Introduction

Salt (NaCl) is one of the most important ingredients in cheese production since it has a number of beneficial effects on cheese, including inhibiting the growth of pathogenic microorganisms, creating flavour and aroma, and increasing nutritional value (Guinee and Fox, 2017). Salt also has noticeable effects on starter culture and enzyme activity, cheese texture, ripening process, whey drainage and rind formation (Bisig, 2017). The amount of salt directly affects the texture of cheese. For example, cheeses without the addition of salt have a soft, doughy and sticky texture, while cheeses containing a larger amount of salt have a crumbly, dry and hard texture (Guinee and Fox, 2017). Furthermore, the amount of added salt is directly related to the amount of whey obtained, which ultimately has an impact on the cheese yield (López González et al., 2024). Three main salting methods are used in cheese production: dry salting of the curd grains, dry salting of the cheese surface and salting in brine (Havranek et al., 2014). Some cheeses, such are Domiati and Tallaga, are produced using the salting method, in which the salt is added directly to the milk before coagulation (Guinee, 2004; Arora and Khetra, 2017; Hayaloglu, 2017; Hamad and El-Deen, 2021). Although this salting method enables better salt distribution in the cheese, it also leads to prolonged coagulation and a lower firmness of the curd (Drgalić et al. 2002; Oštarić et al., 2023). Which of these methods is used in cheese production depends largely on the size, shape, type and ripening process of the cheese.

Apart from its influence on cheese production and quality, salt also has a significant impact on consumer health. Sodium (Na), one of the main components of salt, has several important functions in the human body, including the maintenance of nerve and muscle function, electrolyte balance, acid-base balance and osmotic pressure in cells (Aburto et al., 2013; Strazzullo and Leclercq, 2014). However, excessive dietary sodium intake can lead to health problems associated with high blood pressure (Ha, 2014; Feng et al., 2017), which is why the World Health Organisation recommends limiting salt intake in the diet to 5 g/day for adults (WHO, 2012).

Lički škripavac is an autochthonous cheese traditionally produced in some regions of Croatia, including Lika-Senj County and neighbouring towns. This cheese is categorised as a soft, full-fat, unripened cheese without rind. It is characterised by a white colour, a milky-sweet taste, a rubbery consistency and a squeaky sound when chewed. This sound is caused by the high temperature (over 41 °C) at which the curd grains are heated (Association of Small Cheesemakers of Lika-Senj County "Lički Škripavac", 2020). In addition to the high heating point of the curd grains, Škripavac cheese is also characterised by the salting methods used in its production. Traditionally, Škripavac cheese can be salted in two different ways: dry salting by adding salt to the curd grains after draining the whey and salting by adding salt to the milk before renneting (Zdanovski, 1947; Association of Small Cheesemakers of Lika-Senj County "Lički Škripavac", 2020).

Due to the aforementioned multifunctional role of salt in the quality of cheese, the results of this study will contribute to knowledge about the role of the salting method in the formation of the characteristics of this type of cheese, which is limited. Therefore, the aim of this work is to determine the influence of salting of milk and salting of cheese grains on the chemical composition, yield, texture and sensory properties of Škripavac cheese.

