Introduction

The world’s production of goat cheese has increased by nearly 50 % since the 1990s and, in 2020, 510 819,48 t were produced (FAOSTAT, 2023). This indicates that the dairy industry, and the production of cheese, have recently undergone intensive development and attracted increased attention. Although milk production is more widespread in Asia and in Middle Eastern countries, according to Tilocca et al. (2022), goat cheese is a significant part of the Mediterranean diet and is among the most frequently consumed dairy products in the world, due to its nutritional and health benefits. Goat cheeses are generally produced by small-scale farmers who play an important role in global economic sustainability (Bodnár et al., 2021). Local production and specific resources contribute to the increased quality of life of both producers and consumers (Bramely, 2011). Additionally, dairy products made from goat milk can be classified as health-promoting dairy products (Paskaš et al., 2020). Goat milk is well known to be hypoallergenic and easily digestible, and is thus considered a nutraceutical (Clark and García, 2017) and an alternative to cow milk (Watkins et al., 2021). Therefore, dairy products from goat milk are highly demanded by the consumers (Han et al., 2021). The functional properties of goat cheese related to fatty acids (FAs) can be improved by specific animal-feeding regimens and by introducing feedstuffs that affects milk FAs into the dairy goats diets. As noted by Zanwar et al. (2016), nowadays, foods, especially dairy products, have become deficient in n-3 fatty acids, due to changes in the nutrition of dairy animals which is made visible in the transition from green pasture to concentrated feed intended to increase milk production. Therefore, many feedstuffs have been introduced to animal diets in order to increase n-3 FAs in dairy products, the most well-known of which is the extruded linseed. Recently, a new source of oilseeds has been tested in order to improve FAs in dairy products. One such potent feedstuff that could be used in ruminants´ feeding is the hempseed cake (Cannabis sativa L.) (Mierliță, 2018; Klir et al., 2019).

The global production of hemp seeds in 2021 was 5 566 t, with 68.9 % coming from Europe (FAOSTAT, 2023). Hemp seed oil content ranged from 25 to 35 % in a study conducted by Leizer et al. (2000). Hempseed cake (HSC) is a by-product produced after the cold-pressing of hemp seeds and is one of the most valuable sources of proteins which, according to House et al. (2010), may comprise up to 50 %. The European Commission (2022) set maximum total levels of delta-9-tetrahydrocannabinol (Δ9-THC) and delta-9-tetrahydrocannabinolic acid (Δ9-THCA) in its Commission Regulation regarding the content of hemp seeds, ground hemp seeds, and other processed hempseed products, which must not exceed the maximum value of 3.0 mg/kg.

As reported by Arango et al. (2022), HSC contains 28.2 % crude protein and 8.7 % crude lipids, in which the predominant FA was linoleic acid (C18:2 c9, c12 n-6, LA; 56.2 %), followed by oleic acid (C18:1 c9 n-9, OA; 15.8 %) and α-linolenic acid (C18:3 c9,c12,c15 n-3, ALA; 12.8 %); with its beneficial n-6/n-3 FAs ratio (4.4), it has the potential to ensure that dairy products contain beneficial FAs. Some studies show increased ALA and LA in sheep milk when feeding animals with 480 g/day of HSC (Mierliță, 2018) and with 175 g/d of hemp seeds (Mierliță, 2016). However, Ncogo Nchama et al. (2022) did not determine any significant effect of including 5 % HSC in dairy cow diets on the FAs content of their meat.

Since HSC have beneficial nutritional and health properties, and the potential to improve the FA profiles of animal products when introduced into their diets, this study aimed to research the effect of feeding dairy goats with diets enriched with HSC on the chemical composition and fatty acid proportions of semi-hard goat cheese produced on a family farm in a traditional way.

Materials and methods

This trial was carried out within the regulations of the Animal Protection Act of Croatia (NN 133/06, NN 37/13 and NN 125/13), the legal act on the protection of animals used for scientific purposes (NN 55/13), and other relevant acts determining the welfare of farm animals as approved by the Bioethics Committee for Research on Animals of the Faculty of Agrobiotechnical Sciences, Osijek (2158-94-02-19-06, 18th March 2019).

Experimental design

The trial was carried out at the family farm in the Osijek-Baranya County (the Republic of Croatia). After an adaptation period of 1 week for the new feeding strategy for goats, milk for traditional cheese making was collected at 45th, 60th, and 75th day in milk (DIM). This new feeding strategy implies hempseed cake inclusion in the diet for dairy goats. The milk was used to produce semi-hard cheese in a small-scale cheese making plant. The experiment lasted for 45 days (from 31st to 75th day of lactation), including 3 treatments within 3 processing periods (days of sampling).

