1. Introduction

The production of Varaždin pumpkin seed oil in Varaždin County is a centuries-old tradition. According to the older historical records, it was stated that 150 years ago the residents of the village of Biškupec near Varaždin were engaged in growing pumpkins and producing pumpkin seed oil (Ozimec et al., 2020). The manufacturing production of pumpkin seed oil began in the middle of the 19th century, and the producers began to present it at various economic exhibitions. The only pumpkin seed oil, produced precisely in Varaždin County, was presented at the First Dalmatian-Croatian-Slavonian Exhibition, which was held in August, September and October 1864 in Zagreb. The producers were Baron Metel Barlabaševečki Ožegović from the village of Bela and Baron Juraj Rauch from the village of Martijanec, both from Varaždin County (Šuhaj and Devide, 1864). The industrial production of Varaždin pumpkin seed oil began in 1917 when the factory Prva varaždinska hidraulička proizvodnja ulja (First hydraulic oil production) was opened in Varaždin. The increased production of Varaždin pumpkin seed oil was possible due to the use of machines - peelers, which stopped the long process of peeling pumpkin seeds before processing, and the factory purchased the entire production of pumpkin seeds from the area of Varaždin County. In the Municipality of Vidovec near Varaždin, the production of pumpkin seeds and pumpkin seed oil has been going on for more than 100 years, and in 1936 the first oil factory that processed pumpkin seeds into pumpkin oil was opened in the area. Varaždin pumpkin seed oil is also a symbol of a cultural and historical heritage of this region. The coexistence of people and products was marked by all kinds of historical events happening over a long period of time (wars, diseases, politics, etc.). However, the tradition of producing pumpkin seed oil continued to pass on to new generations within small peasant farms. Nowadays, more and more farmers decide to cultivate pumpkins and produce pumpkin seed oil to meet the increasing demands of consumers. Austrian and Slovenian pumpkin seed oils carry the prestigious quality mark of the European Union for protected designation of geographical origin, while Croatian Varaždin pumpkin seed oil is protected at the national level, and is currently in the process of gaining protection at the European level (Balbino et al., 2022). Compared to the production of other vegetable oils, the processing of pumpkin seeds into Varaždin pumpkin seed oil is specific and different because it is obtained by a mechanical process and by using heat, without additives, which results in a high-quality oil with specific sensory properties. This research aimed to analyse the quality of Varaždin pumpkin seed oils, which includes the content of free fatty acids, peroxide value, insoluble impurities and the composition of fatty acids.

2. Materials and methods

Samples

The analysed samples were collected as part of the Alpe-Adria International Pumpkin Oil Exhibition and the Northwest Croatia Pumpkin Oil Exhibition in the period between 2014 and 2022, except for 2020, when, due to the pandemic caused by the Sars-CoV-2 virus, no samples were collected and the exhibition was not held. At the beginning of each year, fresh pumpkin oils were prepared for the exhibition. Pumpkin seed oil samples were delivered to the laboratory in dark glass bottles of 250 mL volume for chemical analysis. The samples were kept in a dark and cool place until analysis. The production area of Varaždin pumpkin seed oil, from pumpkin planting to oil extraction, covers the geographical area of the entire Varaždin County. A total of 168 samples of Varaždin pumpkin seed oil obtained by mechanical procedures with the application of heat were analysed.

Reagents

Isooctane, potassium iodide, potassium iodate, sodium hydroxide, potassium hydroxide, and hydrochloric acid were obtained from Fluka–Sigma Aldrich-Merck (Darmstadt, Germany), and diethyl ether, isooctane, acetone, petroleum ether, and methanol from JTBaker (Gliwice, Poland). Starch, n-hexane, methanol were obtained from Carlo Erba (Val de Reuil Cedex, France), acetic acid from Macron (Gliwice, Poland), sodium thiosulfate from Gram Mol (Zagreb, Croatia), and ethanol from TTT (Sveta Nedjelja, Croatia). Indicators thymolphthalein, alkyl blue and methyl orange were purchased from Riedel-De-Haën (Charllotte, USA), sodium sulfate from Kemika (Zagreb, Croatia), and standard solutions of fatty acid methyl esters from Restek (Food Industry FAME Mix, Restek, Bellefonte, USA).

