Introduction

Ice cream is a widely consumed frozen dessert, popular among all age groups due to its desirable sensory properties, nutritional value, and cooling effect. Generally, ice cream is composed of milk, sweetening agents, stabilizers, and emulsifiers. The physical structure of ice cream is a relatively complex three-phase system, where the unfrozen solution (liquid phase) contains distributed air cells, ice crystals, and fat globules (Goff, 2008).

Regarding consumer awareness of the impact of food on health and ice creams’ frequent presence in the human diet, it presents a good opportunity for the incorporation of numerous bioactive compounds in order to promote the health and benefits of functional food (Arslaner and Salik, 2020).

Turmeric ( Curcuma longa L.) is a plant from Zingiberaceae (ginger) family that is commonly used for culinary, food preservative, and colouring purposes. Except for its specific taste and colour, due to curcumin content, a wide spectrum of health benefits of turmeric has been claimed. It is reported that turmeric provides anti-inflammatory (Lüer et al., 2012), antioxidant (Priyadarsini et al., 2003), insecticidal (Attia et al., 2022), diuretic (Shalaby and Hammoda, 2014), anti-diarrheal (Owolabi et al., 2012), hepatoprotective (Tung et al., 2017), antidiabetic (Chuengsamarn et al., 2012; Zhang et al., 2013), antibacterial (Han and Yang, 2005), and anticarcinogenic (Aggarwal et al., 2003) effects. Despite of the healthy properties of turmeric, these beneficials have been hindered. Numerous studies have reported that curcumin exhibits poor bioavailability because of its chemical instability and rapid metabolizing in the liver and intestine. The methods for improving the bioavailability of curcumin have received considerable attention. Besides using its structural analogues, liposomal curcumin, curcumin phospholipid complex, or its encapsulation, an interesting approach to increasing curcumin bioavailability is its combination with piperine from black pepper (Hewlings and Kalman, 2017; Sharifi-Rad et al., 2020; Tabanelli et al., 2021).

Black pepper ( Piper nigrum), also known as "King of spices" belongs to the family Piperaceae (Milenković and Stanojević, 2021) . In addition to its flavour-enhancing properties, black pepper offers a range of health benefits owing to the content of bioactive compounds, among which the most important is piperine. It is reported that black pepper (and piperine) can provide anticancer, anti-inflammatory, antimicrobial, antioxidant, hepatoprotective, analgesic, and antidepressant activity, as well as protection against cardiovascular diseases (Newerli-Guz and Śmiechowska, 2022).

The impact of fortifying some dairy by adding turmeric powder has been investigated. Kumare et al. (2022) reported that the traditional Indian sweet made from milk, sugar, and nuts (burfi) can be enriched with 1.01 % turmeric powder and 0.90 % black pepper, without adversely affecting sensory properties. In the study conducted by Partio et al. (2023), the use of turmeric powder in concentrations of 0.9 %, 1.9 %, and 2.8 % as an antioxidant in milk was investigated. The increase in added quantity of turmeric powder led to an increment of curcumin content and antioxidant activity, while the hedonic value decreased. The study concluded that milk with 1.9 % turmeric powder was the most favourable in terms of results of the hedonic test and antioxidant activity. Rahmatalla et al. (2017) investigated the microbiological quality of set yoghurt supplemented with 0.25 %, 0.50 %, and 0.75 % of turmeric powder during storage. It was found that 0.75 % of turmeric powder significantly affected the microbiological quality of yoghurt. Guerra et al. (2022) reported the possibility of yoghurt enrichment with 1.0 % or 1.25 % gel-alike Curcuma longa suspension in function as a natural colourant. Although this enrichment did not impart pH and acidity, an increase in syneresis was observed. Chinazom Martina et al. (2020) explored the use of the aqueous extract of turmeric and the ethanol extract of turmeric, added before or after pasteurisation, in the preparation of yoghurt. The addition of turmeric extracts affected yoghurt colour, nutritional composition, and pH values. Furthermore, this enrichment caused a decrease in the microbial load of the yoghurt. Stirred yoghurt with 0.1 % turmeric added before fermentation exhibited the best sensory properties. The possibility of yoghurt fortification with turmeric was also reported by Seham et al. (2015) and Shalaby and Amin (2018). Turmeric was utilised in ghee production with improved nutritional characteristics, which resulted in a decrease in sensory acceptability with an increase in the level of turmeric powder (Amhore et al., 2020). Ranjan Singh et al. (2014) studied the effect of turmeric addition on the properties of fresh cheese type (paneer) prepared from cow milk, buffalo milk or mixed milk. They reported that turmeric addition extended the shelf life of paneer, and caused a slowdown in the chemical, microbial and textural changes during the storage.

However, to the best of our knowledge, there is a lack of reports showing the influence of the turmeric powder addition on the physicochemical parameters of ice cream. Thus, this research was designed in order to investigate the physical and chemical properties of turmeric ice cream, as well as ice creams with turmeric and black pepper powder. For this purpose, seven different ice cream formulations were manufactured: one standard, three turmeric-fortified, and three turmeric-fortified with the addition of black pepper. Ice cream samples were analysed for proximate composition, pH value, water activity (aw), rheological parameters, air incorporation level, fat destabilization degree, instrumental hardness, melting behaviour and instrumental colour.

Materials

UHT milk (2.8 % milk fat, Vindija d.d. Varaždin, Croatia), UHT cream (33.0 % milk fat, Dukat d.d. Zagreb, Croatia), skim milk powder (maximum 1.5 % milk fat, Dukat d.d. Zagreb, Croatia), sucrose (Viro d.d. Zagreb, Croatia), turmeric powder and black pepper (Nutrigold, Zagreb, Croatia) were supplied from a local grocery store. Soy lecithin was purchased from BDH Prolabo (VWR International GmbH, Darmstadt, Germany) and guar gum was supplied from Sigma-Aldrich, USA.

Ice cream production

Six ice cream formulations selected in the preliminary study (data not shown) and a control sample were prepared according to the formula specified in the text below, following a method described by Goff (2011), with slight modifications.