Materials and methods

Production of Škripavac cheese

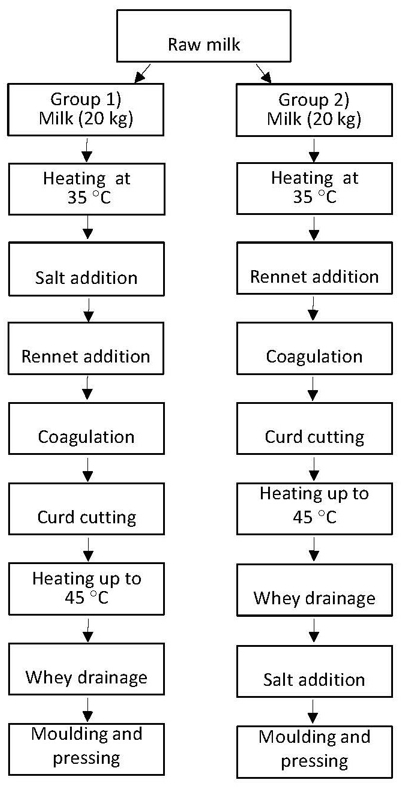

The milk for cheese making was collected five times from the farm located close to Zagreb and stored in a cooling tank at 4 °C before cheese making. Five batches of Škripavac cheese were produced in the pilot plant of the Department of Dairy Science at the University of Zagreb Faculty of Agriculture (Croatia). Each batch of Škripavac cheese was produced from 40 L of raw whole cow milk. The above mentioned quantity of milk per batch was divided into two equal parts of 20 kg each, from which two groups of cheeses with different salting methods were produced: I) by adding 3 % NaCl (~600 g) directly to the milk before adding rennet (group 1), II) by adding 1.5 % NaCl (~300 g) to the curd grains (group 2) which is shown in Figure 1. The fine sea salt from island of Pag (Croatia) was purchased from local market.

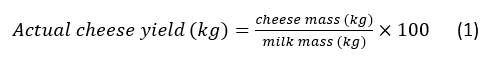

The raw milk was first heated to a temperature of 35 °C, then the milk was salted (in the case of group 1). For coagulation, rennet powder (Caglificio Clerici, Sacco, Italy) with a strength of IMCU 1170 was added to the milk. Rennet in the amount of 0.8 g was previously activated (dissolved in 50 mL of distilled water at room temperature for 10 minutes) and added to warm milk while stirring for 3 minutes. After the coagulation time (about 50 minutes), the curd was cut into hazelnut-sized (about 3 cm3) curd grains using a cheese harp (Figure 2). The curd grains were gradually heated to a temperature of 45 °C for 20 minutes under constant stirring. The curd grains were left at this temperature for further 10 minutes, after which the whey was drained off. At this point, salt was added to the curd grains in group 2 and mixed well (Figure 1). The curd grains were filled evenly into cylindrical plastic moulds, where they were gently pressed for 1 hour. The cheeses were stored in the refrigerator (4-8 °C) until further analyses were carried out (Association of small cheesemakers of Lika-Senj County “Lički Škripavac”, 2020).

Figure 1. Flow-chart of Škripavac cheese production

Figure 2. The appearance of the curd grains in the making of Škripavac cheese

Physicochemical analysis of milk and cheese

The physicochemical analysis of milk and cheese was carried out in the Reference Laboratory for Milk and Milk Products of the Department of Dairy Science at the University of Zagreb Faculty of Agriculture. The chemical composition of milk was determined prior cheese production by infrared spectrometry using the MilkoScan FT 120 analyser (FOSS, Hillerød, Denmark) (HRN ISO 9622:2001). The chemical analysis of the cheese was carried out after each production and included the determination of the fat content using the Van Gulik butyrometric method (HRN ISO 3433:2009), the protein content using the Kjeldahl block digestion method (HRN ISO 8968-1:2014), the total solids content by drying at 102 ± 2 °C to constant mass (HRN ISO 5534:2008) and the salt content using the potentiometric titration method (HRN ISO 5943:2007). Regarding the physical properties of cheese, the pH value was determined using the potentiometric method (Mettler Toledo, Seven Multi portable pH metre, according to the manufacturer’s instructions) and the water activity using the HygroPalm HP23-AW-A analyser (Rotronic AG). The content of moisture in the non-fat substance (MNFS) is calculated by subtracting the fat and expressing the moisture as a percentage of what is left.

Cheese yield, fat and protein recovery

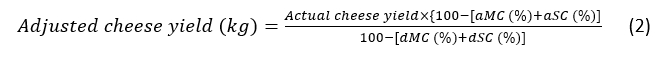

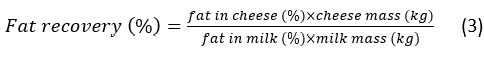

The actual and adjusted cheese yields were calculated using the following equations (Kalit et al., 2021):

where aMC is the actual moisture content in the cheese, aSC is the actual salt content in the cheese, dMC is the desired moisture content in the cheese (49 %), dSC is the desired salt content in the cheese (0.87 %).