Determination of free fatty acid content

The content of free fatty acids was determined by titrimetry according to the HRN EN ISO 660:2010 standard. Free fatty acids (FFA) are formed from triacylglycerols by cleavage of ester bonds by the action of the lipase enzyme, high temperature and moisture. The principle of determining free fatty acids is titration with potassium alkali of a precisely known concentration when free fatty acids are neutralized with the formation of potassium salts of fatty acids. The titration that takes place is determined by using an indicator that changes colour at the moment when potassium alkali neutralizes all free fatty acids. 5 g of a sample of homogenized pumpkin seed oil is weighed into a 250 mL Erlenmeyer flask. 50-100 mL of a neutralized solvent mixture (ethanol: diethyl ether 1:1) is added and the sample is dissolved, with gentle heating, if necessary. The solution is titrated with standard potassium hydroxide solution with constant stirring and the addition of a thymolphthalein indicator. The titration is complete when the addition of one drop of hydroxide solution causes a slight but definite colour change which remains stable. The result is expressed in milligrams of sodium hydroxide per gram of the sample, that is, as a proportion of oleic acid.

Determination of peroxide value

The peroxide value is determined by titrimetry according to the HRN EN ISO 3960:2010 standard. It is a method used to determine the degree of oxidation of vegetable oil that has formed during the storage period. The peroxide value represents the amount of those substances in the sample, expressed as active oxygen, that oxidize potassium iodide under certain conditions. 5 g of a homogeneous oil sample is weighed in an Erlenmeyer flask, which is previously washed with a mixture of glacial acetic acid/isooctane and dried with nitrogen, and 50 mL of a mixture of glacial acetic acid/isooctane (3:2) is added with gentle stirring. After that, 0.5 mL of saturated potassium iodide solution is added. The Erlenmeyer flask is closed and shaken gently for 60 seconds. 100 mL of demineralized water and starch solution is added, the cap is rinsed, everything is shaken and the titration of the released iodine with a standard solution of sodium thiosulfate (0.01 mol/L) with the starch indicator starts. The titration is complete when the addition of one drop of sodium thiosulfate (0,01 mol/L) causes a colour change from violet to colorless and this colour is maintained for at least 30 seconds. The peroxide value is expressed in mmol of active oxygen per kilogram of oil.

Determination of fatty acids composition

Fatty acids are the main constituents of oil, where they are present in free form or bound with trivalent alcohol glycerol to form triacylglycerols. Fatty acid methyl esters are determined according to the HRN EN ISO 12966:2:2017 standard by the rapid transmethylation process. The oil sample is dissolved in isooctane and a methanol solution of potassium hydroxide is added. It is, then shaken vigorously and left to stand at room temperature. After that, hydrochloric acid and methyl orange indicator are added and the mixture is shaken until the end point of the titration. After the precipitate settles to the bottom, the upper organic layer containing the methyl esters is pipetted off. Methyl esters prepared in this way are injected into a gas chromatograph with a flame ionization detector immediately after preparation. The fatty acid composition is determined on a CP-1177 gas chromatograph (Varian GC 3800), using a capillary column Zebron ZB FAME 30 mx 0.25 mm ID, film thickness of 0.20 μm (Phenomenex), split/splitless injector and flame ionization detector. The injector and detector temperatures are 240 °C and 260 °C. The temperature programme of the column and oven is set to 100 °C (2 min); 10 °C/min to 140 °C; 3 °C/min to 190 °C; 30 °C/min to 260 °C. Gas flows measured are nitrogen 25 mL/min, hydrogen 30 mL/min, air 300 mL/min. Injection volume is 1.0 μL. Fatty acids are identified by comparing the retention time of each fatty acid concerning those obtained in the FAME standard, and the result is calculated by the normalization method of the chromatogram peak areas. The result is expressed as a percentage share of an individual fatty acid in relation to the total content of fatty acids.

