Introduction

With increasing consumer awareness in recent years that food has become very important for human health, which is accompanied with a renewed interest in improving the nutritional values of foodstuffs with proteins. Flour from leguminose (soy, chickpea, lupin and pea) and their protein isolates have been successfully used into formulations for high protein bread (Angioloni and Collar, 2012;Dhingra and Jood, 2002). The soybeans have a well-balanced amino acid composition therefore it makes an important source of plant protein. Pea is an important source of commercial proteins. One of the reasons why pea is used for commercial fraction of proteins more often than other pulses is that the former can be grown extensively all over the world and that its hull is easily removed. The increasing popularity of the usage of pea proteins largely results from their positive fat- and water-binding capabilities, emulsification properties and gelation as well as from their texture and nutritional values (Sandberg, 2011).

Wheat gluten is usually an important ingredient of formulations of protein-enriched bread (Day et al., 2006). It improves the texture and elasticity of dough, facilitates the retention of the gas and steam of baking, and gives more volume to baked bread (Georgopoulos et al., 2004). The aim of this study is to formulate wholemeal spelt bread enriched with protein preparations which originate from soy and pea and to evaluate their effect on the properties of dough and the sensory and textural properties of protein-enriched bread.

Materials and methods

The light was shed on the estimation of dough mixing properties. Dough samples were mixed with water at the constant speed of 63 rpm using a Newport Micro-Dough LAB mixer (Perten Instruments, Australia). All the dough samples had the same composition (Table 1). The amount of added water was determined as to achieve the dough consistency of 500 BU. Vital wheat gluten and soy protein concentrates were not used during the dough testing since it is well-known that vital wheat gluten strengthens dough (Msagati, T. A. M., 2012) and this would not reveal the real effect of soy protein isolates and pea protein isolates. The mixing parameters such as water absorption target (WAT), stability (S), arrival time (AT) and departure time (DT) were calculated using DLW version 1.0.0.56 software. The volume of the loaves was assessed by means of a Volscan profiler 600 laser measuring device (Stable Micro Systems, England). The specific volume was calculated on the ground of the volume and mass of loaves. Their basic chemical composition was determined in the following way: the protein (N × 6.25) content based on the Kjeldahl method, the crude fat content based on the Soxhlet method, the starch content based on the Ewers polarimetric method and the total reducing sugars content based on the Luff-Schoorl method.

The texture profile analysis of bread crumb was performed at the compression rate of 0.5 mm/s using a TA-XT2 plus texture analyser (Stable Micro Systems, England) according to a standard program. The sample of bread crumb taken from the centre of the 2 cm-high loaf was pressed by a SMS P/45 aluminium cylinder probe with the diameter of 4.5 cm to reach 60% deformation in two cycles with a 15-s delay. The resulting hardness, springiness, gumminess and chewiness of the crumb were used as indicators of textural changes. The calculations were made using Texture Exponent software (Stable Micro Systems, England). The appertaining analyses were performed after 24 h, after the baking and 4 replications.