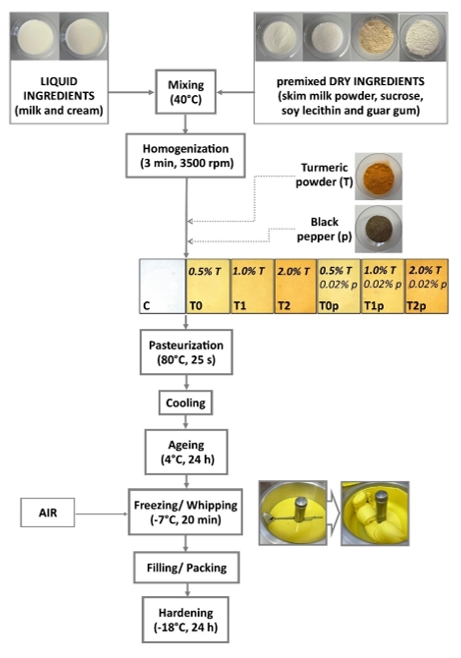

The manufacturing process of turmeric-enriched ice cream is shown in Figure 1. Firstly, milk (53.5 %) and cream (25.5 %) were heated to 40 °C. Afterwards, the previously mixed dry ingredients (5.5 % skim milk powder, 15.0 % sucrose, 0.3 % soy lecithin, and 0.2 % guar gum) were added to heated liquid ingredients and homogenized with IKA T 18 basic ULTRA-TURRAX homogenizer (IKA®-Werke GmbH & Co. KG, Staufen, Germany) at 3500 rpm for 3 min. The blended mixes were heated to 75 °C (except the control sample), turmeric powder at levels of 0.5 %, 1.0 % and 2.0 %, with or without 0.02 % of black pepper was added (for fortified samples) and pasteurisation at 80 °C for 25 s was conducted. Ice cream mixes were aged at 4 °C for 24 hours. Ice creams were made in an ice cream machine (GELATO 5K CREA i-Green, Nemox, Italy) at -7±1 °C for 20±2 min. During this process, the ice cream mix partially froze, and the surrounding air was incorporated through bending and mixing by direct entrainment from the agitator blades. After that, the ice cream was sealed in plastic bags, and hardened at -18 °C for 24 hours before the analysis.

Figure 1. Flowchart of ice cream production

Analysis of ice cream mixes

Physicochemical analysis

Total solids, protein, carbohydrates, and fat content were determined based on the standard procedures (AOAC, 2000). The pH of the ice cream mixes and ice cream samples was measured using a pH meter (WTW ProfiLine pH 3210, Wissenschaftlich-Technische Werkstätten GmbH, Germany). Water activity (aw) was measured using a HygroLab 3 Set (Rotronic AG, Bassersdorf, Switzerland) at 25±1 °C. The measurements were carried out in triplicates and the results are expressed as the mean values and standard deviations.

Rheological analysis

The rheological parameters were determined based on the method described by (Prindiville et al., 2000). The ice cream mixes after ageing were analysed using HAAKE™ Viscotester™ iQ Rheometers (Thermo Scientific™, Karlsruhe, Germany), equipped with coaxial cylinder measuring geometry (cylinder CC25 DIN/Ti). Ice cream mixes were loaded in the temperature-controllable cell to equilibrate to 4 °C. The measuring was performed at shear rates ranging from 0 to 300 s-1 and down from 300 to 0 s-1 at intervals of 6 s-1. The measurements were carried out in triplicates and the results are expressed as the mean values and standard deviations.

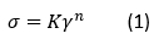

The consistency coefficient ( K, Pa sn) and flow behaviour index ( n) of the ice cream mixes were calculated according to the Ostwald-de Waele Model (Soukoulis et al., 2009):

where σ is shear stress (Pa) and γ is shear rate (s-1).

The apparent viscosity of the ice cream mixes was calculated at a shear rate of 50 s-1 (Kokini viscosity).

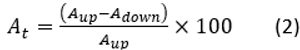

The hysteresis (thixotropic) areas ( At ) were calculated by the following equation:

Where Aup and Adow n are the areas (Pa/s) under ascending and descending flow curves (Kurt et al., 2016).

Analysis of ice creams

Determination of destabilised fat index

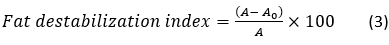

The fat destabilization index was determined according to (Goff and Jordan, 1989). Ice cream mixes and melted ice cream samples were weighed (3 g), and 27 mL of distilled water was added. An aliquot of these solutions (1 mL) was placed in a volumetric flask and diluted to 50 mL with distilled water. This 1:500 dilution was centrifuged for 5 min at 1000 rpm (Heraeus Multifuge 3SR Centrifuge, Thermo ScientificTM). After 10 min, absorbance at 540 nm was measured on a UV-spectrophotometer (Shimadzu UV-1280, Shimadzu, Japan), and distilled water was used as a blank. The measurements were carried out in triplicates and the results are expressed as the mean values and standard deviations. The percentage of fat destabilization was calculated by the following equation:

Where A is the absorbance of the diluted unfrozen mix and A0 is the absorbance of the diluted melted sample.

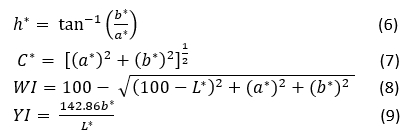

Determination of the overrun

Overrun was determined according to the method described by (Marshall et al., 2003), using the 100 mL cup. A known volume of ice cream mix and frozen ice cream were weighed, for every sample in triplicates, and overrun was calculated according to the equation:

Where w is the weight of the ice cream mix and w0 is the weight of the ice cream. The results are expressed as the mean values and standard deviations.

Instrumental texture analysis

Textural characteristics of the ice cream samples placed in 200 mL plastic containers were determined by the method described by (Surendra Babu et al., 2018), using a TA.XT Plus Texture Analyser (Stable Micro Systems, Great Britain) equipped with a 10 mm DIA CYLINDER DELRIN (p/10). The measurement conditions were set as follows: pre-test speed: 3.0 mm s-1, probe speed during the penetration: 3.3 mm s-1, post-test speed: 3.0 mm s-1, penetration distance: 15.0 mm, force: 5.0 g. Each sample was penetrated 7 times, and the results are expressed as the mean values and standard deviations.

Melting properties determination

Melting properties of ice cream samples were determined by methods described by Liu et al. (2022) and Nazarewicz et al. (2023), with slight modifications. The starting mass of each sample was measured. Ice cream samples (30 g) were placed on a wire mesh (6 × 6 mm). During the melting at ambient temperature (24±1 °C), ice cream was drained into a glass underneath the mesh, and dripped mass was measured at 10-min intervals for 60 min. The data recorded were used to determine the time of the first drop, percentage of melted ice cream, melting rate (%/min), and complete melting time. The melting rate was determined as the slope of the curve of the melted percentage as a function of the time (%/min). The measurements were carried out in triplicates and the results are expressed as the mean values and standard deviations.