Animals and feeding regime

The study was carried out with 28 French Alpine dairy goats at a family farm (Osijek, Osijek-Baranya County, Croatia). The kidding of goats occurred within a period of one week. Goats were subjected to the experiment at 31.0±2.7 DIM, after an adaptation period (7 days), which was necessary to adapt the rumen to a new experimental diet. All goats were kept together in the stable. Just before milking, forestripping was undertaken, and none of the goats presented mastitis. Goats were milked twice a day, in the morning and evening, using a milking machine. The goats were in good health status with body conditions normally found in lactating dairy goats (2.5 points), and were aged 2.8 years at the beginning of the experiment.

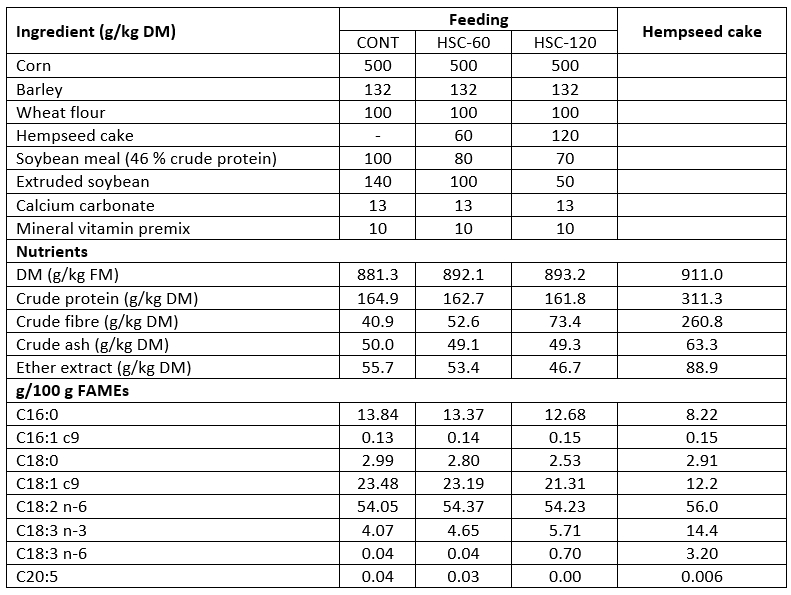

The feeding of goats was based on meadow hay ad libitum (~1600 kg/day/head), and on individual feeding with 600 g of concentrate mixture during the morning milking and 600g during the evening milking (1200 g/day/head), with an approximate ratio of hay and concentrate mixture of 60 %: 40 %. Concentrate mixtures were balanced according to the goats´ requirements as described by the National Research Council (2007), and were offered individually in separate feeding troughs within the milking parlour during morning and evening milking; no refusals of concentrate mixtures were observed during the experiment. Access to fresh drinking water was provided at all times. Dietary treatments had different content of HSC (0, 60, and 120 g/kg DM), which means that they differed in terms of the main sources of proteins and lipids. The HSC was a by-product produced from the cold pressing of hemp seeds of the Finola variety. First, the seeds were rinsed, dried, and dehulled, and then mechanically pressed to release oil, with temperatures not exceeding 50 °C. The main sources of protein in the control diet (CONT, 9 goats) were soybean meal and extruded soybeans. Soybean content was partially replaced in the concentrate mixture with 60 g/kg DM of HSC in the first experimental group (HSC-60, 10 goats), and with 120 g/kg DM of HSC in the second experimental group (HSC-120, 9 goats). The raw materials and nutrient composition of the concentrate mixtures and HSC are presented in Table 1.

This study was a part of a wider research project, whereby a part of the data related to milk performance was already published by Klir Šalavardić et al. (2021). Accordingly, morning milk yield was 1.41, 1.52 and 1.76 kg, milk fat content was 3.45, 3.19 and 3.18 g/100 g, milk protein content was 3.03, 2.93 and 2.86 g/100 g, and lactose content was 4.55, 4.41 and 4.50 g/100 g in CONT, HSC-60 and HSC-120, respectively. Klir Šalavardić et al. (2021) also reported a significant decrease in C18:0 and LA/ALA was detected in milk from goats fed with 120 g/kg HSC (DM basis).

Table 1. Raw material and nutrients of the concentrate mixtures used in the diets of lactating dairy goats

CON, control group without hempseed cake; HSC-60, concentrate mixture with 60 g/kg of hempseed cake; HSC-120, concentrate mixture with 120 g/kg of hempseed cake; FAMEs, fatty acid methyl esters.