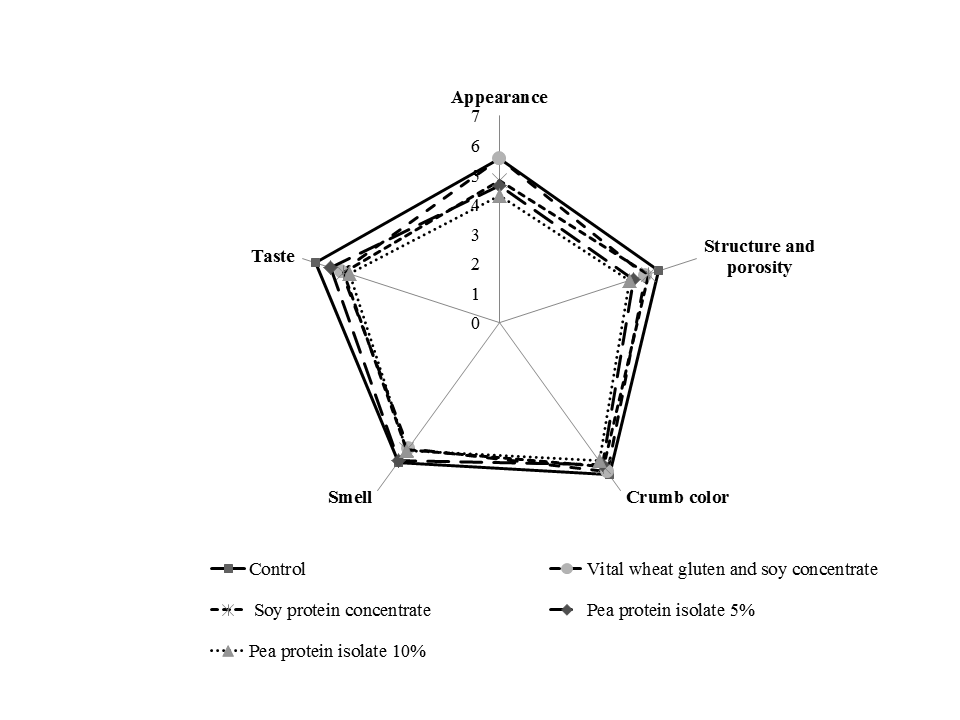

The sensory analysis of bread was performed by a panel consisting of six trained people. The analyses were conducted based on the method of acceptance analysis wherein the pre-coded samples were rated on a seven-point scale where 1 means extremely dislike and 7 extremely like. The panel considered the following quality benchmarks: appearance, structure and porosity, crumb colour, smell and taste.

The colour of the bread samples were measured using a Minolta Chromameter (Model CR-400, Minolta Co., Osaka, Japan) equipped with a glass protection tube CR-A33f, an attachment designed for measurement of soft samples. The colour values were expressed as L* (whiteness/darkness), a* (redness/greenness) and b* (yellowness/blueness), C* (chroma), and h° (hue angle). Each sample was measured in five replicates and the values were presented as means.

The analysis of variance (ANOVA) was based on one-way analysis of variance (statistical software Statistica 8.1; StatSoft Inc., Tulsa, Oklahoma).

Results and discussion

The effect of protein preparations on the mixing properties of dough

The dough with addition of protein preparations disclosed better properties during the kneading compared to the control dough, which can be seen inTable 2. Dough absorbs more water, which may result from the water absorptive capacity of soy proteins (Raidl and Klein, 1983). Furthermore, Sharma (2000) observed that water absorption increases significantly with an increased amount of pea. All that leads to an increase in the departure time. A longer departure time indicates stronger flour or a mixture of flour and other ingredients. The stability of dough supplemented with a soy protein concentrate was higher than that of dough with pea protein isolates. This behaviour of dough can be explained by the difference in the distribution of different classes of proteins in soybeans and peas. The major protein fraction in seeds of soybeans and peas involves albumins and globulins. Albumins are soluble in water and coagulatable by heat whereas globulins are insoluble in water but soluble in saline solutions. Unlike albumins, globulin proteins from plants contain relatively low levels of sulphur containing amino acids, cysteine and methionine. Furthermore, plant globulins are the bearers of emulsifying properties due to their much larger molecular size and structural constraint by disulphide crosslinks (Wong et al., 2012). The referring literature suggests that soybean contains approximately 90% of globulins while peas contain 50-60% of globulins and 15-25% of albumins, although the concentration of globulins can vary depending on different cultivars (Day, 2013). The stability of dough supplemented with soy proteins is higher than the stability of dough supplemented with pea proteins due to a higher concentration of the globulin in the soy protein structure.

*Water adsorption corrected for target peak resistance (500 FU).

**Departure Time - the required time for the top (maximum) curve to fall below the peak resistance.

***Arrive time - the time required for the top (maximum) curve to reach the peak resistance.

a,b,c – Different letters in a row denote a significant difference at p < 0.05 (Tukey HSD).

The effect of protein preparations on the chemical, physical and sensory characteristics of wholemeal spelt bread