Instrumental colour analysis

The L*, a* and b* values of ice cream mixes and ice cream samples were determined with a MiniScan WE colourimeter (Hunter Lab, Great Britain, MiniScan XE Plus) using the CIE-Lab colour space (CIE, 1976). Calibration of the colourimeter was carried out by using the standard black and white plate. The measurements were performed 10 times, and the results are expressed as the mean values and standard deviations.

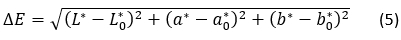

The overall colour change (Δ E) between the control sample and samples enriched with turmeric powder (and black pepper) was calculated by the following equation:

where L*, a*, and b* are values for the control sample, and L0* , a0*, and b0* for samples enriched with turmeric powder or with turmeric powder and black pepper (Lučan et al., 2020).

The colour indices, including the hue angle ( h*), chroma ( C*), whiteness index ( WI), and yellowness index ( YI), were calculated by the following equations:

The L*, a*, and b* values were used in the calculations (Pathare et al., 2013).

Data analysis

The data were analysed by ANOVA and averages were compared by Tukey Test at 5 % level of probability using XLSTAT software version 2019.2.2 (Addinsoft, New York, NY, USA). The relationship between the level of added spice, physicochemical and rheological properties of mixes and physical, melting and colour properties of ice creams was determined using Pearson’s coefficient of correlation (R2).

Results and discussion

Physicochemical properties of ice cream mixes

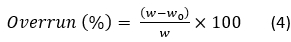

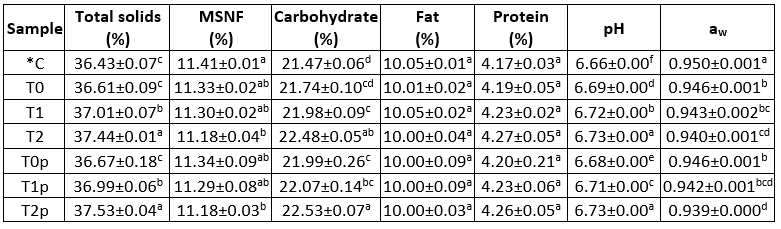

Chemical composition

Table 1 shows the proximate composition of the formulated ice creams. The main components in ice cream (fat, protein, carbohydrate, moisture) as well as incorporated air, can affect the physical and sensory properties of ice cream. There was a proportional increase in total solids and carbohydrates in all experimental samples with an increase in the proportion of added turmeric and black pepper powder compared to the control. The carbohydrate and total solid content were significantly higher in samples with higher amounts of turmeric (T1, T2, T1p, and T2p). Turmeric powder and black pepper have relatively low moisture content (Abdellatif et al., 2023; Majumder et al., 2021), so this could be the reason for an increase in the total solid content of enriched ice cream mixes. In terms of total solids (and carbohydrates), there was no significant difference between the series with and without black pepper.

Table 1. Physicochemical properties of different ice cream mixes

Data are expressed as mean ± SD. Means on the same column with different superscripts are significantly different using the Tukey HSD test (p<0.05).

*C-control sample; T0, T1, T2-samples with 0.5 %;1.0 % and 2.0 % of turmeric, p-samples with added 0.02 % black pepper. MSNF-milk solids non-fat.

There was no significant difference in protein and fat content between ice cream mixes. The change in milk solids non-fat (MSNF) ratio was found to be significant only in samples with the highest turmeric powder content (T2 and T2p).

pH and aw values of aged ice cream mixes

Opposite to a total solid content, aw values for all formulations decreased significantly with the increment of turmeric powder, as confirmed by Pearson's correlation test (Table 5).

The pH of ice cream is important to ensure ice cream mix stability. Too low pH is not desirable because it can impair ice cream texture or negatively affect its taste. On the other hand, too high pH can reduce the stability of the ice cream mix due to the protein solubility (Irawan and Fitriyana, 2021). According to Marshall et al. (2003), the average pH of the ice cream mix is between 6.30 and 6.50 and it is related to the composition of the ice cream mix. Changes in pH values of turmeric powder and black pepper enriched ice cream mixes and ice cream samples are given in Table 1. pH values of ice cream mixes were within the range of 6.66 to 6.73. The pH values of ice cream samples increased significantly by increasing turmeric concentrations. A similar trend was found in samples with black pepper addition. It was observed that samples T2 and T2p had the highest pH values, but there was no significant difference in pH values between those samples. Samples with black pepper addition had slightly lower pH values compared to those without it. The trend of increasing pH values by increasing turmeric content can be explained by the alkaline nature of turmeric (Buch et al., 2014). This agrees with a study reported by Chinazom Martina et al. (2020) who correlated the tendency to increase the pH value of yoghurt with turmeric extract addition. On the other hand, the addition of turmeric powder to soft cheese (Fareed and Al-Obaidi, 2019) or gel-alike Curcuma Longa L. suspension to yoghurt (Guerra et al., 2022) did not significantly affect pH values.

Flow behaviour characteristics of ice cream mixes

The rheological properties are related to flow behaviour during mechanical (stirring and flowing) and heat (pasteurisation and freezing) processing, as well as to the mouthfeel while consuming ice cream (Kurt and Atalar, 2018). A certain level of viscosity is essential for good whipping and retention of air, and for proper body and texture of the ice cream. Furthermore, the higher viscosity contributes to desirable mouthfeel (Goff and Hartel, 2013).