Feed analysis

The feed was analysed using standard procedures and methods (AOAC, 2006). The Kjeldahl method was used to determine crude protein, while ether extract was determined using the universal extraction system (Buchi, Flawil, Switzerland). Additionally, concentrate mixtures and HSC were analyzed for their FA profiles. The fatty acid methyl esters (FAMEs) from the feed were prepared according to HRN EN ISO 12966-2:2017, and analyzed using an Agilent 7890B (Agilent, Santa Clara, USA) gas chromatograph with a flame ionization detector. This procedure was explained by Antunović et al. (2021). The FAMEs from the concentrate mixture and HSC were prepared according to HRN EN ISO 12966-2:2017. Then, 100-200 mg of the feed sample was prepared with 4 mL of methanolic sodium hydroxide (0.5M) in a 50 mL flask with 2–3 boiling chips. The flask was boiled under reflux for 20 min and 5 mL of methanolic boron trifluoride solution was added and boiled for 4 min. The FA extraction was carried out with n-heptane (5 ml) and boiled for 2 min. After cooling down the flask, a saturated aqueous sodium chloride solution was added. An upper n-heptane layer was transferred to a test tube that contained anhydrous sodium sulphate. Then, a 1 mL aliquot was taken for chromatographic analysis using an Agilent 7890B (Agilent, Santa Clara, USA) gas chromatograph with a flame ionization detector.

Cheese making

In total thirty-six cheeses were produced using traditional method in a small-scale cheese making plant on a family farm. The cheese was produced from three bulk tanks of milk corresponding to each dietary treatment (CONT, HSC-60 and HSC-120). Four cheeses were manufactured from each milk tank (morning milking). Cheese manufacturing was repeated three times during the experiment (at 45th, 60th, and 75th DIM), to obtain twelve cheeses per group, resulting in thirty-six cheeses made of nine bulk milk tanks in total. Milk from each group was collected in one bulk tank and processed within 24 hours of milking. The production of cheese included heating of milk to the temperature of 90 °C. After reaching this temperature milk was removed from heat and 100 mL of vinegar (9 % acetic acid) was added per 10 L of milk, and allowed to rest for ~10 min to coagulate. When it had reached the desired moisture and consistency, the curd was drained with whey removal and salted. The curd was placed into 350 g perforated plastic mold shapers and then rested at room temperature for 24 h. Then, the cheeses were vacuumed and stored in a freezer (-20 °C) until the analyses. The cheese was classified as semi-hard based on moisture content on a fat-free basis (International Food Standards, 1973).

Physicochemical analysis

The chemical composition of the cheese was obtained using standard procedures (AOAC, 2006) in duplicate values. The dry matter of cheese was determined as follows: 5 g samples of cheese were set in dried and cooled containers (30 min., 105 °C, 1 h of cooling) containing a fine laboratory sand for 1.5 h at 105 °C. After drying, samples were cooled for 1h in a desiccator and weighed; the % of moisture was calculated as the ratio between the container weight with the weight of the dried sample subtracted from the weight of the container containing the fresh sample, and the weight of the sample. The pH value was determined using a contact pH meter (Mettler Toledo, Greifensee, Switzerland), while cheese proteins were determined using Kjeldahl steam distillation (Behr, Germany). First, a cheese sample (0.5 g) was digested during boiling with sulfuric acid (8 mL) and ½ tablet of Kjeldahl in a digestion block at 400-450 °C for 1 hour. Then, 30 mL of NaOH (40 %) and 40 mL of H2O were added to the digested solution, liberating ammonia which was quantitatively steam distilled and determined by titration (NaOH 0.1 M). The fat content was determined using the extraction system (Buchi, Switzerland) as follows: 3 g cheese samples were boiled in 50 mL HCl for 1 hour and filtered on filter paper; the samples were then dried at 75 °C (1.5 hours). Extraction of the sample in filter paper was carried out with 100 mL of petrol ether. The extraction program included extraction, rinsing, and drying (40-60 °C). After 1 hour, glass with petroleum ether was set in the dryer (90 min. at 75 °C), cooled in a desiccator, and weighed, and the % of fat was calculated. The ash content was determined by incinerating the 3 g cheese samples for 1 h at 550 °C.

Fatty acids analysis

The HRN ISO 15884:2002 method was used to extract FAMEs from the cheese samples; the reference for the FAMEs consisted of 37 FAMEs with purity ≥99 % (Restek, Pennsylvania, USA). First, a 100 mg cheese sample was dissolved in n-heptane (5 mL) in a tube, and 0.2 ml of KOH (methanolic solution) was added and vortexed (Vortexer, Grant Instruments Ltd, England) for 1 min. Then, 0.5 g sodium hydrogen sulphate was added and mixed after 5 min (the reaction time). The tubes were set in the centrifuge (Hettich Zentrifugen, Tuttlingen, Germany) at 2000 rpm for 3 min (room temperature), while an aliquot of ester solution (clear supernatant) was set in a gas chromatograph Agilent 7890B (Agilent, Santa Clara, USA). The carrier gas was N2 with a split ratio of 20/1; the inlet pressure was 35.81 psi (225 °C), the total flow was 28.2 mL/min, and the column flow was 1.2 mL/min. FA separation was achieved using a fused silica-capillary column (Rt-2560), bis-cyanopropyl polysiloxane (not bonded) with length of 100 m, an internal diameter of 250 µm, and 0.2 µm film thickness (Restek, Pennsylvania, USA). The oven temperature was 100 °C (4 min), and heated to 240 °C (11 min), with a ramp of 3°/min. The volume of the injected sample was 1 μL with a detector temperature of 250 °C and a flow (N2) of 45 mL/min. The detector temperature was 250 °C and produced a flow (N2) of 45 mL/min. The total proportion of short-chain fatty acids included C4:0-C8:0, the medium-chain fatty acids included C12:0-C16:0, and the long-chain fatty acids included C18:0-C22:6.