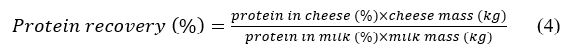

The percentage of fat and protein recovery was calculated using the following equations (Kalit et al., 2021):

Texture analysis

The textural properties of the cheese were analysed at the Institute for Adriatic Cultures and Karst Remediation in Split. The cheese sample for texture analysis was taken from the centre of the cheese parallel to the direction of pressing over the entire depth of the cross-section using a sterile cork borer (17.40 mm diameter). Before sampling, the cork borer was lubricated with paraffin oil to facilitate cutting out the samples. Approximately 1.0 cm of the surface of this sample was discarded, the remainder was used to obtain samples for texture analysis. Two cylindrical samples (height 25 mm, diameter 17 mm) were cut from the original sample using wire cutter. These samples were wrapped in plastic film and stored at 4 °C for the next 24 hours. Before the cheese samples were analysed, they were allowed to reach room temperature.

Texture measurements were performed according to the manufacturer's instructions using the texture analyser (TA Plus; Lloyd Instruments, Fareham, UK) equipped with a 500 N load cell (XLC -0500-A1; Lloyd Instruments) and a round aluminium compression plate (ST 6/1-50 mm; Lloyd Instruments). To avoid friction, compression plate was lubricated with mineral oil. Two cylindrically shaped samples were subjected to uniaxial compression by plate at a constant crosshead speed of 50 mm/min. After reaching the pre-test load of 0.01 N, the compression plate was moved until the moment when the sample fractured and then retracted to the zero position. Three textural parameters were evaluated using the Nexygen Plus 3 software: fracture stress, fracture strain, elasticity and hardness. According to the software manual, fracture stress was defined as the force per unit area to which the force is applied, while fracture strain was defined as the ratio between the length of the sample at fracture and its initial length. Elasticity is calculated as the extension from the preload to the point of fracture.

Sensory evaluation of cheese

The sensory properties of the cheeses were evaluated in the Laboratory for sensory analysis of agri-food products according to the method ISO 8589:2007 by a group of eight trained sensory experts using the standard method for sensory analysis of milk and milk products (HRN ISO 22935-3:2009). The samples were presented to the panellists after coding so the panellists didn’t know how samples were salted. The cheese samples were assessed against a predetermined list of defects with an overall quality score. At least 0.25 points were deducted for each defect in sensory characteristics, depending on the intensity of the defect. The characteristics assessed were: appearance (maximum score 2), colour (maximum score 1), body (maximum score 2), cross-section (maximum score 3), odour (maximum score 2) and taste (maximum score 10), with the highest total score achievable being 20 (Kalit et al., 2005).

In addition to the standard method of sensory analysis of milk and milk products, the participants assessed the sensory properties of cheese using the hedonic method, in which eight rated the cheese on a scale of 1 (very poor) to 9 (excellent) for the following sensory characteristics: colour, odour, squeakiness and overall likeability.

Results and discussion

Physicochemical properties of milk and cheese

The production of Škripavac cheese can be performed with a milk with a fat content of at least 3.5 % and a protein content of at least 3.2 % (Association of small cheesemakers of Lika-Senj County "Lički Škripavac", 2020), and therefore the milk used for this research with a milk fat and protein content of 4.02 % and 3.51 % was appropriate. The pH value of the milk varied between 6.61 and 6.71.