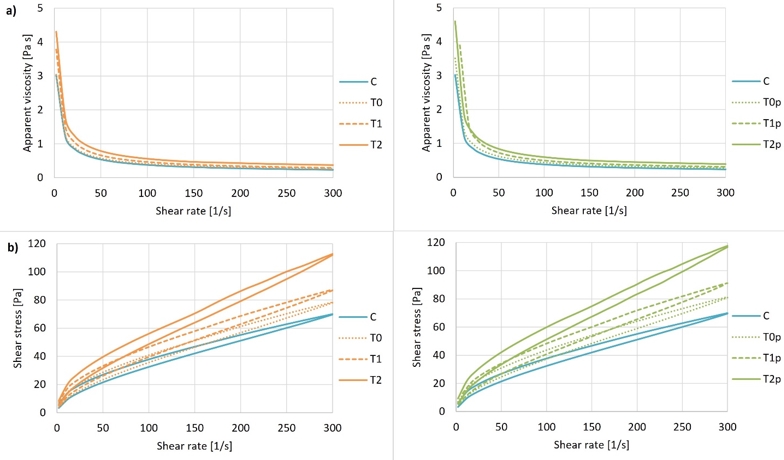

Figure 2. Viscosity (a) expressed as apparent viscosity (Pa s) and flow (b) curves (shear stress in Pa at different shear rates in 1/ s) of ice cream samples enriched with turmeric (T0, T1, T2 - samples with 0.5 %;1.0 % and 2.0 % of turmeric) and black pepper (p - samples with added 0.02 % black pepper compared to the control sample (C)

The changes in viscosity and rheological behaviours of the aged ice cream mixes are shown in Figure 2, and the rheological parameters of the Ostwald de Waele model (K and n value) and determination coefficient (R2) are presented in Table 2. All flow curves of the aged ice cream mixes showed good fits to the Ostwald de Waele model with R2 higher than 0.99.

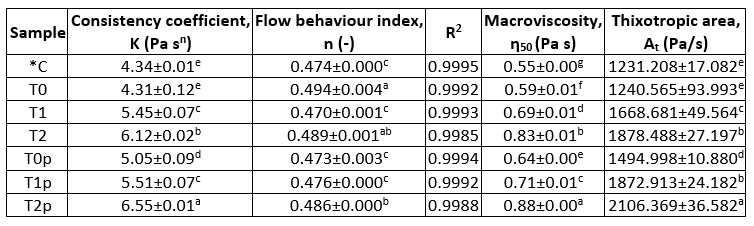

Table 2. Rheological properties of ice cream mixes

Data are expressed as mean ± SD. Means on the same column with different superscripts are significantly different using the Tukey HSD test (p<0.05).

*C-control sample; T0, T1, T2-samples with 0.5 %;1.0 % and 2.0 % of turmeric, p-samples with added 0.02 % black pepper.

Time independent rheological properties

The values of the flow behaviour index (n) were less than 1 (0.470-0.494) which indicates that all ice cream mixes are non-Newtonian pseudoplastic fluids. Ice cream generally exhibits shear-thinning (pseudoplastic) behaviour, as a result of the protein and carbohydrate macromolecules that are dispersed in solution (Goff and Hartel, 2013). As seen in Table 2, the control sample showed the lowest value for the consistency coefficient (K). The K values of fortified samples increased with increasing turmeric and black pepper proportion (4.31 Pa sn-6.55 Pa sn) indicating that a minimal addition of these spices to the mixes had a significant influence (p<0.05) on the rheological behaviour. Viscosity curves (Figure 2a) show that the addition of turmeric and black pepper resulted in increases in apparent viscosity. Kokini viscosity values at 50 s-1 (η50, Pa s) of the ice cream mixes are presented in Table 2. Macro viscosity calculated at Kokini shear rate of 50 s-1 represents the sensing shear rate upon oral processing of low-viscosity foods (Bourne, 2002). It can be seen that the turmeric and black pepper addition significantly (p<0.05) increased the Kokini viscosity. The highest Kokini viscosity value was obtained in the T2p sample. The control sample (C) as well as ice cream mixes with the addition of 0.5 % of turmeric powder, with and without the black pepper (T0, T0p), had the lowest values for macro viscosity. Such correlation between the increases in the apparent viscosity due to the addition of black pepper and cinnamon to ice cream was observed by Khawsud et al. (2020) and Aumpa et al. (2022). Yeon et al. (2017) found that enrichment of ice cream with fermented black pepper powder leads to its higher viscosity. Also, Partio et al. (2023) and Kumar Gaur et al. (2019) reported an increase in the viscosity of herbal milk due addition of turmeric.

Viscosity of the ice cream mixes is determined by many factors, including the addition of stabilizer, protein, fat and total solids content, the presence of macromolecules and some processing conditions (Goff and Hartel, 2013; Soukoulis et al., 2010). The higher viscosity value of fortified samples might be the result, except due to the higher total solids contents in mixes, from the presence of specific macromolecules in spices. Turmeric contains starches and other carbohydrates (Ikpeama et al., 2014) that have thickening properties and can increase the viscosity of the mix. On the other hand, piperine and essential oils from black pepper (Milenković and Stanojević, 2021) can interact with proteins and other components in the ice cream mix and thus can affect viscosity.

Time dependent rheological properties

All ice cream mixes demonstrated thixotropic behaviour as shown in Figure 2b with a hysteresis loop. Thixotropy can be defined as the time-dependent decrease in apparent viscosity with shearing (Goff and Hartel, 2013; Mewis and Wagner, 2009). This property is important to evaluate the relationship between structure and flow during processing in dairy technology, enabling the recovery of structure, again when the shear rate is eliminated or reduced. The thixotropic areas of samples are summarized in Table 2. The addition of spices significantly increased (p<0.05) the hysteresis loop, which indicated faster deformation, lower structure recoverability and more energy to eliminate the influence of time (Espírito-Santo et al., 2013). Only the difference in the thixotropy index between the control sample and sample T0 was found to be non-significant (p>0.05). Significant differences in the thixotropic behaviour have also been observed between samples with and without black pepper, with the same turmeric powder content (T0 vs. T0p; T1 vs. T1p; and T2 vs. T2p). These results suggest that the fluidity of ice cream mixes was affected by the presence of black pepper.

Turmeric addition had a significant positive correlation with coefficient of consistency, Kokini viscosity and thixotropy, as shown in Pearson’s correlation coefficients (Table 5). Moreover, a high positive correlation was found between the total solid contents and the index of viscosity (0.971), apparent viscosity (0.990) and thixotropy (0.934).

Overrun and fat destabilization of ice cream

Overrun

Overrun can be defined as an increase in ice cream volume due to the incorporation of air during the freezing. It is a very important property for determining ice cream quality because the air in ice cream provides its light texture and affects the melting behaviour (Goff, 2016).

