Introduction

Fat in food industry contributes too many technological and palatability properties of final product like good texture, mouthfeel, flavor and taste. Mustard sauce is O/W emulsion like to mayonnaise where the oil phase is dispersed in continuous water phase, Also egg is the natural and unique emulsifier. Amount of oil in mustard sauce formulation is approximately half than mayonnaise this sauce is popular, especially in west countries. In recent years, most of people are interested to consummate popular food products like sauces and dressing with highest quality, valuable nutritional properties, palatability, and with low calorie and fat content. Especially because of some diseases such as obesity, hypertension and cardiovascular problems that demand the changing of food. The bad health effects associated with over consumption of certain types of lipids has led to a trend within the food industry to the development of reduced-fat products. It is a major challenge to produce reduced-fat foods which have the same appearance, stability, and flavor as their full-fat counterparts (McClements and Demetriades, 1998). A term of hydrocolloids has a wide array of functional properties in foods including; thickening, gelling, emulsifying, stabilization, coating and etc. Hydrocolloids have a profound impact on food properties. It has been reported that dietary soluble fiber such as β-glucan and guar gum decreases glucose and insulin responses to carbohydrates if taken in sufficient amounts and reduce total and LDL cholesterol, and probably also decrease the risk for cardiovascular diseases (Milani and Maleki, 2012). There is a various range of application of Inulin, Pectin and β-glucan in food production such as fat substitute, a thickening agent, and an emulsifier. This dietary fiber is used in the food industry in the production of dairy, sausage, salad dressing and cake filling and has ability to retain water and an oil-binding properties (Krapan et al, 2009;Mueller et al, 1995;Mansoiripour et al., 2014). At present time, there isn’t any study about low fat mustard sauce with added functional ingredients, such as fat replacers based on carbohydrate. On the other hand, the objective of the present study was to assess Pectin, Inulin and β-glucan as fat substitutes and their influence on physicochemical characteristics, and sensory properties of mustard sauce with dietary fibers.

Materials and methods

Raw Materials

All the ingredients used for preparation of the mustard sauce, such as whole egg, sugar, soy oil and vinegar were purchased from the local market, Tehran, Iran. Long-chain inulin ( 23 monomers, Frutafit Tex, Sensus, Netherlands), Kappa – carrageenan (CVT, China), Low- Methoxyl Pectin (Serda, Italy), Oat β-glucan (A.L.B, Sweden), Mustard powder (Colmens, England) were used also.

Inulin preparation

Specific amounts of inulin substance was suspended in water and mixed. After that, the suspensions were under heated till 80 ºC in water bath system for 9 min. After this step it was cooled to 25 ºC to form gel.

Treatments and mustard sauce formulation

According to (Table 1) ten treatments were evaluated to test fat replacement: control (T0); low fat with 2.5% of pectin (T1); low fat with 2.5% of inulin (T2); low fat with 2.5% of β-glucan (T3); low fat with of 5% pectin (T4); low fat with 5% of inulin (T5); low fat with 5% of β-glucan (T6); low fat with of 7.5% pectin (T7); low fat with 7.5% of inulin (T8) and lastly, low fat with 7.5% of β-glucan (T9). Each sample was composed of 1 kg of mustard sauce, and the analyses were performed in triplicate.

Preparation of mustard sauce

The control and low fat mustard sauce samples were formulated as shown in Table 1. In first step, gum (dissolved in hot water for 15 min), sugar, mustard powder and whole egg were mixed (Model 584, Teffal, France) and blended for 3 minute. In second step, oil was gradually added and blended for 6 min into the mixture until the emulsion system was established. In later step, after addition of vinegar, the mixture of all ingredients was blended for a further 5 min. The all of the prepared samples were kept in the refrigerator until the physicochemical and sensory analysis.

Chemical and physical analysis

The pH of mustard sauce was analyzed by pH meter (Metrohm, 744, Switzerland) at room temperature and water activity with AW Meter (Novasina, Switzerland). Meanwhile, acid value was measured by titration with NaOH solution.