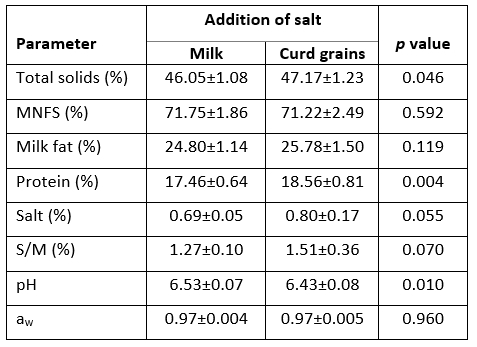

Table 1 shows the average values of the chemical composition and physical properties of cheeses that were salted by adding salt to the milk before adding rennet (group 1) and cheeses that were salted by adding salt to the curd grains (group 2). The cheeses in group 1 had a significantly (p<0.05) lower average total solids content (46.05±1.08 %) than the cheeses in group 2 (47.17±1.23 %). The most likely reason for this is the increased water binding capacity of the casein micelles, which results from the binding of sodium ions (Na+) to negatively charged kappa-caseins in the milk during milk salting (Elzeny, 1991). This is consistent with previous studies (El-Sissi and Shendy, 2001; Abd El-Gawad and Ahmed, 2011) showing an increase in the ratio of water to total solids in cheeses made from different types of milk as a result of increased water retention. In addition, the salting of the milk resulted in cheeses with a significantly (p<0.005) lower protein content (17.46±0.642 %) compared to cheeses with salted curd grains (18.56±0.810 %). Similar results were obtained by El-Sissi and Shendy (2001), who reported that an increase in the amount of salt added to buffalo milk before coagulation led to a decrease in the total nitrogen content of the cheese. In addition, Tratnik et al. (2000) and Hamad (2015) reported a lower milk fat content in Domiati cheese made from salted milk compared to salted curd grains in the production of Feta. In this study, similar differences in milk fat content were found between cheeses that were salted by adding salt to the milk (24.80 %) and cheeses in which the curd grains were salted (25.78 %), but these differences were not statistically significant (p=0.119). Considering that other studies (Tratnik et al., 2000; Hamad, 2015) have found a significantly lower milk fat content in cheeses where the milk was salted during production, such results could also be obtained for Škripavac cheese if a larger data pool was used.

Table 1. Chemical composition and physical properties of Škripavac cheese salted by different methods (n=5)

Results are expressed as mean ± standard deviation.

MNFS - moisture in non-fat substance, S/M - salt in moisture content, aw - water activity

Cheese that was salted by adding salt to the milk had a significantly (p<0.01) higher pH value (6.53±0.070) compared to cheese whose curd grains were salted (6.43±0.082). These results are in line with previous studies (Tratnik et al., 2000; Hamad, 2015), which found a higher pH of milk-salted Domiati cheese in contrast to a lower pH of curd grains salted Feta. This suggests that the addition of salt to milk prior to coagulation leads to an inhibition of microbial activity, especially that of lactic acid bacteria, which reduces acid production and consequently keeps the pH of the cheese high. In addition, the average water activity of cheese made by adding salt to milk was 0.97 ± 0.004 and of cheese in which production salt was added to the curd grains was 0.97 ± 0.005, making their differences insignificant (p>0.9), as most of the additional water was chemically bound to casein micelles.

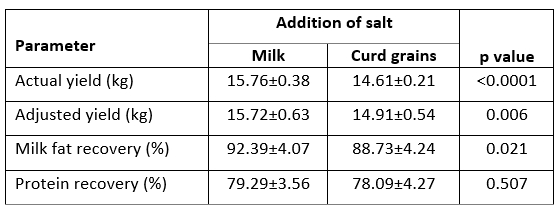

Cheese yield, milk fat and protein recovery

As shown in Table 2, the addition of salt to the milk before coagulation resulted in significantly higher actual (p<0.0001) and adjusted (p<0.01) yield (15.76 kg and 15.72 kg, respectively) than the addition of salt to the curd grains (14.61 kg and 14.91 kg, respectively). Similar results were reported by Abd El-Gawad and Ahmed (2011) and Tratnik et al. (2000), who obtained a higher yield in the production of milk salted Domiati cheese compared to curd grains salted Feta. The main reason for the higher cheese yield achieved by adding salt to the milk before coagulation is the increased water retention, which consequently increases the weight of the cheese. Another reason for the higher yield when making cheese from salted milk could be the slightly higher fat and protein recovery (Table 2). Table 2 also shows that the average milk fat recovery of cheese in which production milk was salted was 92.39±4.07 %, while the same parameter for cheese salted by adding salt to the curd grains was 88.73±4.24 %. On the other hand, protein recovery was 79.29±3.56 % and 78.09±4.27 %, respectively. While milk fat recovery was significantly higher when the milk was salted (p=0.021) than when the curd grains were salted, protein recovery was higher, but not statistically significant (p=0.507).

