Introduction

Snacks are small, packaged, ready-to-eat foods that are consumed rapidly. Snacks, which are popular food items on the market, have a wide range of prices and nutritional values (Yaghi et al., 2022). Most of snacks are based on grains or various starches. Studies on snack foods containing milk protein are extremely scarce (Liu et al., 2018).

During the deep-frying process (160-180 °C), important nutritional components deteriorate, and toxic molecules are formed in the foodstuffs. Fried foods increase the consumption of saturated and trans fatty acids (Dueik and Bouchon, 2011). Excessive fat consumption is also associated with cardiovascular disease and cancer (French et al., 2001). In recent years, there has been an increase in interest in salty snack products that are low-calorie, low-carbohydrate, low-fat, or offer health-promoting benefits. Processes such as drying, extrusion, and baking are applied to achieve these goals. These technologies, however, have not been as successful as expected. Because they still cannot provide the desired quality characteristics of deep-fried foods (Dueik and Bouchon, 2011). Additionally, the development of rancidity in potato chips during the deep-frying procedure reduces their shelf-life. As thus, there is an important need to develop low-fat chips with high sensory qualities in order to increase their acceptability (Joshi et al., 2016). Various studies have been conducted on the development of low-fat snacks (French et al., 2001; Dueik and Bouchon, 2011; Joshi et al., 2016), the investigation of some properties of snacks containing cheese (Rakcejeva et al., 2009; Agarwal et al., 2018; Liu et al., 2018; Uğur, 2019; Albay et al., 2021).

Cheese, rich in protein and with great nutritional value, has been examined as an alternative raw material for chips in this study. Therefore, the study investigated the possibility of producing chips from Dil cheese. Dil cheese is a semi-hard pasta-filata-type cheese with a fibrous texture that is consumed fresh. Longitudinal protein bands have been reported to provide the characteristic fibrous texture of Dil cheese with fat and water between protein fibres, similar to Mozzarella cheese (Kılıc and Isın, 2004). In pasta-filata-type cheeses, the curd is boiled by kneading in hot water or brine, giving it a plastic feature. This type of cheese has stringing, elongation, and melting properties. Fat, physically present in the casein network, significantly affects its texture (Hayaloğlu and Özer, 2021).

The aim of this study was to produce chips without additives by using only Dil cheese with different fat ratios (full-fat, half-fat, and non-fat) and to determine how fat ratios affected the qualities of the chips.

Materials and methods

Dil cheese and cheese chips production

The research was conducted in three replications, with three batches of milk utilized on different days. Raw cow's milk was preheated to 45 °C, then the milk fat ratios (3.37 % full-fat, 1.55 % half-fat, and 0.10 % non-fat) were adjusted and standardized. The milk was then pasteurized for 2 minutes at 72-74 °C and cooled to fermentation temperature (32-35 °C). CaCl2 (20 g/100 L) and 0.3 g mesophilic starter culture (Lactococcus lactis subsp. cremoris, Lactococcus lactis subsp. lactis) (R-707, FD-DVS, Chr Hansen-Denmark) (>107 log cfu/g) were added to the cooled milk. Following that, chymosin rennet (Maxiren® 600-DSM Company-Nedherland) was added to the milk and kept at 32-34 °C for 60 minutes. The formed curd was cut into 1 cm3 pieces and let to collapse on its own for about 10 minutes. Then, the whey was removed. The curd was put under pressure and left for fermentation at an internal temperature of 30±1 °C. Fermentation was ended when the acidity reached 75 °SH and the pH ranged between 4.9 and 5.2. The curd obtained was cut into small pieces and boiled in hot water (83-85 °C). For boiling water, 5 % salt was added to 20 liters of water. After boiling, kneading was made for 5 minutes. Boiled and kneaded curd is extended as a rope and cut by giving it shape. Produced Dil cheeses were left to rest and then vacuum packaged and stored at +4±1 °C (Üçüncü, 2015).