The basic parameters that characterize the analysed bread are shown inTable 3. With respect to the control bread, partial replacement of wholemeal spelt flour enriched with proteins preparations caused a significant increase in the content of protein and a decrease in the content of fat and total carbohydrate. The increase in the protein content ranged from 40.25 to 85.70%. The highest growth was achieved with wheat, gluten, and soy concentrates, which is something that had been expected. The soy protein concentrate (20%) and pea isolate (10%) added to the spelt bread unveiled the same level of increase in protein (about 50%). The carbohydrate content is decreased and the greatest fall (by 30%) is recorded on the bread samples with soy and gluten. The formulation of bread per the current regulations can be declared to the high protein bread with reduction of carbohydrates, because it meets the requirements for high protein content and reduced carbohydrate content (paragraph 30 of National Regulations, 2013). The bread volume diminished due to the incorporation of these quantities of protein into the bread, but it was not so significant in the samples with vital gluten and soy concentrates as those with pea protein isolate (5%). Results inTable 3 show that a significant reduction of the bread volume is obtained with the participation of soy protein concentrate (on level 20%) and pea protein isolate (on level 10%). These samples had the lowest springiness, which is probably due to the smallest specific volume (Table 2) accompanied with the most compact structure.Nilufer et al. (2008) reported that poorly soluble soy protein added to bread significantly increases the bread hardness. The feeling in the mouth generated on the basis of chewiness and gumminess was the best in bread with vital wheat gluten and a soy protein concentrate while in other samples (except for 10% of the pea concentrate) these properties were on the level of the control sample. It is expected that bread with vital wheat gluten as a protein component in its composition shows the best physical and textural properties. What has also been noticed is a decline in the quality of bread with a higher intake of pea protein isolates. The level of substitution of 5% spelt flour with a pea protein isolate increases the protein content of bread to 40.25%, but the physical and textural quality is not reduced significantly. An interesting fact is that an intake of a 290% soy protein concentrate does not reduce much the quality of bread, which cannot be said for 10% pea protein isolates. This fact can be explained by the presence of different classes of proteins in soy beans and peas. Soy bean contains 90% of globulins, while pea contains 50-60% of globulins and 15-25% of albumins (Day, 2013;Wong et al., 2012).

a,b,c – Different letters in a row denote significant difference at p < 0.05 (Tukey HSD)

Crumb colour is an important factor for the acceptance or rejection of a product by consumers. The presence of various proteins modifies colour values in different ways (Table 4). In case of luminance L*, only the presence of soy protein does not significantly impact its value. However, with addition of pea protein (substitution level 10%) significantly lower L* values were measured, which means that they are characterized by a darker colour. The sample with vital wheat gluten and soy protein was characterized by the highest luminance of all samples. Parameter a* denotes the balance between green (negative values) and red (positive values). All samples have red hues because of the matrix (wholemeal spelt flour). As far as parameter b* is concerned, all the tested samples showed evidence of the dominance of yellow. The highest figures were measured with bread supplemented with vital gluten and a soy protein concentrate. The results show that the yellowness hue diminishes as the redness increases. It is clear that addition of plant proteins can change the acceptability of sensory attributes of bread (Paraskevopoulou et al., 2012). The results of the sensory analysis of bread supplemented with various protein types are shown inFig. 1. The poor acceptance of bread with pea protein isolates (10%) can be probably explained by its smallest specific volume (Table 2) accompanied with its most compact structure. However, significant differences in the appearance among breads with proteins of soy (20%) and pea (5%) have not been detected. The control bread and bread supplemented with pea protein emitted the most acceptable smell. The flavour acceptability was poorer with protein-enriched bread than with the control bread, but not significantly for specimens with pea protein (5%). Greater flavour acceptability was found with pea protein isolates comparing to samples with a soy protein concentrate. It can be said that the reason for different protein concentration is hidden in the applied preparations. The palatability of spelt bread decreases with the rising presence of a pea protein isolate.

a,b,c – Different letters in a row denote a significant difference at p < 0.05 (Tukey HSD)

Conclusions

Protein preparations derived from legumes improves the mixing properties of dough made from wholemeal spelt flour. This improvement is primarily related to its higher water absorption and greater stability. The textural properties of dough supplemented with soy and pea protein preparations were more favourable than those of the control sample of dough. Supplementation of bread with a pea protein isolate at the level of 5% does not have strong negative impact on the bread volume and physical properties of crumb. Bigger shares of a soy protein concentrate (20%) and pea isolate (10%) in spelt flour cause reduction of the loaf volume. The overall sensory acceptance of bread with pea protein isolate (5%) is better than the other estimated bread samples. Yet, there remains the confirmed fact that improvement of protein-enriched bread relates to vital gluten wheat. All studied parameters indicate that pea protein could be a promising alternative to soy preparations. Further studies in this context should try to merge soy protein and pea protein to create a special kind of bakery products enriched with protein.