The atherogenic index (AI) and thrombogenic (TI) index, as well as the health-promoting index (HPI), of the cheese was calculated based on the FA proportions in the cheese made from goat milk (Ulbricht & Southgate, 1991; Chen & Liu, 2020):

Statistical analysis

The average values for the chemical composition and FA proportions for the cheese were obtained for each group of goats and were analyzed using PROC GLM and the following model: Yijk = μ + fi + sk + fsik + eijk; where μ is the overall mean, fi is the effect of goats´ feeding (i = CONT, HSC-60, HSC-120), sk is the effect of lactation stage (k = 1-3), fsik is the interaction between feeding and lactation stage, and eijk is the residual error. Tukey's honestly significant difference test was used to compare mean values between groups, while p<0.05 indicated significance and p<0.10 indicated a trend. The values of the correlation coefficient (r) between certain FAs and the health indices of cheese were determined using Pearson´s correlation coefficients, where 0.00-0.19 indicated a very weak correlation, 0.20-0.39 weak, 0.40-0.59 moderate, 0.60-0.79 strong, and 0.80-1.0 very strong, according to Soeharsono et al. (2020). All results were obtained by SAS 9.4®.

Results and discussion

No previous animal nutrition research has examined the effects of hempseed by-products, such as HSC, on the chemical composition and FAs of cow, sheep, or goat cheese. However, the study conducted by Ianni et al. (2020) analyzed the microbiota and volatile compounds of ripened cheese from cows fed diets enriched with hemp seeds. Generally, nutritional strategies for goats have not been researched in detail with regard to their effects on cheese quality, and especially FAs. Although some studies explain these dietary effects, it is difficult to conduct comparisons due to numerous technological differences between studies in the cheese manufacturing process. The proportion of FAs in cheese is strongly related to animal feeding and specific feeding stuffs that affect milk FAs. However, as reported by Buccioni et al. (2022), the cheese-making process plays an important role in the quantitative transfer of some functional FAs from milk into cheese, due to heat treatment and microbial activities.

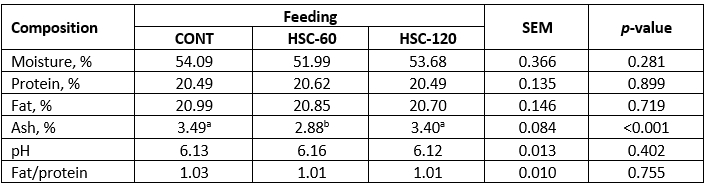

The chemical composition of goats´ semi-hard cheese was mostly unaffected by the goats’ nutrition being enriched with hempseed cake, as shown in Table 2. Feeding goats with HSC-60 significantly (p<0.001) decreased ash content compared to HSC-120 and CONT. Non-significant changes observed in the content of fat and protein in cheese, as affected by dietary treatment, can be explained by the isonitrogenous and isocaloric diets that have been formulated for lactating dairy goats. Lactation stage affected the moisture, fat, and ash content in cheese, while the feeding and lactation stage interaction affected moisture and ash content (Figure 1). It is commonly known that increasing milk yields causes a dilution of its components (Doran et al., 2021), which occurs in the early lactation stage and is reflected in cheese composition (Fig. 1). According to Coulon et al. (1998), in practice, the differences in the composition of cheeses made from mixed batches of milk are probably due to different feeding practices or health statuses, rather than technological practices.

Table 2. Chemical composition of semi-hard cheese from goats fed diets enriched with different amounts of hempseed cake

Means in the same row with different letters (a, b) differ (p<0.05). CON, control group without hempseed cake; HSC-60, concentrate mixture with 60 g/kg of hempseed cake; HSC-120, concentrate mixture with 120 g/kg of hempseed cake; SEM, standard error of the mean.

a, b - Means different letters differ p<0.05. S - stage of lactation, F - feeding.