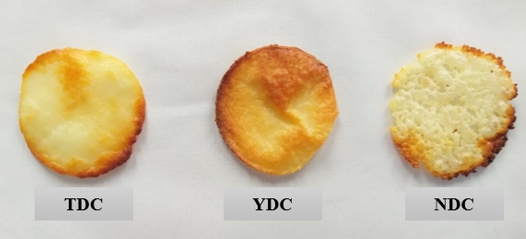

Dil cheeses with different fat ratios were grated and made into dough. After the dough was thinned to 0.6±0.1 cm, it was given the shape of round chips. The chips doughs were pre-dryed (55 °C, 90 minutes) in the drying oven (Wiseven, WOF-155, Korea) and then dried at 180 °C for 6 minutes. The obtained full-fat (TDC), half-fat (YDC), and non-fat (NDC) Dil cheese chips (Figure 1) were packed in transparent vacuum bags with the vacuum setting turned off. The chips were stored at +4±1 °C for one day and analyzed on the 1st day.

Figure 1. Cheese chips produced from Dil cheeses with different fat ratios ( TDC: Full-fat Dil cheese chips, YDC: Half-fat Dil cheese chips, NDC: Non-fat Dil cheese chips)

Raw milk analysis and Dil cheese analysis

Specific gravity, pH, titration acidity (% LA), dry matter (%), fat (%), and ash (%) analyses of raw cow's milk were made (AOAC, 1997).

Titration acidity (% LA), dry matter (%), ash (%), fat (%) (AOAC, 1997), and salt (%) values (Kılıc and Isın, 2004) of Dil cheeses were analysed. The pH values of the samples were determined with a digital pH meter (WTW pH 315, Weilheim, Germany). The Novasina brand water activity device (Lab Touch-aw, Lachen, Switzerland) was used to detect the water activity values of the cheeses. The colour measurement of the cheeses was made at three different points on three randomly selected samples. Colour values (L*, a*, and b*) were determined using the Minolta Chroma Meter (CR-400 Konica Minolta, Inc., Japan).

Dil cheeses were cut into small peaces (36x36x25 mm) for the texture profile analysis. The texture profile analysis was conducted at 20±2 °C using a 50 kg load cell and a 3/4" stainless ball probe (6 mm) (Stable Micro Systems) numbered P/0.75S in a texture analyzer (Texture Stable Micro Systems, TA-XT Plus, UK). During the analysis, at least three measurements were made from each sample using a 10 mm distance (the distance between the probe and the cheese surface), 30 % compression and a probe speed of 1 mm/s (Albay et al., 2021). Hardness, springiness, cohesiveness, gumminess, chewiness, and resilience parameters of the samples were determined.

Cheese chips analysis

Physicochemical analysis

The sample was prepared by adding 2 g of cheese chips to distilled water to make a total volume of 10 mL. The calibrated electrode was put direct into the homogenized sample, then the reading was taken when the pH level remained steady (Khalil et al., 2023). The pH values of the chips were determined using a WTW pH 315 digital pH meter (Weilhelm, Germany), and the titration acidity values were detected as % lactic acid (AOAC, 1997). The dry matter content was analysed by the gravimetric method, the fat content (%) by the Gerber method, the ash content (%) by the gravimetric method after burning the samples at 550 °C in an ash furnace (Nüve, MF 120, Ankara, Turkiye) (AOAC, 2000), and the salt content by the Mohr titration method (Albay et al., 2021). The water activity values were determined with a Novasina brand water activity device (Lab Touch-aw, Lachen, Switzerland).

Colour analysis and texture analysis

Colour measurements were taken from three different points on both surfaces of three randomly selected samples to determine the colour values (L*, a*, and b*) of the chips. The colour values of the samples were determined using a Minolta CR-400 Chroma Meter (Konica Minolta, Inc. Japan).

Texture analysis was performed using a texture analyzer from Texture Stable Micro Systems (TA-XT Plus, UK) with a 5 kg load cell. Five samples from each chips group were analysed. The three-point bend test was applied using the three-point bend rig probe. In texture analysis, 7 mm distance (distance between probe-chips surfaces) and 1 mm/s probe speed values were used (Albay et al., 2021). The maximum force applied to the chips was associated with the hardness of the chips and the deformation value at which the maximum force was applied was associated with the fracturability of the chips. The hardness (g) and fracturability (mm) values were determined by texture analysis.