The overrun values for ice cream samples are shown in Table 3. It can be seen that samples varied in overrun values depending on the added amounts of turmeric and black pepper powder, from 18.61 % in the control sample to 37.63 % in the T2p sample. The highest levels of overrun were found in a series of ice cream samples with black pepper supplementation. These values are similar to those obtained in ice cream with fermented black pepper powder (from 14.8 % to 20.3 %) reported by Yeon et al. (2017). However, these values are lower than the overrun values of ice cream reported in most literature. According to Ozdemir et al. (2008), Akalın et al. (2008), and Liu et al. (2023) it is difficult to achieve the volume increase of soft and semi-soft ice creams over 35-40 % during production in batch types of freezing machines. Nevertheless, the results of this research indicate that both, turmeric powder and especially black pepper increased ( p < 0.05) the amount of incorporated air.

Table 3. Overrun, fat destabilization index, hardness, and melting properties of ice cream

Data are expressed as mean ± SD. Means on the same column with different superscripts are significantly different using the Tukey HSD test (p<0.05).

*C-control sample; T0, T1, T2-samples with 0.5 %; 1.0 % and 2.0 % of turmeric, p-samples with added 0.02 % black pepper.

The amount of incorporated air depends on many factors. With the addition of turmeric powder, the total solids are increased, which can cause an increase in overrun (Qamar Abbas Syed et al., 2018). Besides, some researchers reported that overrun can be closely related to viscosity. The higher overrun for ice cream mixes with higher viscosity can be explained by more efficient air incorporation and the formation of smaller air cells during the freezing (Atik et al., 2021; Samakradhamrongthai et al., 2021). Similarly, the increase in overrun values in this study can be explained by the increase in viscosity due to the addition of turmeric and black pepper powder. Besides this, saponins from turmeric powder and some components of essential oils from black pepper have foaming properties and therefore may promote the formation and stabilization of air bubbles in ice creams (Ikpeama et al., 2014; Milenković and Stanojević, 2021). In our research, it was found a positive correlation (Table 5) between overrun and turmeric level (0.770), consistency coefficient (0.822) and macro viscosity (0.838).

Fat destabilization

The degree of fat destabilization is an important characteristic of ice cream, as it appears to influence the melting behaviour, stiffness, dryness and smoothness of the ice cream (Goff and Hartel, 2013). During whipping and freezing one part of the fat in the ice cream mix converts into aggregated fat that provides structural stability of ice cream by adsorbing to the surface of air bubbles creating a partially coalesced network.

The values for fat destabilization in this study ranged from 20.21 % to 57.20 % as shown in Table 3. In general, as turmeric powder content increased, the level of destabilized fat significantly (p<0.05) decreased. The control sample showed the highest level of fat destabilization while the lowest level was obtained for T2. Samples with black pepper addition (T0p, T1p, and T2p) also showed lower values of fat destabilization compared to the control sample, but higher compared to those without black pepper. This indicates that black pepper also influences the degree of fat destabilization, but contrary to turmeric, increasing it.

Many factors, including emulsifier type and shear stress, ice crystal size, and air cell content affect the extent of fat destabilization (Amador et al., 2017). Bolliger et al. (2000) reported that the fat destabilisation index depends on the shear forces increased by high viscosity, the overrun content and the extent of ice crystals. However, in our study, we found the reverse correlation: samples with higher spice addition had higher viscosity and higher overrun, but an unexpectedly lower degree of fat destabilization. This is in accordance with results reported by (Liu et al., 2023) where samples with higher overrun show a lower degree of fat destabilization, depending on the emulsifier type. In our study, the emulsifier remains the same in all samples. However, curcuminoids and saponins from turmeric possess emulsifying properties, which can contribute to fat stabilization in ice cream and thus can reduce fat coalescence. Furthermore, black pepper contains volatile compounds, such as monoterpenes and sesquiterpenes, which can interact with the fat globules in ice cream, affecting their stability (Ikpeama et al., 2014; Milenković and Stanojević, 2021).

Since no significant correlation (Table 5) with other examined properties of the mixes and ice creams was found in this study, a more comprehensive research is needed to understand the impact of turmeric and black pepper supplementation in ice cream on fat destabilization.

Texture of ice cream

The hardness of ice cream presents a resistance to deformation induced by external force. It is an important quality parameter of ice cream, as it directly influences the scoopability of the ice cream (Clarke, 2004), a factor of great significance for consumers' acceptability.

Influence of spice supplementation on the hardness of ice cream

In this study, the enrichment of ice cream mixes with powdered turmeric and black pepper had an impact on the hardness of the resulting ice creams. Both series of flavoured ice cream samples, either with turmeric powder or with turmeric and black pepper mix, showed significantly (p<0.05) lower hardness compared to the control ice cream sample (Table 3). The hardness values were the reverse of the overrun values, what is in agreement with the results reported by Muse and Hartel (2004), Pereira et al. (2011), and Biasutti et al. (2013). The standard ice cream showed the highest levels of hardness (13156.12 g) and the addition of turmeric decreased hardness to values in the range of 6810.26 - 11182.66 g. An even greater decrease in hardness was observed in the black pepper series, where values ranged from 4148.26 to 6539.76 g. Similarly, (Khawsud et al. (2020) found that a mix of black pepper and cinnamon decreased the hardness of ice cream samples, and Yeon et al. (2017) also found that black pepper ‑supplementation causes a decrease in the hardness values of ice cream.

Influence of physical properties on the hardness of ice cream

Hardness is affected by several factors such as melting point, total solids, ice crystal size, ice phase volume, extent of fat destabilization, overrun, and amount and type of stabilizer (Marshall et al., 2003). In our study, a strong negative correlation between hardness and black pepper addition (-0.793), coefficient of viscosity (-0.810), macro viscosity (-0.772) and overrun (-0.907) were observed (Table 5).

The rheological properties of the ice cream mixes had a large impact on the ice cream hardness in this study. Higher viscosity and denser structural network of fortified ice cream mixes could reduce the formation of large ice crystals during freezing, which can reduce the hardness of ice cream. This is similar to the results of Wang, Li, et al. (2022), Wang, Wang, et al. (2022), and Kurt and Atalar (2018) where higher viscosity in ice cream mixes with the addition of soybean oil and quince seed, led to harder ice cream.

Muse and Hartel (2004) found that ice creams with higher overrun and lower levels of destabilized fat tend to be softer, as indicated by our results. A larger amount of incorporated air along with higher viscosity, can lead to the formation of slightly smaller air bubbles and ice crystals, due to higher shear stress during freezing. However, some researchers (Peng et al., 2018) have obtained contradictory results that increased overrun leads to increased hardness of ice cream. This effect may have been related to the different sizes of air cells and ice crystals in ice creams.