Figure 1. Stage of lactation effect on the moisture, fat and ash content of semi-hard cheese made of milk from goats fed concentrate mixtures containing 60 g/kg of hempseed cake (HSC-60) and concentrate mixture with 120 g/kg of hempseed cake (HSC-120)

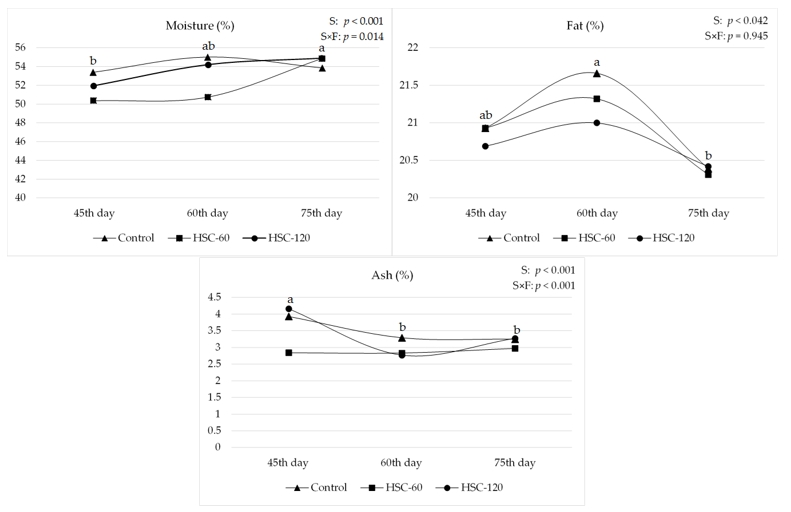

Table 3 presents the proportion of FAs in semi-hard cheese made from goats’ milk. The proportion of C8:0 in goats cheese increased in HSC-60 compared to HSC-120 and CONT (p<0.05), while C11:0 decreased in HSC-60 compared to HSC-120 (p<0.05). The proportion of C12:0 increased in HSC-60 compared to CONT (p<0.05), while it did not differ in HSC-120. The proportion of C13:0 in the cheese of the HSC-120 group increased compared to HSC-60, which was higher than CONT (p<0.05). The addition of HSC mostly had no effect on the proportions of individual SCFAs in cheese. Butyric (C4:0), caproic (C6:0), and caprylic (C8:0) acids are usually described as generally unpleasant, sweaty, rancid, and goat-like, but these FAs produce additional cheesy and sharp aromas that are highly desirable in cheese, contributing to its overall flavour and aroma (Qian & Burbank, 2007). However, in the study conducted by Ianni et al. (2020), in ripened cheese from cows fed diets enriched with 5 % (DM basis) hemp seeds, proportions of SCFA increased from C4:0 to C10:0, showing the prevalence of lipolysis during ripening. Dietary SCFAs may be a protective factor for human hypertension when higher levels are present in older adults (Gou et al., 2022) and may play an important role in maintaining the intestinal environment (Han et al., 2021).

Table 3. Fatty acid proportions in semi-hard cheese from goats fed diets enriched with different levels of hempseed cake

Means in the same row with different letters (a, b, c) differ (p<0.05). CON, control group without hempseed cake; HSC-60, concentrate mixture with 60 g/kg of hempseed cake; HSC-120, concentrate mixture with 120 g/kg of hempseed cake; FAMEs, fatty acid methyl esters; SEM, standard error of the mean.

The proportion of medium-chain fatty acids (MCFAs) such as C12:0 increased in HSC-60 compared to CONT, while C14:0, C14:1, and C16:0 increased in the experimental groups HSC-60 and HSC-120 compared to CONT. Palmitoleic acid (C16:1) increased only in HSC-60 compared to HSC-120 and CONT. The C17:1 proportion increased (p<0.05) in the goat cheeses of the HSC-120 group compared to the other groups. Stearic acid (C18:0) decreased (p<0.05) in the cheese of the experimental groups, as it was affected by dietary HSC. The FAs of cheese are strongly affected by the FA proportions in milk, which are transferred from the milk to the dairy products (Buccioni et al., 2022). The decrease in the proportion of C18:0 in cheese of experimental groups (p<0.05) may be related to the lower proportion of C18:0 in the concentrate mixtures of goats fed with HSC. Some of the C18:0 was possibly converted into oleic acid (OA, C18:1 c9; Griinari et al., 2000) by the action of the Δ-9 desaturase enzyme in the mammary gland, which was reflected in the cheese of the HSC-120 group having the highest (p<0.05) OA proportion compared to CONT and HSC-60. Rappeti et al. (2021) observed a similar increase in OA in the milk of goats fed hemp seeds in their diets, which reflects the pattern seen in the rumen. Higher level of biohydrogenation in goats´ rumen may have occurred in the HSC-120 goats, as evidenced in the higher proportion of LA isomers, such as C18:2 t9,c12, which are minor fatty acid metabolites produced from the biohydrogenation of LA in the rumen (Shingfield et al., 2010). Additionally, higher levels of OA and lower levels of C18:0 in dairy products may be the result of the biohydrogenation process in rumen, caused by different levels of fiber and PUFAs in the feed in which C18:0 is final product, which can be converted in OA in the udder. It was reported by Semwogerere et al. (2020) that HSC in the diet increases the retention time of rumen and improves the environment for microbial degradation in the rumen, thus affecting the conversion of PUFAs.