Determination of insoluble impurities

The insoluble impurities in the oil are mainly the remains of parts of the pumpkin seeds left after the process of roasting and pressing the pumpkin seeds. Separation procedures such as sedimentation or oil filtration are most often used to separate insoluble impurities. The method of determining the proportion of insoluble impurities is based on filtration of the dissolved sample under vacuum through a sintered crucible. 5 g of the oil sample is dissolved in 100 mL of petroleum ether and filteres through a filter crucible under vacuum. The flask and the crucible with the sediment are washed several times with solvent, followed by drying the crucible with the sediment at 105 °C until a constant mass is obtained. The content of insoluble impurities is expressed as a percentage (%).

Statistical analysis

All statistical analyses were made using the computer programme Statistica ver. 8.0 (StatSoft Inc., Tulsa, OK, USA). A statistical comparison of each analysed quality parameter over the years was made in relation to the latest data (2022), i.e. the influence of the year of production on the quality parameters was monitored.

3. Results

Based on the results obtained from the analysis, the mean values, standard deviation and ranges for each parameter over the years were determined (Table 1).

Table 1. Free fatty acids, peroxide number and insoluble impurities over the years

In all tested samples, the values for the proportion of free fatty acids were less than 1.0% of oleic acid, which is in accordance with the Codex Alimentarius (Codex Stan, 1999), which limits free fatty acids to ≤2%. The influence of the year of production on the proportion of free fatty acids was determined for 2017, 2018, 2019 and 2021 and compared with the latest results from 2022 (Table 2).

Table 2. Results of the t-test analysis - the influence of the year of production compared to the year 2022

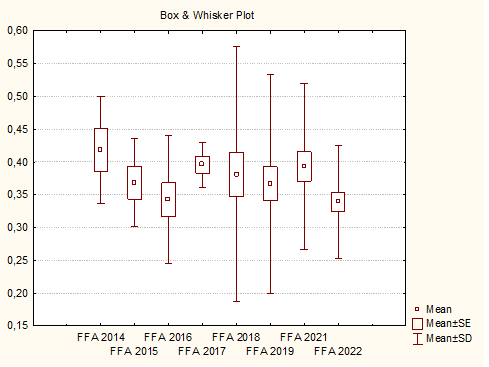

The values of free fatty acids were analysed (Figure 1) and it can be seen that the lowest mean values during the eight-year follow-up were recorded in 2022, while the highest values were recorded in 2014.

Figure 1. Mean values (%) and standard deviations for proportions of free fatty acids

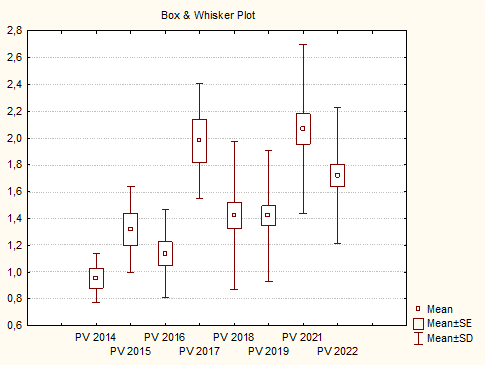

From the obtained results regarding the values of the peroxide value (Figure 2), the lowest mean values were recorded in 2014, while the highest in 2021.

Figure 2. Mean values (mmol O2/kg) and standard deviations of peroxide value

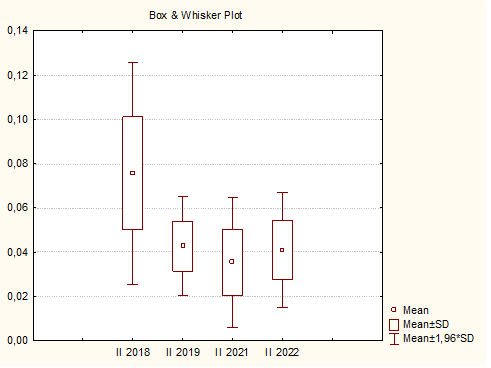

All measured values are less than 3.5 mmol O2/kg, which is in accordance with the Codex Alimentarius (Codex Stan, 1999), which limits the peroxide number to 7 mmol O2/kg. The influence of the year of production on the peroxide value was determined only for the year 2014 when (Table 2) and it was compared with the year 2022. It can be seen that the oils produced in 2014 had a higher oxidative stability. From the obtained results related to the analysis of insoluble impurities, it is evident that the lowest average values during the four-year monitoring were recorded in 2021, while the highest average values were recorded in 2018 (Figure 3).

