Rasovic et al., 2017).

Table 2. Physicochemical characteristics of Urda 1

1Mean value (n = 4) ± standard deviation (SD). Different letters in the same row are statistically significant (Tukey test, p<0.05). WBC - White brined cheese. KAS - Kashkaval. T PM - pasteurization temperature. FDM - Fat on a dry matter basis. MFFB - moisture on a fat-free basis. PDM - Protein on a dry matter basis. pH 24H - pH value measured 24 h after production

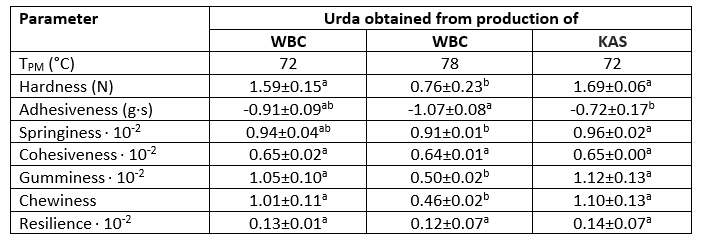

Textural characteristics of Urda

Hardness of Urda WBC-72 and KAS was significantly higher (p<0.05) than that of Urda WBC-78. The significantly lower content of DM and protein for WBC-78 (Table 2) resulted in two fold softer curd with more spread-like characteristics (Figure 3). The obtained differences in the values for adhesiveness, springiness, gumminess, and chewiness (Table 3) were insignificant (p>0.05). Urda WBC-72 and KAS were characterized by a more stable texture related to the higher protein content. The textural properties of Urda WBC-72 and KAS corresponded well to previously published data (Souza et al., 2016; Wu et al., 2020). Kaminarides et al. (2020) reported a higher value for hardness (7.40 N) in whey cheese with 3.94 % fat content.

Table 3. Textural characteristics of Urda 1

1Mean value (n = 4) ± standard deviation (SD). Different letters in the same row are statistically significant (Tukey test, p<0.05). WBC - White brined cheese. KAS - Kashkaval. T PM - pasteurization temperature

Colour characteristics of Urda

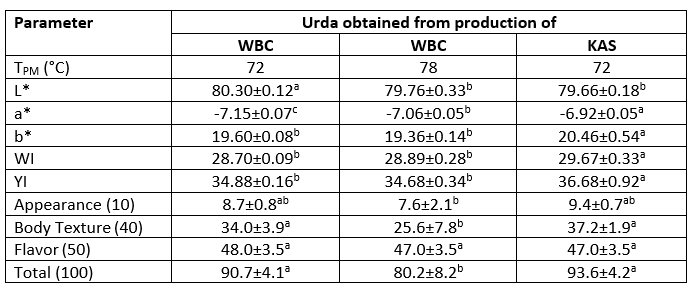

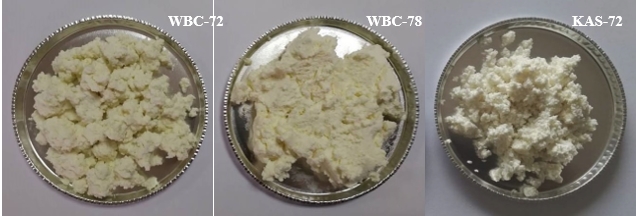

Table 4 shows the results for colorimetric parameters and sensory evaluation of Urda from WBC and KAS. Visual appearance of Urda is shown in Figure 4. Influence of the milk pasteurization temperature in the production of white brined cheese was not significant for the colorimetric characteristics of Urda WBC-72 and WBC-80. KAS Urda is characterized by a higher value for b * (20.46) and YI (36.68). Heat treatment of milk at 80 °C significantly reduced L*, a*, and b* values of whey beverages as was determined by Kelleher et al. (2018), which also impacts the consumer perception.