The hardness of ice cream is also depending on the aggregate fat network. Aggregated fat can adsorb to air cell surfaces and develop a structural network that increases stability and thereby increases the hardness of ice cream. Contradictory results have also been observed for hardness and fat destabilization in ice cream, probably also due to secondary effects such as the ice crystal size and the ice phase volume (Liu et al., 2023).

Melting behaviour of ice cream

Melting behaviour has a great significance for consumer acceptability of ice cream. Neither fast-melting ice creams nor ice creams that melt too slowly are desirable for consumers (Goff and Hartel, 2013; Marshall et al., 2003). The melting of ice and the collapse of the fat-stabilized foam structure occur when ice cream is exposed to the ambient temperature.

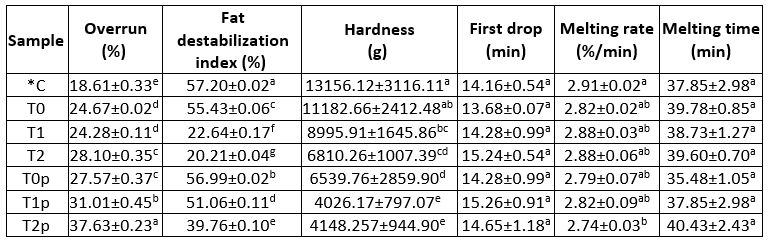

Figure 3. Melting curves (% of meted ice cream over 60 min) of ice cream samples enriched with turmeric (T0, T1, T2 - samples with 0.5 %;1.0 % and 2.0 % of turmeric) and black pepper (p - samples with added 0.02 % black pepper) in comparison to the control sample (C)

As shown by the sigmoidal curves in Figure 3, all ice cream samples had a similar meltdown behaviour. During the melting process, three phases can be identified: the lag phase, the fast melting phase, and the stationary phase (Wu et al., 2019). In the lag phase, heat enters the sample, and ice crystals start melting and diluting the serum phase so a decrease in viscosity occurs. The fast melting phase starts when ice cream, by force of gravity, starts dripping through a wire mesh to reach the maximum meltdown rate. The melting rate (%/min) is calculated as the slope of fast melting phase. The stationary phase represents the phase after complete ice cream melting.

First dripping time, melting rate and complete melting time

The time until the first drop was for all samples equally (13.68-15.26 minutes, Table 3), since it is weakly affected by the internal structure of the ice cream, but mostly depends on the surface properties of the ice cream and the amount of frozen water (Koxholt et al., 2001). According to the results of this study (Table 3), it is found that the melting rate in the fast melting phase decreased from 2.91 %/min (for the control sample) to 2.82 %/min for the sample with the addition of turmeric powder. Furthermore, the addition of black pepper further decreased the melting rate of ice cream samples (2.74-2.82 %/min), but the only significant difference according to Tukey’s post hoc test (p<0.05) was found between the control sample and T2p, sample with the highest level of spices. All samples were completely melted under 41 minutes (35.48-40.43 min) leaving only residue on the screen (Figure 3). Although the fortified samples had a slightly prolonged melting time, complete melting of the samples did not show any significant difference by ANOVA (Table 3). These results are in agreement with those reported by Yeon et al. (2017) and Trivedi et al. (2014) who investigated the effect of fermented black pepper powder and basil powder on ice cream properties. Conversely, Aumpa et al. (2022) found that mix of dried black pepper and cinnamon powder increased the melting rate.

Influence of physical properties on melting behaviour of ice cream

The melting rate is related to the air content (overrun), fat cluster size and proportion, ice crystal size and rheological properties of ice cream, but most significantly to the fat destabilization level (Goff and Hartel, 2013; Muse and Hartel, 2004).

Javidi et al. (2016), Kurt and Atalar (2018) and Muse and Hartel (2004) reported that more viscous ice creams melt more slowly. This is consistent with the results of our research, where ice creams with the addition of turmeric powder had a higher viscosity and a higher melting resistance.

Except for the above, overrun values can also affect the melting properties of ice cream . The melting rate of our samples was inversely correlated with the overrun values with a correlation coefficient of –0.832 (Table 5). This can be explained by the insulating effects of air bubbles and the interaction of air bubbles with the fat agglomerates, which slows down the melting rate by providing resistance to collapse (Sofjan and Hartel, 2004;Warren and Hartel, 2018).

The results of the melting properties of ice cream samples might be explained in terms of different fat destabilization degrees. In our study fat destabilization rates of turmeric enriched ice cream samples, are directly proportional to their melting rates. This is contrary to a study conducted by Muse and Hartel (2004), who reported that fat destabilization had the largest effect on the melting rate of ice cream samples and that the melting rate generally decreases as the level of fat destabilization increases. However, a direct correlation between fat destabilization and melting rates cannot always be observed, since the melting rate is influenced by a number of structural factors (Goff and Hartel, 2013). In the present study, the high viscosity of ice cream mixes fortified with turmeric and black pepper, and higher overrun in those samples, even if they have lower fat destabilization content than the control sample, may have been responsible for retarded meltdown. Muse and Hartel (2004) found that larger ice crystals significantly increase the rate of meltdown. Although the size of ice crystals was not measured in this study, it is possible that with the addition of turmeric and black pepper powder, additional particles were introduced into the ice cream matrix, which, along with increased viscosity and higher shear stress, can affect the formation and growth of ice crystals.

Overall, an inverse correlation was found (Table 5) between the melting rate and the black pepper addition (-0.785), and overrun (-0.832). However, it is difficult to define a relationship between different structural elements and ice cream properties. Further investigation is required to get more insight into the extent to which the composition and properties of fortified ice cream may affect the physical structure and melting behaviour of ice cream in this study.

Influence of black pepper supplementation on melting behaviour of ice cream

Interestingly, observing the individual melting intervals on the melting curve (Figure 4b), it can be observed that a series of samples with black pepper had a higher initial meltdown rate at the beginning of the melting process (interval 10-20 min) with a higher proportion of melted ice cream. At a later stage, they melted significantly more slowly and eventually melted the longest.

Liu et al. (2023) found that such a phenomenon (two-stage melting process) occurs in ice creams with an ice crystal-dominated microstructure, where higher overrun induced a loss of connectivity between ice crystals causing earlier melting in the first stage, and then in the second stage, a higher overrun slows down the melting process.