Figure 3. Mean values (%) and standard deviations of the values of insoluble impurities

The fatty acid composition of Varaždin pumpkin seed oil was analysed throughout the observed period. Table 3 provides an overview of the results for each year for fatty acids that are prescribed by the national regulation.

Table 3. The composition of fatty acids in the analysed samples

The most abundant fatty acid is linoleic, and its range in the analyzed samples is from 31.6% to 54.64%, followed by oleic acid, whose share is between 28.44% and 49.67%. The share of palmitic acid is between 9.32% - 12.08% and stearic acid between 3.58% and 9.75%. All other fatty acids are present in an amount of less than 0.5%.

4. Discussion

Chemical indicators of the quality of Varaždin pumpkin seed oil that has been tested over the past eight years indicate a high quality of the oil that is constant throughout the years with minor variations, which are the result of specific climatic conditions occuring in the year of growing and harvesting pumpkins. The parameters that show the quality of the oil are the proportion of free fatty acids, ≤1%; peroxide value, ≤3.5 mmol O2/kg and insoluble impurities ≤0.05%. The oil also contains a high proportion of unsaturated fatty acids, ≥80%. This is supported by other studies and available literature data. In the results of oil analysis over three years of production, Neđeral et al. (2014) state that the quality of pumpkin seed oil is influenced by the climatic conditions of a particular production season. Based on the experience and knowledge of the manufacturers, the processing of the seeds into Varaždin pumpkin seed oil is carried out at lower temperatures, which results in the release of sweeter aromatic notes than those that would be achieved at normal frying temperatures. In addition, when preparing the dough from ground pumpkin seeds, smaller amounts of salt are added, which contributes to the special quality (Martinec et al., 2019). Previous research has shown that Varaždin pumpkin seed oil stands out for its basic standard quality parameters. Thus, in comparison with pumpkin seed oils produced in other areas of Croatia, Varaždin pumpkin seed oil produced in Varaždin County has the lowest multi-year average values for the proportion of free fatty acids and peroxide value, i.e., they are of better quality (Balbino, 2020). The influence of the year of production on the proportion of free fatty acids was determined for 2017, 2018, 2019 and 2021 and compared with the latest results from 2022. Such a result is a reflection of climatic conditions and is in accordance with previous tests when it was determined that a higher proportion of rainfall (moisture) in the growing and harvesting season of pumpkin is responsible for the higher proportion of free fatty acids due to the higher amount of moisture in the seeds, which increases the degree of hydrolysis (Neđeral et al., 2014). The higher the % of free fatty acids, the worse the oil and the degradation processes which are more intense and are regularly inversely proportional to the content of all other ingredients that make up its quality and nutritional value (Gotoh and Wada, 2006). Mean values measured for peroxide values vary from year to year. The peroxide number is closely related to the way the oil is stored, and fat oxidation is one of the basic reactions that affect the health of triacylglycerol because the products of the oxidation reaction are harmful to the health of consumers. Peroxide value represents the content of primary oxidation products in oils, and it changes during the ageing of the oil. It has been noticed that it becomes significant for the sensory evaluation of the oil 18 months after the production of the oil (Vujasinović, 2010). The data shows a significant decrease in the value of total impurities from 2018 to 2022. At the same time, 2018 was the first year of monitoring total impurities in Varaždin pumpkin seed oil as part of the evaluation of the oil for the exhibition. The mean value of insoluble impurities measured in that year exceeded the upper limit of 0.05% (Codex Stan, 1999). There is a significant statistical difference determined for the year 2018 compared to 2022. After 2018, education on the importance of adjusting the production process and oil ageing with the aim of reducing impurities in the final product was held for the producers of Varaždin pumpkin seed oil, which was effective. Already in the next year (2019), the proportion of impurities was significantly lower compared to the previous year (2018) and it remained so during the following years. The most abundant fatty acids in the analysed samples of Varaždin pumpkin seed oil are linoleic, oleic, palmitic and stearic. The average share of these four fatty acids in pumpkin oil is 98.08% ± 0.45%, which is in accordance with literature data (Murkovic et al., 1996; Neđeral et al., 2012). Only the two most abundant fatty acids, linoleic and oleic, were measured in larger ranges than those reported in the literature. Murkovic et al. (1996) state that the composition of fatty acids varies depending on several factors: variety, area of cultivation, climate and the stage of maturity of pumpkin at the time of harvesting. The formation of linoleic acid is achieved by direct dehydrogenation of oleic acid, while the formation of oleic acid is limited by kinetic parameters. Early harvesting (in the warmer part of the year) results in a decrease in desaturase activity. Pumpkin seeds that ripened for a longer period and were harvested later show a high proportion of linoleic acid (Neđeral et al., 2014). Therefore, a correction was made to the national regulation defining the requirements for the authenticity of pumpkin seed oil in terms of fatty acid composition in 2021. The proportion of saturated fatty acids in the analyzed samples is between 12.2% - 22.3%. The mean value of the proportion of unsaturated fatty acids in Varaždin pumpkin seed oil is 82.90 ± 0.6%; of that, the proportion of monounsaturated fatty acids is 28.5% - 49.9%, while the proportion of polyunsaturated fatty acids is in the range of 31.8% - 54.8%. The percentage of fatty acids in Varaždin pumpkin seed oil is slightly higher than what was stated in the research by Rezig et al. (2022), where the average value was around 74.61%. In general, the composition of fatty acids ranks Varaždin pumpkin seed oil among the most important sources of omega-3 unsaturated fatty acids, whose effect on health has been scientifically proven (Delaš, 2010). Pumpkin seed oil, i.e. Varaždin pumpkin seed oil, when produced traditionally, has recently been considered a functional food. It contains compounds such as polyphenols, phytoestrogens, and fatty acids that have been shown to exhibit positive effects on human health. Virgin pumpkin seed oil also contains various carotenoids, squalene, vitamins (tocopherols) and minerals that may also contribute to health aspects (Šamec et al., 2022).