Volatile aroma components analysis

Analysis of volatile components was performed by solid-phase microextraction (SPME) method according to Yang and Peppard (1994). For analysis, cheese chips were first stored at -20 °C. 3.0 g of the samples were taken in a 15 mL fibre-free silicone septal vial (Supelco 27159 15 mL clear PTFE / silicone septa cap) and heated at 50 °C for 15 minutes. In the extraction process, fibree-vial injection of 75 µm carboxen®/polydimethylsiloxane (CAR/PDMS) (Fused Silica, Supelco Ltd., Bellefonte, PA, USA) was used. The fibre was kept in the headspace for 30 minutes at 50 °C to allow the aroma substances to pass through the fibre structure. The desorption of volatile compounds was conducted in the GC-MS system and kept at 250 °C for 5 minutes. The gas chromatography system (Shimadzu GC-2010) and the mass spectrometry system (Shimadzu MS-QP 5050, Shimadzu Corporation, Kyoto, Japan) were used to determine volatile aroma compounds. The Rx-5sil MS column (30 m x 0.25 mm, i=0.25 um film thickness; Restek, Bellefonte, catalog No:13623, PA, USA) was utilized to separate the compounds.

The applied furnace temperature was initially kept at 40°C for 2 minutes and increased to 250 °C at a rate of 4 °C per minute. It was held at this temperature for 5 min. Helium was used as the carrier gas, and the flow rate was set at 1.61 mL/min. A GC-MS solution was used for data processing. GC-MS analysis was performed in the scanning mode set between 40-300 amu. Volatile compounds were identified by comparing their Retention Index (RI) and mass spectra with analytical standards and validated with Wiley-NIST (National Institute of Standards and Technology), Tutor, and FFNSC (Flavor and Fragrance Natural and Synthetic) mass spectra libraries and RI values. The RI was calculated using an alkane series for each compound.

Microbiological analysis

The Potato Dextrose Agar medium (Merck, Germany) was used to determine the number of yeast molds in cheese chips. For this, 1 mL of the prepared 1:10 dilution was inoculated onto the medium using the spreading method. The petri dishes were incubated at 25 °C for 4-5 days. For coliform detection, 1 mL of a 1:10 dilution was taken and inoculated in Eosin Methylen-Blue Lactose Sucrose medium (Merck, Germany) by the spreading method. For 48 hours, petri dishes were incubated at 37 °C. Colonies growing on petri plates were counted according to Halkman (2005).

Sensory analysis

A panel of 10 panelists (4 women and 6 men) aged 25-30 years conducted sensory analyses of chips. The chips kept to room temperature. Chips were served in random order, each identified by a three-digit random code. Panelists were told to rinse their mouths with water between sample evaluations. Before starting to evaluate the samples, the panelists received training. Two separate tests were applied for sensory analysis. In the first test, the chips were evaluated overall in terms of colour and appearance, texture and crispness, taste, odour, and general acceptability. The second test used a hedonic scoring system with scores from 1 (extremely disliked) to 9 (extremely liked). To assess hardness, the instruction was to bite forcefully with the teeth and score the felt resistance. To score clarity, the aim was to evaluate the amount and quality, deformability and fragility of the sound produced by chewing (Lawless and Heymann, 2010).

Statistical analysis

SPSS (Ver. 22.0) statistical program was used to evaluate the study results, and the results were determined by Tukey multiple comparison analysis (Duzgunes et al., 1987).

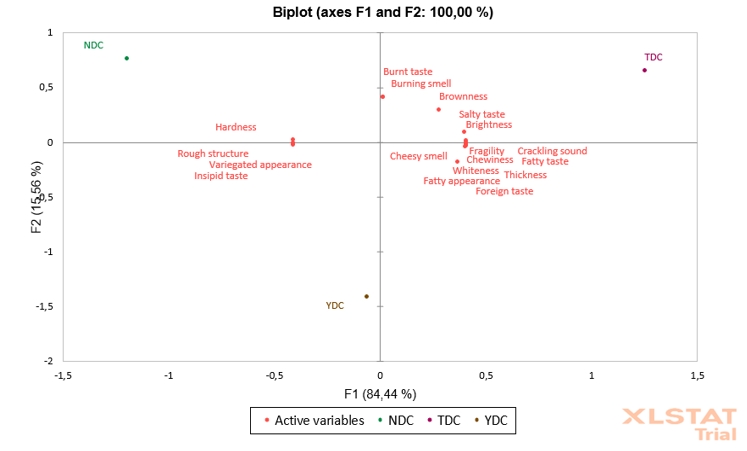

The principle component analysis (PCA) analyse was used in this work to create a visual representation of the similarity or distance pattern between a set of objects and to minimize the dimensions of the data using the Xlstat trial version (XLSTAT 2023.2.1413.1413).