The proportion of ALA tended to increase (p=0.06) in the cheese made of milk from goats fed HSC-120. In a study conducted by Semwogerere et al. (2023), feeding goats with HSC up to 100 g/kg DM enhanced goat meat with n-3 PUFAs. Paczyk and Łuczynska (2020) determined an ALA range of 0.22-0.51 g/100g in hard goat cheese. In the present study, cheese was higher in ALA, with an increase of ~15 %, in the HSC-120 group compared to CONT. Moreover, feeding goats with HSC-120 increased γ-linolenic acid (GLA, C18:3 n-6) in cheese compared to HSC-60. The GLA is the first intermediary in the metabolic conversion of linoleic acid to C20:3 (c8,11,14 n-6) and then to arachidonic acid (ARA, C20:4 c5,8,11,14 n-6; Gunstone, 2003). As well as ALA, GLA is also highly important due to the anti-inflammatory and anti-cancer actions carried out by apoptosis and lipid peroxidation (Ge et al., 2009). As reported by González-Fernández et al. (2020), future in vivo experiments should focus on the possibility of using oils rich in ALA and GLA, which could be used as bioactive supplements for the prevention of colorectal cancer. Increased GLA in the cheeses of the HSC-120 group is the main reason why the proportion of ARA was slightly increased in this group. Juodka et al. (2018) determined that HSC contained 4.52 % of GLA, compared to camelina cakes or rapeseed cakes, which contained 0.11 or 0.06 %, respectively. However, in the present study, 3.20 % GLA was determined in HSC, thus affecting its proportion in goats´ cheese. As reported by Leizer et al. (2000), the presence of GLA in hemp seeds makes its nutritional value higher than that of other seeds.

The HSC-60 feed decreased the proportion of C20:0 compared to HSC-120 and CONT, while HSC-120 increased C20:1 c11 and C21:0 in cheese in comparison to HSC-60 and CONT. The proportion of C20:2 c11,14 (n-6) increased in the cheese produced by goats fed with HSC-60 compared to the HSC-120 and CONT groups; meanwhile, in both experimental groups, C20:3 c8,11,14 (n-6) increased compared to CONT. The proportion of ARA tended to increase (p=0.07) in HSC-120. Feeding goats with HSC-120 increased (p<0.05) docosahexaenoic acid (DHA, C22:6 c4,7,10,13,16,19 n-3) in semi-hard cheese compared to the HSC-60 group. The cheese from the HSC-120 group had ~26 % higher proportion of DHA compared to HSC-60; this is beneficial, since DHA in food may positively affect human health. The tendencies of ALA to increase and DHA to significantly increase in the HSC-120 cheese contributed to total n-3’s tendency to increase (p=0.05). The PUFAs, including LA and ALA, are essential nutrients. It has been already reported that ALA is converted to DHA and eicosapentaenoic (EPA, C20:5 c5,8,11,14,17 n-3) acid and that its conversion rate is modest (Huerta et al., 2016), so it is important to consume these FAs on a daily basis to maintain human health. These n-3 FAs are able to partially inhibit inflammation by inhibiting leukocyte chemotaxis, adhesion molecule expression, leukocyte-endothelial adhesive interactions, the production of prostaglandins and leukotrienes from the n-6 FAs, and the production of inflammatory cytokines (Calder, 2015). A similar increase in DHA and total n-3 proportions was determined by Antunović et al. (2021) in the musculus semimembranosus of lambs fed with 12 % HSC in concentrate mixtures.