Table 2. Cheese yield, milk fat and protein recovery of Škripavac cheese salted by different methods (n=5)

Results are expressed as mean ± standard deviation

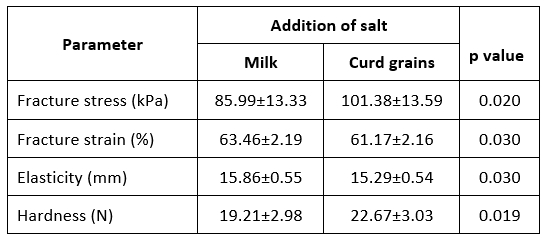

Texture of cheese

The salting method had a significant effect (p<0.05) on the textural properties of Škripavac cheese (Table 3). Our results show that cheeses made by salting of curd grains were significantly harder (p=0.019), less fracturable (p=0.020) and less elastic (p=0.030) than cheeses made with salted milk. The results presented in Table 1 show that cheeses salted by salting curd grains had a significantly (p=0.004) higher protein content than cheese made from salted milk. As is generally known, the paracasein matrix has the greatest influence on the mechanical properties of the cheese. The higher the casein content, the more numerous the bonds within and between the strands, which leads to greater resistance to deformation of the matrix. In addition, the mechanical properties of the paracasein matrix also depend on other milk components (moisture, fat, lactose and whey proteins) trapped in the spaces between the structure (Fox et al., 2017). Moisture occupies the spaces between fat and protein in the cheese structure and acts as a good lubricant due to its low viscosity (Gunasekaran and Ak, 2002). In contrast to moisture, fat acts as a lubricant or plasticiser depending on its physical state (Guinee and Law, 2002). The results of this study show that both cheese groups had quite similar values for moisture in the non-fat substance (MNFS) content, regardless of the salting method (Table 1). It can also be evident that the salting method had no significant effect on the fat content in either cheese group. The following facts support the conclusion that the moisture content in the non-fat components together with the fat content did not play an important role in the textural properties of both cheese groups. An explanation for the softer texture of cheeses made from salted milk compared to cheeses salted by salting curd grains could be related to the effects of the direct addition of salt to the milk before coagulation. Elzeny (1991) analysed in detail the important technological and functional properties of milk associated with the addition of salt prior to renneting. According to this study, the addition of salt to milk before renneting led to an increase in soluble calcium in the milk serum, an exchange of Na+ for Ca2+ bound to the casein, a change in micelle shape from spherical to irregular and an increase in micellar hydration of the casein. This led to a longer coagulation time, the coagulum formed is usually weak as both the number and the strength of the bonds between the casein micelles decreases and consequently the drainage of the whey is slowed down (Abd El-Salam and Alichanidis, 2004). On the other hand, the addition of salt to the curd grains increases the ionic strength in the water phase of the cheese and increases the solubility of the proteins (Pastorino et al., 2003; Floury et al., 2009). An increase in the salt concentration in the water phase of the cheese led to the paracasein network becoming more hydrated and swollen, resulting in a larger area occupied by the protein matrix. The consequence of this process is an increase in the hardness of the cheese (Pastorino et al., 2003).