Results and discussion

Raw milk and Dil cheese analysis results

Raw cow's milk had the specific gravity, pH, and titration acidity values of 1.032 g/cm3, 6.93, and 0.16 %, respectively. After fat standardization, the dry matter values of full-fat, half-fat, and non-fat raw milk were determined to be 12.61 %, 11.47 %, and 9.34 %, respectively. At the same time, the fat values were 3.37 %, 1.55 %, and 0.10 %, and the ash values were 0.62 %, 0.92 %, and 0.99 %, respectively. Full-fat raw milk used in production had compatible dry matter (%) and titration acidity (%) values with the Turkish Food Codex Communiqué (TFC, 2000). The specific gravity, dry matter, and fat values of full-fat raw milk, as well as the ash values of half-fat raw milk, were similar to those found in another study on Dil cheese (Uysal, 2008).

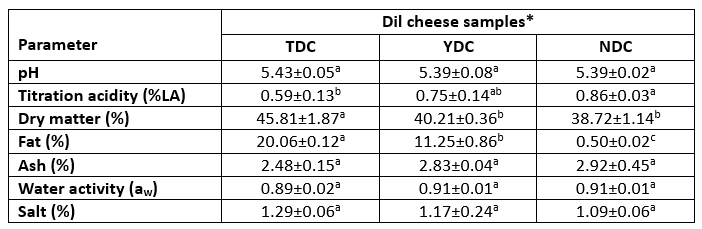

Table 1. Physicochemical analysis of Dil cheeses with different fat ratios

*TDC: Full-fat Dil cheese, YDC: Half-fat Dil cheese, NDC: Non-fat Dil cheese

Physicochemical analysis results of Dil cheeses with different fat contents are presented in Table 1. The titratable acidity values of the cheese samples were 0.59 %, 0.75 %, and 0.86 % in full-fat, half-fat, and non-fat samples, respectively; as the fat content of the cheese reduced, the titratable acidity value increased (p<0.05). The pH value in the reduced-fat samples was lower than partially in the full-fat sample. The dry matter values of the cheese samples ranged 45.81% in the full-fat sample, 40.21 % in the half-fat sample, and 38.72 % in the non-fat sample. As the fat content of the cheese samples decreased the values of ash and water activity increased, while dry matter and salt decreased. The fat and salt ratios in the full-fat cheese determined in this study were close to the ratios determined by Kılıc and Isın (2004). Koca (2002) reported that in reduced-fat Kashar cheeses, the salt content decreases as the fat content decreases, which was associated to the water content in cheeses. The pH, titration acidity, and salt values analysed in all samples, and the dry matter and fat ratios found in full-fat and half-fat samples were previously determined by Koçak et al. (1997) and were similar to the values found for Dil cheese sold on the market.

L*, a*, and b* values were determined to be 83.84±0.08, -3.30±0.07, and 11.54±0.03 in full-fat samples; 83.18±0.27, -3.28±0.00, and 10.97±0.47 in half-fat samples; and 77.78±1.04, -3.80±0.19, and 11.43±0.00 in non-fat samples, respectively, based on the colour analysis findings of Dil cheeses. The full-fat sample were yellower, and the yellow colour of cheese decreases with fat reduction.

The hardness values of the full-fat, half-fat, and non-fat cheeses were 2894.70 g, 2095.89 g, and 1701.01 g, respectively, using the texture profile analysis. The hardness values found in this investigation for half-fat and non-fat cheeses were similar to the hardness values determined by Uğur (2019) in Dil cheese chips dough (13.29-22.79 N). The springiness, cohesiveness, gumminess, chewiness, and resilience values of cheeses were found to vary in the ranges of 0.99-1.02, 0.87-0.99, 1481.63-2638.85, 1519.50-2626.75, and 0.61-0.67, respectively. The hardness, cohesiveness, gumminess, chewiness, and resilience values of the samples were determined to decrease with the decrease in fat content, but the springiness value increased. Reducing the fat content increases the density of the protein network and reduces the moisture / protein ratio of the cheese. Thus, an increase in hardness occurs in reduced-fat cheeses. Similarly, Khanal et al. (2018) reported that the hardness of the cheese texture increased with fat reduction. Kahyaoglu et al. (2005) stated that the springiness of Gaziantep cheese increased with the decrease in the fat content, and a more flexible protein network that formed may cause this by reducing the fat.