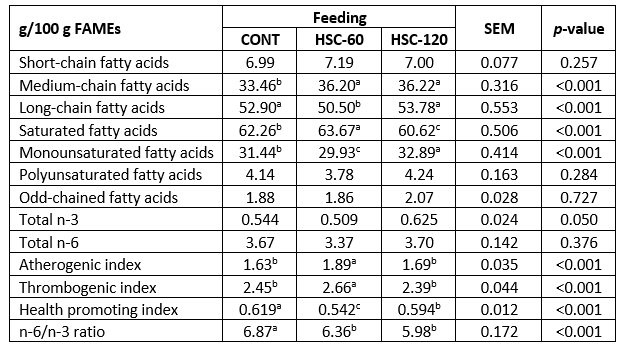

Table 4 shows the groups of FAs in semi-hard cheese made from the milk of goats fed HSC diets. The MCFA levels increased (p<0.05) in the experimental groups due to significant increases in C16:0; meanwhile, LCFA increased in HSC-120 compared to HSC-60 mainly due to C18:1 c9, which also increased MUFAs. The SFA increased in the HSC-60 group; these levels were followed by CONT and then by HSC-120, which were the lowest (p<0.05). The highest MUFAs were recorded in the HSC-120 group, followed by CONT and then HSC-60 (p<0.05). The total odd-chained fatty acids did not differ among groups, even though C11:0, C13:0, C17:1 and C21:0 were the highest in HSC-120. Although ALA did not increase significantly, together with DHA, it caused total n-3 FAs to tend to increase in HSC-120, which contributed to lowering of the n-6/n-3 ratio in HSC-120 by ~13 % compared to CONT. A lower ratio of n-6/n-3 FAs is beneficial in reducing the risk of many chronic inflammatory diseases present in Western society. It is known that hemp seeds have a beneficial n-6/n-3 ratio, which, in the present study, amounts to 3.9/1 for the HSC introduced to the concentrate mixture for goats, which contributed to its lower levels in semi-hard cheese made from goats´ milk. As reported by Rodriguez-Leyva & Pierce (2010), LA/ALA levels in hemp seeds are normally between 2/1 and 3/1; this has been proposed to be ideal for a healthy diet, as compared to the usual ratio of 20/1-30/1 in Western countries. The HSC introduced to the concentrate mixtures at 120 g/kg DM led to an appropriate AI and TI in the goat cheese, due to beneficial FA proportions (Table 4). However, in HSC-60, these indices were higher compared to the other two groups, possibly because of the lower proportion of MUFAs, specifically OA, and the lower total number of n-3 FAs. Indices in all groups were favourable as compared to Chen et al. (2004); in this review of dairy products, AI ranged from 1.42 to 5.13. Additionally, HPI was the highest in CONT, followed by HSC-120 and then HSC-60. Although HSC-120 has the highest proportion of beneficial FAs, including OA, DHA and MUFAs, or total n-3 and ALA, which tended to increase, the cheese from this group also contained higher proportions of C14:0 (r = -0.81) and C16:0 (r = -0.41), which lowered the HPI.

Table 4. Groups of fatty acids in semi-hard cheese from goats fed diets enriched with different levels of hempseed cake

Means in the same row with different letters (a, b, c) differ (p<0.05). CONT, control group without hempseed cake; HSC-60, concentrate mixture with 60 g/kg of hempseed cake; HSC-120, concentrate mixture with 120 g/kg of hempseed cake; FAMEs, fatty acid methyl esters; SEM, standard error of the mean.

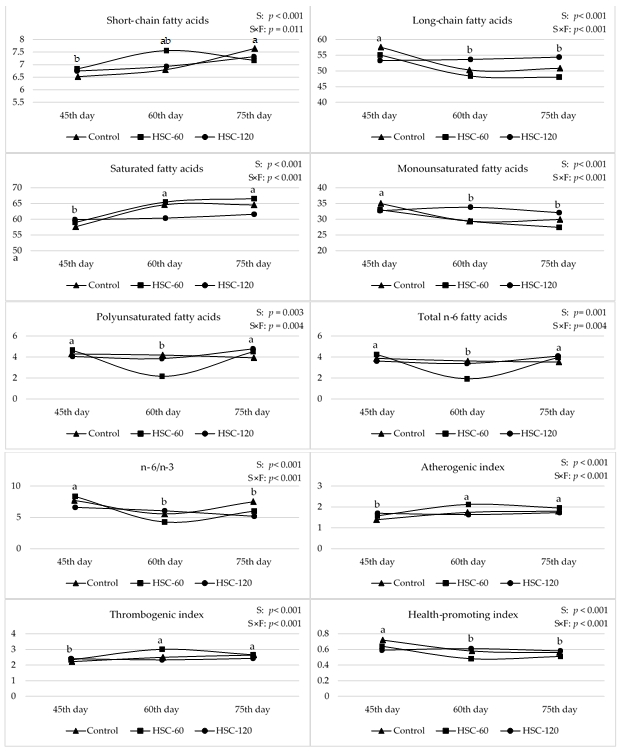

Figure 2 shows the significant effect (p<0.05) of lactation stage on the fatty acids’ groups in goats’ milk semi-hard cheese. The SCFAs increased on the 75th day of lactation compared to the 45th day, while LCFAs decreased after the 45th day of lactation, as was the case for the MUFA, HPI, and n-6/n-3 ratio. The SFAs increased after the 45th day, as did the AI and TI. The PUFAs were lower on the 60th day compared to the 45th and 75th days of lactation, as did total n-6. All of these proportions were significantly affected by the feeding and lactation stage interaction. After the peak lactation period, these fluctuations reflect the higher uptake of dietary FAs by adipose tissues (Chilliard et al., 1991), which usually occurs at 40–60 DIM, after which a negative energy balance occurs. These fluctuations in goats´ udders affect the milk, and consequently the FA proportions in cheese, which are reduced. Bittante et al. (2018) determined a decrease in OA, which is the main representative of MUFAs in cow’s milk, after the beginning of lactation. Since SCFAs and LCFAs are inversely correlated (Klir Šalavardić et al., 2022), SCFAs predictably increased from the 75th day.

a, b - Means different letters differ p<0.05; S - stage of lactation, F - feeding.