5. Conclusion

Due to a long tradition, great effort and knowledge in soil cultivation, production and processing of seeds, as well as constant investments in knowledge and technology, the inhabitants of Varaždin County have been producing Varaždin pumpkin seed oil of the highest quality for decades. Apart from its characteristic colour and aroma, pumpkin seed oil also has a very high nutritional value and a positive impact on human health due to its composition. This study has shown a high quality of the Varaždin pumpkin seed oil that has been constant throughout the years. Basic chemical indicators of quality tested in this study were the proportion of free fatty acids, peroxide value and insoluble impurities. All of them were measured in low proportions, which is the best indicator of high quality. At the same time, the oils contain a very high proportion of unsaturated fatty acids. Variations in chemical indicators are under the influence of climatic conditions and production processes. Some 10-20 years ago, pumpkin seed oil was mainly produced for the regional market, but global consumer interest has turned the trend of use in a completely new direction. Virgin Varaždin pumpkin seed oil is still mostly used as salad oil or as an addition to bakery products. Moreover, the useful components found in the oils open up the possibility of using the oil as a functional food in the prevention and treatment of various chronic diseases. The inhabitants of Varaždin County are proud of their recognizable and valued product and of the producers, without whose effort, will and hard work they would not have the original product. New challenging times, the expansion of the market, and the increase in competition and production standards represent new requirements for producers, but also the possibility for the Varaždin pumpkin seed oil to compete with the European Union and the world due to its quality.

Author Contributions: Conceptualization: Dragutin Vincek; research work, analysis and interpretation: Dragutin Vincek and Melita Makovec; writing—original draft preparation: Valentina Vincek and Vesna Šimunić-Mežnarić: writing—review and editing: Dragutin Vincek. All authors have read and agreed to the published version of the manuscript.

Funding: This research received no external funding.

Conflicts of Interest: The authors declare no conflict of interest.