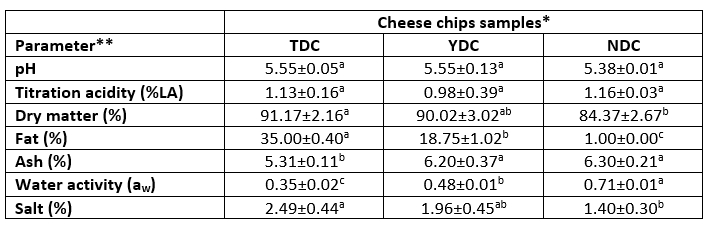

Table 2. Physicochemical analysis of cheese chips produced from Dil cheeses with different fat ratios

*TDC: Full-fat Dil cheese chips, YDC: Half-fat Dil cheese chips, NDC: Non-fat Dil cheese chips

**a-c: Different letters indicate that the difference is statistically significant (p<0.05).

Cheese chips analysis results

Physicochemical properties

Table 2 shows that the statistical differences between the chips were significant (p<0.05) for fat, ash, salt, dry matter, and water activity levels, but not for pH or titration acidity. The pH and titration acidity values varied between 5.38-5.55 and 0.98-1.16 %, respectively. Similar results were obtained with the pH and titration acidity values determined in Dil cheese chips by Uğur (2019). Full-fat, half-fat, and non-fat chips had fat percentages of 35.00 %, 18.75 %, and 1.00 %, respectively. The fat content of fried potato chips available from various brands in the market is reported to vary between 35.00-36.00 % (Joshi et al., 2016). The fat level of the full-fat chips was comparable to that of the commercial products. Furthermore, it was determined that half-fat and non-fat chips had approximately 47 % and 97 % less fat than commercial products, respectively.

Ash and water activity values increased with the decrease of fat content in chips (p<0.05). Additionally, as the fat content decreased, the salt content of the chips decreased, and the salt value varied between 1.40 % and 2.49 %. The salt content of the samples changed depending to the salt content of the cheese, which served as the chips' raw material. The ash value were lower than in the other cheese chips study (Albay et al., 2021). Furthermore, the salt values of non-fat chips were lower and full-fat and half-fat chips to be higher than the salt values (1.54-1.82 %) in the other study. The water activity values of the full-fat and half-fat samples and the fat ratio of the full-fat sample resulted in similar values to those determined in other studies (Uğur, 2019; Albay et al., 2021). Furthermore, cheese puffs with a fat content of 1.4 % were obtained from cheese with a fat content of 0.5 %. Studying the drying of Cheddar cheese in a vacuum microwave dryer, Rakcejeva et al. (2009) found that the fat content in the dried product decreased 1.2 times, while the protein content increased 1.4 times compared to the non-dried cheese. The observed decrease in moisture content based on dry matter was higher and the value of dried cheese decreased 4.4 times.

Colour properties

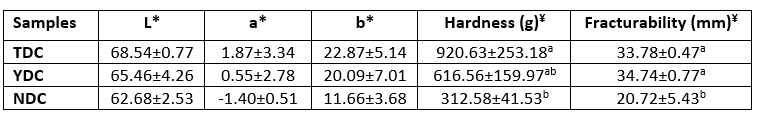

The yellow colour formed as a result of the Maillard reaction is the colour accepted by consumers in potato chips. The increase in L* and b* values and the decrease in a* value in potato chips mean that the ideal golden yellow colour appears (Koklamaz, 2013). The statistical difference between chips was not significant for the colour values (Table 3). The L* values of full-fat, half-fat, and non-fat chips were 68.54, 65.46 and 62.68, respectively. While the a* values ranged from -1.40 to 1.87, the colour values of b* varied between 11.66 and 22.87. Although the effect of the fat ratio on the colour values was statistically insignificant, it was observed that the colour values L*, a*, and b* partially decreased as the fat ratio decreased. In this case, yellower and brighter-coloured full-fat chips were obtained, followed by half-fat chips. The L* and b* values were found to be lower than the values determined by Koklamaz (2013) in potato chips dried by partial frying and the radio frequency method. However, Joshi et al. (2016) obtained similar results with some colour values of microwave-dried low-fat potato chips. Furthermore, L* values were close to the cheese chips study (Albay et al., 2021), and the b* values in full-fat and half-fat chips were found to be close to other studies (Uğur, 2019; Albay et al., 2021).