Proximate analysis

The proximate analysis of the mustard sauce was performed after the preparation according to the AOAC (Association of Official Analytical Chemists, 1998) methods; moisture by method 950.46; ashes by method 920.153; fat by method 985.15. All the evaluations were performed in triplicate.

Color Measurement

Mustard sauce Color was measured by Hunter lab (Colorflex 450, USA) used to conduct L*(Lightness), a*(Redness) and b*(Yellowness) factors, meanwhile the equipment was calibrated before samples measurement. Color difference with respect to freshly made samples,(Eq.1), was calculated:

Texture Profile Analysis measurement

Mustard sauce textural properties measurement was carried out with the texture analyzer (Brookfield Ltd, CT3-1000, USA). Back extrusion cell with 35 mm diameter compression disc was used. The samples were carefully scooped into acrylic cylindrical containers (50 mm internal diameter and 57 mm height) to a depth of 55 mm. One cycle was applied, at a constant crosshead velocity of 1 mm/s, to a sample depth of 30 mm. From the resulting forcetime curve, the values for texture attributes, i.e. firmness, adhesiveness and cohesiveness were obtained using the Texture Expert for Window Version 1 equipment software.

Viscosity measurements

Full fat and low fat mustard sauce viscosity measurement were performed by viscometer (Visco88, Bohlin Ltd, UK) after 24 h storage at 25 ºC. Apparent viscosity was measurement at 100 s-1 shear rate.

Sensory evaluation

Sensory evaluation was conducted on the mustard sauce samples after one-day storage at room temperature by 9- point hedonic scale, 1= the least ; 9 = the most, the highest (Worrasinchai et al., 2006). Sensory characteristics including appearance, color, texture, mouth feel, taste, overall acceptance and intent to purchase were evaluated by 10 Professional trained assessors. Orders of serving were completely randomized water was provided between samples to cleanse the palate.

Statistical analysis

All the tests were performed in triplicate, and results were expressed as mean standard deviation. Comparisons among treatments were analyzed using the Least Significant Difference (LSD). Also, Treatments means were considered significant at (P < 0.05 .The result was performed using the SPSS version 18 windows program.

Results and discussion

pH

The pH value of FF and LF mustard sauce are shown in Table 2. There was no significant ( ) difference in pH values (3.80-3.78) of all LF formulation mustard sauce prepared with dietary fiber fat replacers. Moreover, the pH value decreased gradually in all of LF mustard sauce samples. The decrease in the pH values might be due to dilution acetic acid (vinegar) in continuous aqueous phase of LF formulation. These results agree withWorrasinchai et al. (2006). They reported that there were no significant differences in pH values between FF and LF mayonnaise. Therefore,Mendez-Zamora et al. (2015) stated that polysaccharides and proteins in food interact by attraction and repulsion between the polar and non-polar groups of polysaccharides and protein, resulting in pH fluctuations. These results are in consistent withMarinescu et al. (2011).

Acid value

Acid value of LF and FF mustard sauce are shown in Table 2. There was no significant ( ) difference in acid values (0.749-0.753) of all LF and FF samples after one day storage. All of Mustard sauce samples had gradually decreased in acid value with increasing level of fat replacers after one day storage. This decrease could be, attributed to greater water content that contained more microbial loading, which may be due growth of acid tolerance microorganism such as lactic acid bacteria like staphyloccuce aurous whose growth phase is often depended (Karas et al., 2002;Pourkomailian, 2000).

Physicochemical analysis

The composition analysis of chemical and physicochemical values of FF and LF mustard sauce with different ratios of fat replacers is listed in Table 3. The moisture value of LF mustard sauce was significantly (P < 0.05) increased by increasing level of fat substitution. The addition of dietary fiber based on carbohydrate increased moisture content. Similar behavior was found byAmiri Aghdaei et al. (2012) andHala amin et al. (2014) who added some fat replacers based on carbohydrate and reported that this fiber increase water hold capacity caused by ability and potential of hydroclloides to bind and holding water in their structure to form hydrogen bond with water molecules. In term of ash content, there is no significant (P < 0.05) difference between FF and LF samples. The fat content of the Lf mustard sauce was significantly (P < 0.05) reduce by increasing level of fat replacers. The water activity of LF mustard sauce samples gradually increased by increasing percentage of dietary fibers caused by water holding capacity and large number of hydroxyl groups.