Table 3. Texture of Škripavac cheese salted by different methods (n=5)

Results are expressed as mean ± standard deviation

Sensory properties of cheese

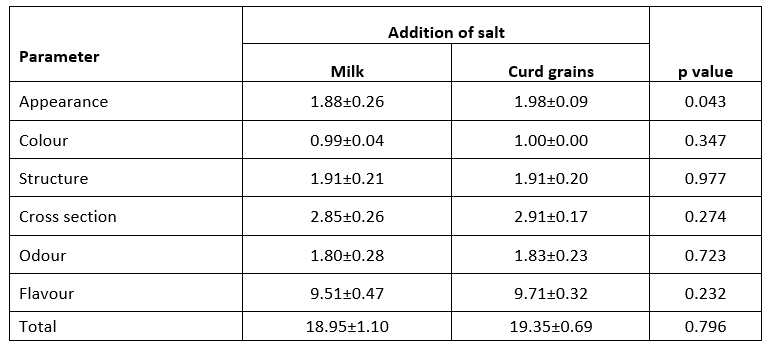

The sensory properties of cheeses produced by salting of milk and curd grains, which were evaluated by experts according to the standard method of sensory analysis of milk and milk products with the highest total score achievable being 20, are shown in Table 4. It was found that none of the sensory properties tested, with the exception of appearance, showed significant differences between these two groups of cheeses. Although there was no statistical significance, it can be noted that cheeses made with salted milk had equal or slightly lower average scores for the individual sensory attributes as well as for the total sensory score compared to cheeses made with salted curd grains. These results are consistent with previous studies, including Hamad (2015) and Tratnik et al. (2000), which found slightly lower sensory scores for Domiati salted in milk compared to Feta salted in curd grains.

Table 4. Sensory evaluation (standard method) of Škripavac cheese salted by different methods

(n=5)

Results are expressed as mean ± standard deviation

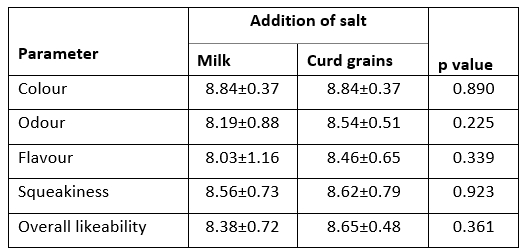

The acceptability of Škripavac cheese produced using two salting methods was tested using a hedonic sensory evaluate on 9-point structured scale where 1 meant “disliked extremely” and 9 meant "liked extremely" whereby the liking score of 7 or higher is usually indicative of highly acceptable sensory quality (Everitt, 2009). Sensory traits were evaluated: colour, odour, flavour, squeakiness and the overall likeability. The results presented in Table 5 show that there is no significant difference between Škripavac cheese where the milk was salted during production and Škripavac cheese that was salted by adding salt to the curd grains. It is important to mention that there were no significant differences in scores for the squeakiness, the most important sensory characteristic of Škripavac cheese, between these two groups of cheeses (p=0.923).

Table 5. Nine-point structured scale of hedonic sensory evaluation of Škripavac cheese salted by different methods (n=5)

Results are expressed as mean ± standard deviation, where 1 meant "disliked extremely" and 9 meant "liked extremely" whereby liking score of 7 or higher is usually indicative of highly acceptable sensory quality

Conclusions

The results of this study show that the salting method significantly affects some parameters of chemical composition, physical properties and texture of cheese. Briefly, the addition of salt to the milk led to the binding of sodium ions to the casein micelles, which increased their hydration capacity and consequently reduced the total dry matter of the cheese produced from this milk. Moreover, the addition of salt to the milk prior to coagulation inhibited acid production by non-starter lactic acid bacteria, which kept the pH value of the cheese higher. At the same time, higher water retention was associated with a higher cheese yield and a softer cheese texture. However, the method of salting has no significant effect on sensory characteristics particularly squeakiness when consumed. Thus it can be concluded that both salting methods are suitable for the production of Škripavac cheese, but in terms of yield, the milk salting method is better. Further research on the shelf life of the cheese could be helpful to make a final statement on the suitability of the salting method.

References

https://doi.org/10.3390/foods10040690

https://doi.org/10.3390/foods12122293

SAS (2015): SAS Studio University edition, 9.4.