Table 3. Colour analysis and texture analysis results of cheese chips produced from Dil cheeses with different fat ratios

TDC: Full-fat Dil cheese chips, YDC: Half-fat Dil cheese chips, NDC: Non-fat Dil cheese chips

¥ Different letters indicate that the difference is statistically significant (p<0.05).

Texture properties

Chips texture is usually defined in terms of hardness and crispness. The characteristic crispy texture is one of the most important textural qualities of the final product such as snacks (Duarte-Correa et al., 2020). Full-fat, half-fat, and non-fat chips had hardness values of 920.63 g, 616.56 g, and 312.58 g, respectively, and fracturability values of 33.78 mm, 34.74 mm, and 20.72 mm (Table 3). The full-fat chips were more fragile and harder than the other samples. The hardness and fracturability of the chips decreased as fat content reduced (p<0.05). The fracturability findings of the full-fat and half-fat chips in this investigation closely matched those of Uğur's (2019) Dil cheese chips study. In comparison to the prior research on cheese chips (Albay et al., 2021), the full-fat and half-fat chips hardness values analysed in the present study were higher and their fracturability values were lower. Joshi et al. (2016) reported that the average hardness of commercially available chips (Lay's classic salted) was 456.03 g. This shows that the cheese chips obtained from full-fat and half-fat Dil cheese are harder than the commercial products. However, the hardness values (713.80-917.74 g (7-9 N)) of the microwave vacuum dried low-fat potato chips (Duarte-Correa et al., 2020) and the hardness value of full-fat chips in this investigation were similar. Additionally, Uğur (2019) determined that Dil cheese chips had a harder texture than Teleme cheese chips and that the fracturability values of both cheese chips were similar. Kita et al. (2007) reported that the frying temperature and oil type influenced the texture and fat content of potato chips. With the increase in the frying temperature, the fat absorption in the chips decreased, and accordingly, the hardness of the chips decreased. According to the findings of this and previous studies, the texture of the chips was affected by the type of raw material, fat content, cooking method, and temperature, and the hardness and fracturability of the chips reduced as fat level decreased.