Color attributes

The addition of dietary fiber had significant effect (P < 0.05) on the color parameters of mustard sauce (Table 4). The lightness (L-value) of all Inulin and Pectin samples were higher than control sample. Therefore, the L-value of LF mustard sauce prepared with β-glucan decreased with increasing level of β-glucan concentration.Mc clements (2005) reported that always samples with smaller fat droplet size and higher content of fat have high lightness. However, application of Inulin, Pectin and β-glucan affects the lightness, yellowness and redness parameters.

Textural profile analysis

The effect of replacing fat with different levels of dietary fat replacers on the textural parameters of mustard sauce was presented in Table 5. In addition, the results showed significant (P < 0.05) differences in textural properties. Firmness and adhesive were greatest and cohesive was lower with added fat replacers. These differences could be attributed to the fat content in emulsion and dietary fiber ingredients due to their uppermost binding ability and water holding capacity in formulation. Substantially, this result is caused by increasing the viscosity of the emulsion due to application of fat replacers based-on carbohydrate to prepared LF formulation. Worrasinchai et al. (2006) explain this behavior by the increasing the elasticity of the emulsion and crosslinking of polymer chains to form a three-dimensional network at continues phase by addition of hydroclloides. Similar result were obtain byAmiri Aghdaei et al. (2012a) who stated that low fat mayonnaise prepared by oat hull and Basil seed mucilage had higher adhesive and close firmness to control sample than those of other samples.