Table 4. Colorimetric parameters 1 and sensory evaluation 2 of Urda

1Mean value (n = 15) ± standard deviation (SD). 2Mean value (n = 10) ± standard deviation (SD). Different letters in the same row are statistically significant (Tukey test, p<0.05). WBC - White brined cheese. KAS - Kashkaval. T PM - pasteurization temperature. L* lightness (100 white/0 black), a* (+red/-green), b* (+yellow/-blue). WI - Whitening index. YI - Yellowish index. Total (100) - sum of values of appearance (10), body texture (40) and flavor (50).

Figure 4. Visual appearance of Urda

Sensory characteristics of Urda

The highest scores were received for Urda KAS (93.6) and WBC-72 (90.7). Urda WSC-78 was different by appearance and texture, which was confirmed at sensory evaluation receiving at least two scores less. Urda obtained from whey KAS and WBC-72 had noticeable grainy and sandy structure, while Urda WBC-78 was characterised by a more creamy and spreadable structure due to highest content of water and content of fat on a dry matter basis. Regarding the taste, no significant differences have been noticed. All three Urda types, WBC-72, WBC-78 and KAS, show specific fresh and milky taste, typical for this product (Pappa et al., 2020).

Conclusion

Industrial trials with whey obtained from white brined cheese and Kashkaval were successful in the context of Urda valorisation. The highest Urda yields from white brined cheese and Kashkaval whey were obtained in the pH range between 5.2 and 5.4, that is pI value of dominant whey proteins, β-Lg and α-La. Urda WBC-78 was characterized with smoother and creamy structure. Urda WBC-72 and KAS had more typical structure and texture for that kind of product. Sensory characteristics of Urda WBC-72 and KAS were similar and with the highest total sensory scores. The water activity of Urda WBC-78 was the highest and it is expected to have the shortest shelf-life and highest microbiological instability. Further research on these products will be aimed to determine their shelf-life and microbiological stability.

Utjecaj vrste sirutke na prinos i kvalitetu urda sira

Sažetak

U ovom je istraživanju u industrijskim uvjetima proizveden sir urda primjenom toplinske denaturacije koja je rezultirala koagulacijom i izdvajanjem proteina iz sirutke dobivene u procesu proizvodnje sira u salamuri te kačkavalja. Pritom je ispitivan utjecaj temperature pri kojoj je provedena pasterizacija, pH vrijednosti, sadržaja proteina i vrste sirutke na prinos i kvalitetu urde. pH sirutke kretao se između 4,5 i 6,0, a najveći prinos urde postignut je pri pH vrijednostima između 5,2 i 5,4. Pri korištenju sirutke dobivene proizvodnjom sira u salamuri kao ishodišne sirovine, najviši prinos urde postignut je pri temperaturi pasterizacije od 72 °C. Daljnjim povećanjem temperature do 80 °C padali su prinos urde kao i udio proteina sirutke. Vrsta korištene sirutke nije značajno utjecala na senzorska svojstva i parametre teksture urde, koja je svrstana u kategoriju niskomasnih mekih albuminskih sireva. Iskorištavanje sirutke koja zaostaje u proizvodnji sireva u salamuri te proizvodnja urde optimalnih funkcionalnih svojstava uz maksimalan prinos nije važno samo s ekonomskog stajališta, već može značajno utjecati i na poboljšanje kvalitete otpadnih voda.

Ključne riječi: sirutka; proteini; pH vrijednost; temperature pasterizacije, prinos urde

References

Liu, W., Chen, D.X., Jeantet, R., André, C., Bellayer, S., Delaplace, G. (2020): Effect of casein/whey ratio on the thermal denaturation of whey proteins and subsequent fouling in a plate heat exchanger. Journal of Food Engineering 289, 110175, 1-13. https://doi.org/10.1016/j.jfoodeng.2020.110175

Pappa, E., Kondyli, E., Bosnea, L., Mataragas, M., Giannouli, A., Tsiraki, M. (2020): Semi-industrial production of kashkaval of pindos cheese using sheep or a mixture of sheep-goat milk and the utilization of the whey for manufacturing urda cheese. Foods 9 (6), 736, 1-20.https://doi.org/10.3390/foods9060736