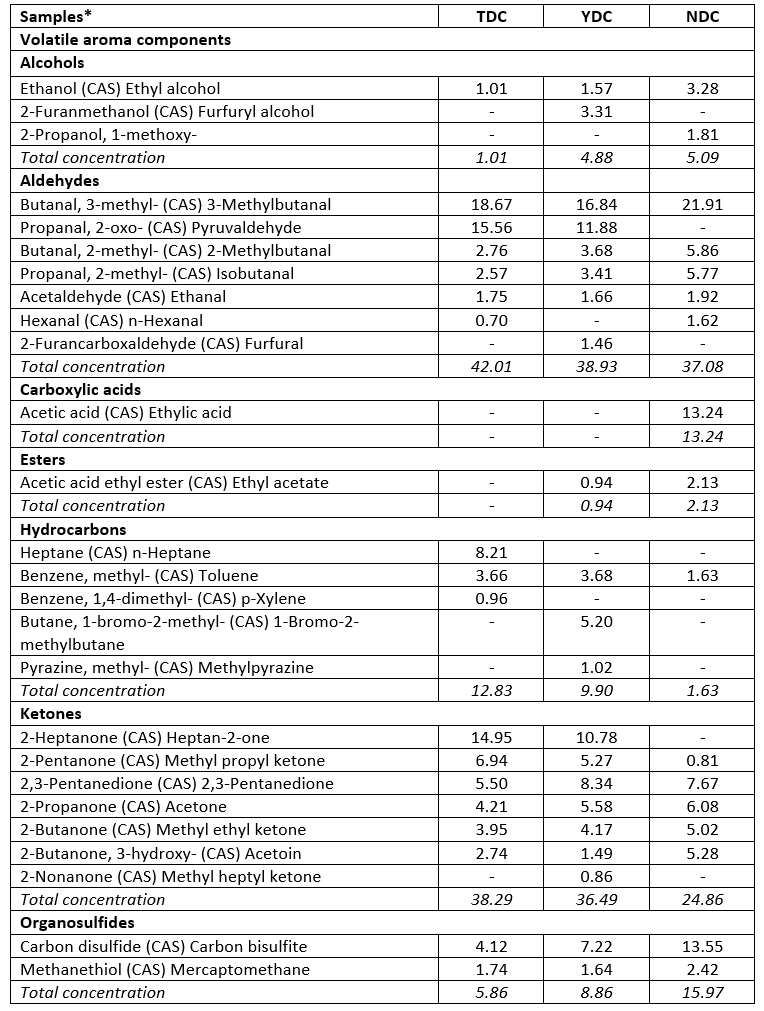

Volatile aroma components

A total of 18 volatile components were found in full-fat cheese chips, 21 volatile components in half-fat chips, and 17 volatile components in non-fat chips (Table 4).

Table 4. Volatile aroma components of cheese chips produced from Dil cheeses with different fat ratios

*TDC: Full-fat Dil cheese chips, YDC: Half-fat Dil cheese chips, NDC: Non-fat Dil cheese chips

Alcohols

The total alcohol concentrations of the chips were determined at 1.01 % in full-fat samples, 4.88 % in half-fat samples, and 5.09 % in non-fat samples. Alcohol concentrations increased with the decrease in fat content in chips. Alcohols can be formed as a result of the degradation of aldehydes formed by the Ehrlich-Neubauer metabolic pathway with the alcohol dehydrogenase enzyme or the Strecker degradation of amino acids (Hayaloğlu and Özer, 2021). In this direction, it is believed that as the fat ratio decreases, proteins become more dominant in cheese chips and alcohol formation increases as a result of the mentioned metabolic pathways. All chips included ethanol, and the ethanol concentration increased as the fat content decreased. Ethanol is the result of the citrate metabolism of Lactococcus spp. in cheese (Albay, 2022). Moreover, it was determined that 2-furanmethanol was formed in half-fat chips and 1-methoxy-2-propanol was formed in non-fat chips. Sanches-Silva et al. (2005) identified five alcohol components in potato chips. Strecker degradation has been reported to produce 3-methyl-1-butanol from these components.

Aldehydes

Aldehydes, which are the first main aroma group in all chips, have a strong effect on cheese aroma. Full-fat, half-fat, and non-fat chips had 42.01 %, 38.93 %, and 37.08 % aldehyde, respectively. The total aldehyde concentrations were reduced when the fat ratio decreased. The total concentrations are believed to decrease due to the rapid conversion of aldehydes to alcohol and acids (Hayaloğlu and Özer, 2021). 3-Methylbutanal and pyruvaldehyde were more dominant in full-fat and half-fat chips, and 3-methylbutanal in non-fat chips. In all chips, 2-methylbutanal, 2-methylpropanal, and acetaldehyde were formed. Furthermore, the n-hexanal was detected in both full-fat and non-fat chips, whereas the 2-furancarboxaldehyde was only detected in half-fat chips.

3-Methylbutanal, the first dominant aroma component in all chips, was determined to be 18.67 %, 16.84 %, and 21.91 % in full-fat, half-fat, and non-fat chips, respectively. 3-Methylbutanal is derived from the amino acid leucine. Its main formation is oxidative deamination-decarboxylation through Strecker degradation (Sanches-Silva et al., 2005). Although 3-methylbutanal provides a green malt odour, at low concentrations it has a fruity and delightful odour. The 3-methylbutanal was found to contribute to the aroma of Camembert, Cheddar, and Emmental cheeses (Albay, 2022), which could also be valid in Dil cheeses, consequently contributing to the aroma of cheese chips. Agarwal et al. (2018) identified 3-methylbutanal and 2-methylbutanal aldehydes as specific components in cheese and onion-flavored potato chips. Similar volatile compounds have been reported in other dairy or cheese products, and it has been suggested that these components in potato chips are related to spice.