Viscosity analysis

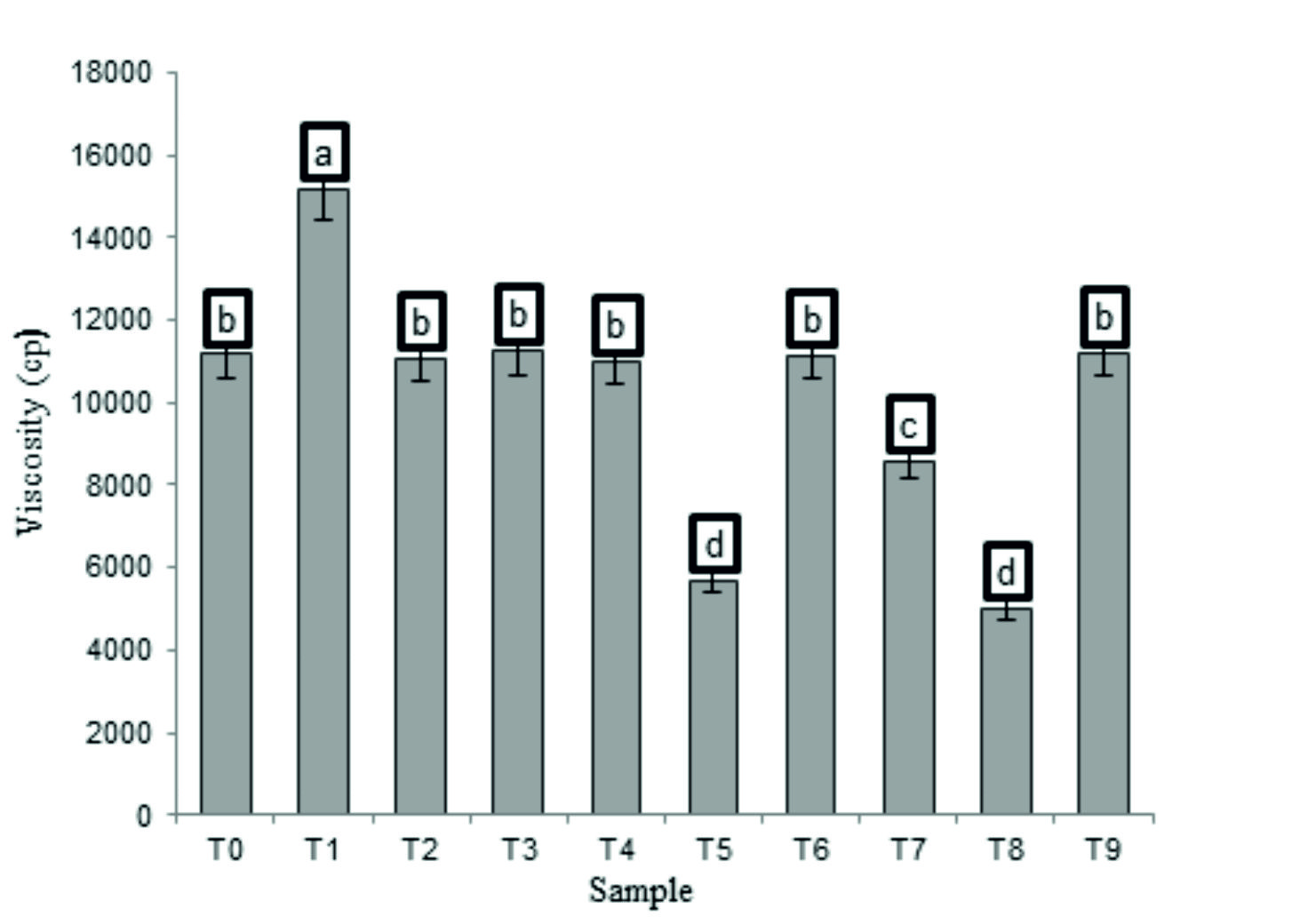

Undoubtedly, rheological properties such as flow behavior and viscosity of emulsions are completely dependent on droplet flocculation (Mc clements, 2005). The effect of different concentration of fat replacers used to prepared reduced fat mustard sauce on viscosity were also showed in Fig 1.

T0: Control, T1: Pectin25%, T2: Inlin25%, T3: β-glucan25%, T4:Pectin50%, T5: Inulin50%, T6: β- glucan50%, T7: Pectin75%, T8: Inulin75%, T9: β-glucan75%. %s. Values fallowed by same letter in each column are not significantly different at P < 0.05 by LSD test

It could be seen, the sample with 2.5% of pectin recorded higher viscosity than the other samples. The viscosity decreased by increasing of concentration of fibers, while the fat content was reduced to form the LF mustard sauce. In O/W emulsion, the large content surface area between oil droplets leads to important friction force, which oppose to the free flowing of the emulsion in a shear rate, hence increasing its viscosity. This shows that the reduction in oil content and the addition of water incorporated with dietary fibers has decreasing effect on this property.

Sensory evaluation of Full and reduced-fat mustard sauce

Sensory evaluation of LF mustard sauce samples compared with FF mustard sauce was presented in Table 6. The result showed that there were significant (P < 0.05) difference in sensory evaluation between reduced-fat mustard sauce samples and FF mustard sauce sample. Meanwhile, Mouthfeel was improved with Inulin ingredient; mouthfeel of T2 was higher than control one. On the other hand, amber color attribute of T3 treatment was better than other samples. Finally, the overall acceptability and intent to purchase showed that T0 and T3 acquired greatest scores.

Conclusions

So in conclusion, Pectin, Inulin and β-glucan are proper for fat reduction formulations in low-fat mustard sauce. Moreover, some parameters such as Intent to purchase, for low-fat mustard sauce with concentration level of β-glucan 2.5%, were highly evaluated. Meanwhile, some treatments, such as treatments with inulin and pectin at concentration level of 2.5%, acquired mark close to control sample. From these result, it could be concluded that all of fat replacers in this research can provide the reduction of oil content up to 25% in preparation of low-fat mustard sauce.