Figure 2. Stage of lactation effect on groups of fatty acids (g/100 g fatty acid methyl esters) and health indices in semi-hard cheese made of milk from goats fed concentrate mixtures containing 60 g/kg of hempseed cake (HSC-60) and concentrate mixture with 120 g/kg of hempseed cake (HSC-120)

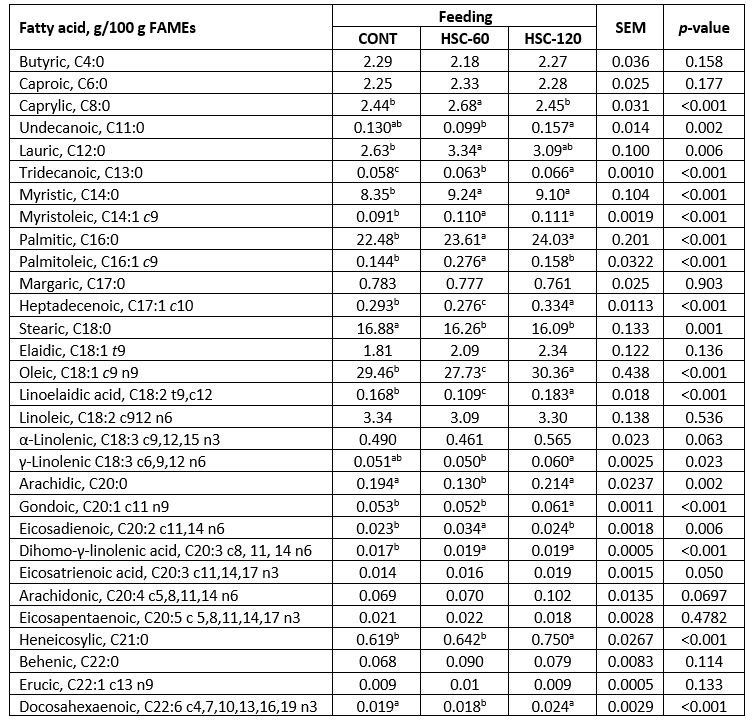

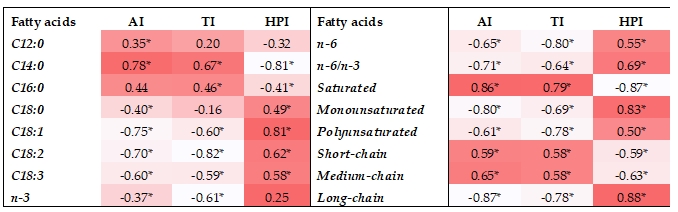

In Figure 3, correlations between certain FAs and health indices in cheese are presented. The C14:0 showed a very strong negative correlation with HPI, while C16:0 was moderately negatively correlated with HPI (p<0.05). The C12:0 had a weak correlation with AI only, while C16:0 only had a moderate correlation with TI; C14:0 was strongly correlated with both AI and TI (p<0.05). C18:0 had a moderate negative correlation only with AI, and a moderate positive correlation with HPI (p<0.05). All of the listed unsaturated FAs were positively correlated with HPI (p<0.05), as follows: LCFA, MUFA, and OA very strongly; LA and n-6/n-3 strongly; ALA, PUFA, and n-6 moderately; and were simultaneously negatively correlated (p<0.05) with AI and TI. The health indices, AI and TI, were mostly determined by the increase in C14:0; meanwhile, an increase in OA caused these indices to decrease, compared to the rest of FAs (Figure 3). The HPI of cheese mostly depends on increases in OAs and MUFAs, as can be observed from their very strong correlation in cheese.

Different intensities of colours between white and red indicate correlations from -1 to 1, respectively

Figure 3. Heatmap correlations between certain fatty acids and health indices (atherogenic index - AI, thrombogenic index - TI, health-promoting index - HPI) of semi-hard goat cheese (* indicates that correlations are significant at p<0.05).

Conclusions

Feeding goats with HSC-120 increased proportions of healthy fatty acids, including OA, GLA, and MUFAs. The introduction of HSC-120 into goats’ diets may have a contribution to the development of functional properties and higher nutritive value of semi-hard goat cheese compared to the cheese produced by goats fed with commercial concentrate mixtures. These findings may contribute to the development of value-added products for use in traditional cheese production on family farms.