This phenomenon was more noticeable in a black pepper sample with a lower proportion of turmeric (T0p), which may indicate that turmeric and black pepper have the opposite, or at least, a different impact on the rate of melting. However, to completely understand this complex phenomenon, further research is needed.

Colour of ice cream

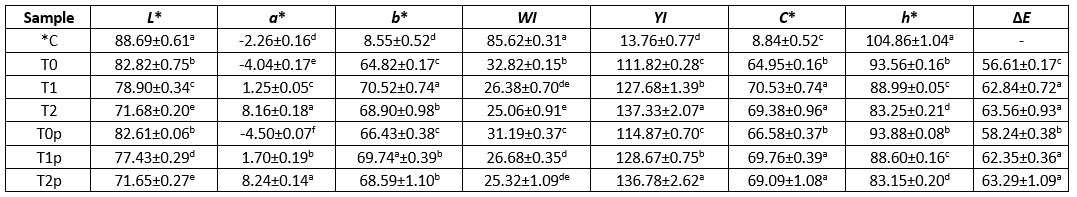

Colour is an essential parameter affecting the initial consumer acceptability of the food product (Salihu et al., 2023). Turmeric powder and black pepper are used as spices, improving the aroma and flavour of food, and curcumin, an intense yellow-orange natural colourant from turmeric, as a food additive (E100). The results of the colour measurement of control and flavoured ice creams are presented in Table 4. As expected, the addition of turmeric powder to ice cream samples significantly (p<0.05) affected all measured and calculated colour parameters.

Table 4. Colorimetric parameters of ice cream

Data are expressed as mean ± SD. Means on the same column with different superscripts are significantly different using the Tukey HSD test (p<0.05).

*C-control sample; T0, T1, T2-samples with 0.5 %;1.0 % and 2.0 % of turmeric, p-samples with added 0.02 % black pepper.

L* values represent the lightness of colour (0 = black, 100 = white), a* values colour ranging from redness (+120) to greenness (-120), and b* values from yellowness (+120) to blueness (-120) (Lukinac et al., 2022). L*, a* and b* values of control ice cream prepared without turmeric and black pepper were found to be 88.69, -2.26, and 8.55, respectively. As the turmeric powder concentration increased, lightness values significantly (p<0.05) decreased. A similar, but higher decreasing trend on L* values was observed in a series of samples with black pepper. As expected, lightness values in samples with black pepper (71.65 to 82.61) were lower compared to those without black pepper with the same turmeric proportion, ranging from 71.68 to 82.82. On the other hand, a* and b* values were generally significantly (p<0.05) increased with increasing the turmeric powder content, indicating changes from slightly green to slightly red, and slightly yellow to strongly yellow, respectively. Similarly, the redness and yellowness of turmeric-black pepper ice cream samples were significantly increased with increasing turmeric powder addition. The exceptions are samples T0 and T0p where a* values were lower than the control sample, indicating a tendency for green colourations.

Chroma ( C*) is a quantitative attribute of colour and refers to the saturation of a colour. The C* value is the distance from the lightness axis: the higher the value, the higher the intensity of colour of the sample perceived by the human eye. On the other hand, hue ( h*) is a qualitative attribute of colour and refers to the shade of colour: the angle value defines red (0°, + a*), yellow (90°, + b*), green (180°, - a*) and blue (270°, - b*) colour (Pathare et al., 2013). C* and h* values for control ice cream samples, as shown in Table 4, were 8.84 and 104.86, respectively. The addition of spiced powder to ice cream significantly (p<0.05) increased chroma values from 8.84 to 70.53, enhancing colour saturation, and decreased hue values of ice creams from 104.86 to 83.15, changing colour to the reddish region. There were no significant (p>0.05) differences between the series with and without black pepper supplementation in terms of those two parameters.

Whiteness ( WI) and yellowness ( YI) indices are important visual quality characteristics for dairy products, correlating closely with consumers’ preferences for white and yellow colours, respectively (Milovanovic et al., 2020). The decrease of the L* value and increase in the a* and b* values of flavoured ice creams are related to the decrease of whiteness and increase of yellowness index, as shown in Table 4. The addition of turmeric significantly (p<0.05) influenced these indices, while no significant differences (p>0.05) were observed between series with and without black pepper. Maximum yellowness and minimum whiteness values were observed in samples with 2.0 % turmeric powder (T2 and T2p).

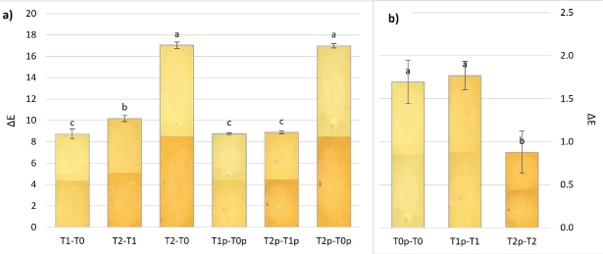

The total colour difference is the colour change calculated as the modulus of the distance vector between the initial colour values and the actual colour coordinates. Differences in perceivable colour can be analytically classified as small differences, not visible to the human eye (ΔE < 1.5); distinct, not considered significant to the human eye (1.5 < ΔE < 3); and very distinct, visible to the human eye (ΔE > 3) (Pathare et al., 2013). Colour differences between the control sample and fortified samples (Table 4) ranged from 56.61 to 63.56, indicating an evident difference in colour caused by the addition of turmeric, and turmeric and black pepper to ice creams. This is expected since turmeric spice is usually utilized as a natural food colourant.

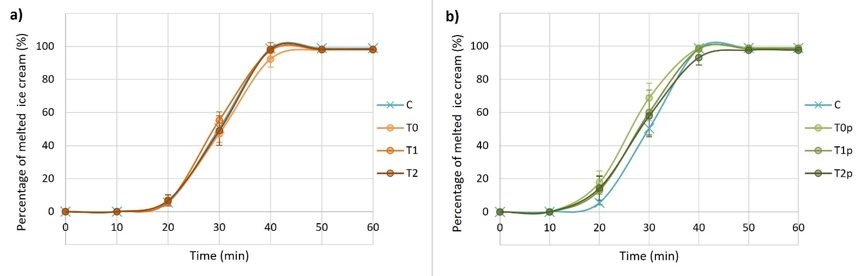

The influence of the amount of turmeric added on the colour differences of ice cream is shown in Figure 4a. The total colour difference between samples with medium and lowest turmeric content (T0 and T1, and T0p and T1p) and between those with highest and middle proportion (T1 and T2, and T1p and T2) ranges from 8.72 to 10.18, while the difference between samples with the highest and lowest turmeric level (T0 and T2, and T0p and T2p) was significantly (p<0.05) higher, 16.98 -17.04. Such a considerable difference in colour is easily noticeable to the human eye.

Figure 4. Colour differences (ΔE) between flavoured ice cream samples: a) comparison between samples with different proportions of turmeric, b) comparison between samples with and without the addition of black pepper (T0, T1, T2 - samples with 0.5 %;1.0 % and 2.0 % of turmeric, p - samples with added 0.02 % black pepper. Data are expressed as mean ± SD. Bars with different superscripts are significantly different using the Tukey HSD test (p<0.05))

Conversely, the addition of black pepper did not visibly change the colour of the samples. Values of differences (Figure 4b) were very small, ranging from 0.88 to 1.77, which is close to the limit values that the human eye can detect.

These findings are in agreement with those obtained by Aumpa et al. (2022), Yeon et al. (2017), and Khawsud et al. (2020) for ice cream samples enriched with a mix of cinnamon and black pepper, and fermented black pepper. They reported a decrease of L* and WI and an increase of a* and b* of samples. Similar changes in colour parameters were also reported when turmeric or curcumin was added to yogurt or milk reported by Gao et al. (2022) and Guerra et al. (2022).

The contribution of turmeric powder to the colour properties of samples was related to deep, yellow colour pigment curcumin, and the colour of black pepper is the result of oxidation of colourless phenolic compounds present in its skin (Balasubramanian et al., 2016).

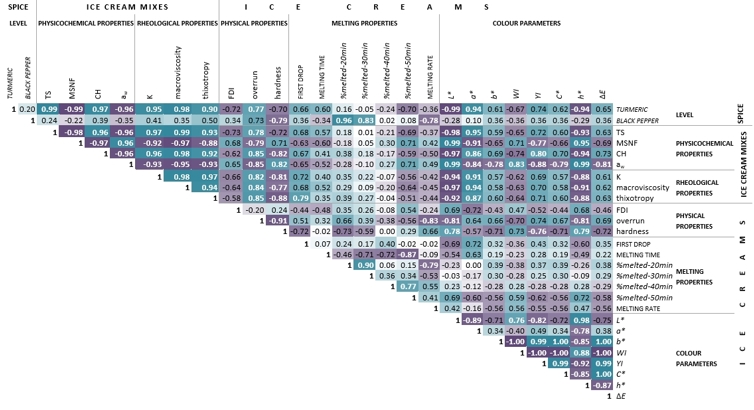

Correlation between properties of ice cream mixes and ice creams

The relationship between the level of added spices, physicochemical and rheological properties of ice cream mixes and physical, melting and colour properties of ice creams are shown in Table 5. Some significant correlations are previously listed in the Results and Discussion section, next to the results to which they relate.

Table 5. Pearson’s correlation coefficients heat map between the properties of mixes and ice creams

*Blue boxes indicate positive correlations, and purple negative correlations. Values in white and bold indicate a significant correlation (p<0.05)

Overall, it can be seen, that addition of turmeric showed a high positive correlation with the total solids (0.993), the carbohydrate level (0.968), rheological parameters, the consistency coefficient, macro viscosity and thixotropy (0.946, 0.984, and 0.899 respectively) as well as the reddens value (0.940). A negative correlation was found with the overrun (-0.770), the lightness and the hue colour parameters (-0.986; -0,935 respectively). Black pepper supplementation had a negative correlation with hardness (-0-793) and melting rate (-0.785). The results show that the physical and colour properties of the fortified ice creams were significantly affected by the composition and viscosity of ice cream mixes, as a result of the addition of spices. It is interesting that no significant correlation between the melting properties of ice creams and properties of mixes was observed in this study, except a positive correlation between the first drop and thixotropy. More extensive research is needed to explain this phenomenon.

Conclusions

Curcumin is a powerful natural functional ingredient of turmeric, but when taken orally is poorly absorbed and rapidly metabolized and eliminated. In this research, to overcome these issues, black pepper was added into one series of samples, as it has been previously reported that piperine enhanced curcumin bioavailability. The present study demonstrated that the addition of turmeric powder, as well as a mix of turmeric powder and black pepper, had positive effects on some physicochemical properties of the ice cream: overrun, hardness, and melting resistance. Although the results of this research indicate that these spices can be used in order to produce ice cream with acceptable physicochemical properties, further extensive investigation should be conducted. However, the results of this study can be applied in the development of new innovative ice creams enriched with functional additives, turmeric and black pepper.

Fizikalno-kemijska svojstva sladoleda s dodatkom kurkume i crnog papra

Sažetak

U ovom radu ispitivan je utjecaj dodatka praha kurkume te njene kombinacije s crnim paprom na fizikalno-kemijska svojstva sladoleda. Proizvedeni uzorci s dodatkom kurkume u koncentracijama 0,5 %, 1,0 % i 2,0 %, sa ili bez dodatka 0,02 % crnog papra, uspoređivani su s kontrolnim sladoledom. Provedena su ispitivanja kemijskog sastava, pH vrijednosti, aktiviteta vode (aw), reoloških svojstava, razine povećanja volumena, indeksa destabilizacije masti, tvrdoće, svojstava topljenja te parametara boje uzoraka. Rezultati istraživanja pokazali su da dodatak začina značajno povećava pH vrijednosti (od 6,66 do 6,73), udio suhe tvari (od 36,43 do 37,53 %) te udio ugljikohidrata (od 21,47 do 22,53 %). Nadalje, dodatak začina doveo je do povećanja viskoznosti (od 0,44 to 0,70 Pa s) i tiksotropnog ponašanja sladolednih smjesa. Sladoledi obogaćeni začinima imali su veću inkorporaciju zraka, niži stupanj destabilizacije masti te mekšu teksturu. Otpornost topljenju bila je poboljšana nakon dodatka začina u sladoled. Dodatak kurkume značajno (p<0,05) je utjecao na parametre boje sladoleda, ali razlike između uzoraka sa i bez dodatka papra nisu zamijećene. Dakle, može se zaključiti da se prah kurkume i crni papar mogu koristiti u proizvodnji funkcionalnog sladoleda koji u konačnici ima prihvatljiva fizikalno-kemijska svojstva.

Ključne riječi: sladoled; prah kurkume; crni papar; fizikalno-kemijska svojstva