Pyruvaldehyde, commonly known as methylglyoxal, is the second dominant aroma component in full-fat (15.56 %) and half-fat (11.88 %) chips. Although tasteless, it contributes significantly to the cheesy aroma. Production of methylglyoxal by co-cultures has been associated to strong cheesy aromas, as well as to broth aromas in low-fat cheeses (Law, 1997). The concentrations of 2-methylbutanal and 2-methylpropanal in chips increased as fat content decreased. Aldehyde formation in cheese occurs mainly through amino acid catabolism. 2-Methylbutanal, 3-methylbutanal, and 2-methylpropanal are formed by the catabolism of Val, Ile and Leu amino acids. Acetaldehyde is formed during the fermentation of the amino acid threonine or lactate fermentation (Hayaloğlu and Özer, 2021). The non-fat chips contained the highest concentration of acetaldehyde.

n-Hexanal has been identified in full-fat and non-fat chips. n-Hexanal is formed by the β-oxidation of unsaturated fatty acids and is important for the aroma of Grana Padano and Mozzarella (Albay, 2022). Sanches-Silva et al. (2005) determined aldehyde (19 %) in potato chips and reported that most identified aldehydes were straight-chain aldehydes such as hexanal, heptanal, and decanal. Furthermore, the amount of hexanal in potato chips was reported to increase during storage and was an indicator of lipid oxidation.

Carboxylic acids

Acetic acid was identified only in non-fat chips, with a total concentration of 13.24 %. Furthermore, acetic acid was the non-fat chips' third dominant aroma component. Acetic acid, which results from the activity of lactic acid bacteria, is an important aroma component that plays a role in cheese flavor formation and contributes to the typical pungent aroma of pickled cheeses (Albay, 2022). Acetic acid was determined at high concentrations in pickled cheeses such as White Cheese, Domiati, Feta, and different varieties of cheese such as Cheddar, Emmental, Gruyere, and Roncal (Hayaloğlu and Özer, 2021). Coleman et al. (1981) identified 13 carboxylic acids, including acetic acid, in the aroma of baked potatoes. They reported that acids are formed as products of thermal oxidative decomposition of fat or by amino acid deamination. These acids are reported to have painty, fruity, acidic, and green notes. According to Sanches-Silva et al. (2005), carboxylic acids (65.35 %) are the most important aroma group in potato chips stored for three months. They also reported that carboxylic acids, the end products of lipid oxidation reactions resulting from fat decomposition or amino acid deamination, show an enhanced state of lipid oxidation in potato chips.

Esters

Esters have green and fruity aromas (Coleman et al., 1981; Sanches-Silva et al., 2005). The ester component of ethyl acetate was detected in half-fat and non-fat chips. The total ethyl acetate ester concentrations in half-fat and non-fat chips were 0.94 % and 2.13 %, respectively. The concentration of ethyl acetate, which is not found in full-fat chips, increased with decreasing fat content. Coleman et al. (1981) reported that the esters determined in baked potatoes were formed by the esterification of various alcohols and acids.

Hydrocarbons

Hydrocarbons are the third main aroma group in full-fat and half-fat chips. Hydrocarbons were detected in 12.83 %, 9.90 %, and 1.63 % of full-fat, half-fat, and non-fat chips, respectively. Total hydrocarbon concentrations tended to reduce continuously as fat content decreased. The n-heptane was identified in 8.21 % concentration in the full-fat chips but not in the other cheese chips. All chips contain toluene components. Toluene concentrations were highest in half-fat chips (3.68 %), and lowest in non-fat chips (1.63 %). It can happen by the reduction of carotene in milk or by the use of solvents during aroma analysis (Albay, 2022). Additionally, p-xylene (0.96 %) in full-fat chips and 1-bromo-2-methylbutane (5.20 %) and methylpyrazine (1.02 %) in half-fat chips were detected.

Ketones

Ketones constitute the second main aroma group in all cheese chips. Ketone concentrations were found for 38.29 %, 36.49 %, and 24.86 % in full-fat, half-fat, and non-fat chips, respectively, and total concentrations decreased with reducing fat content. 2-Heptanone is one of the third dominant aroma components in full-fat (14.95 %) and half-fat (10.78 %) chips. Coleman et al. (1981) reported that painty, green, and fruity aromas characterize simple saturated ketones like 2-heptanone. The 2-heptanone contributes to the aroma of Emmental and Gorgonzola cheeses (Albay, 2022). All chips contained 2-pentanone, 2,3-pentandione, acetone, 2-butanone, and acetoin components, but only half-fat chips had 2-nonanone. The acetoin concentration was highest in non-fat chips and lowest in half-fat chips. Acetoin formation is not of fatty acid origin but occurs by the degradation of pyruvate, which is formed as a result of the breakdown of lactose and citrate (Hayaloğlu and Özer, 2021). Sanches-Silva et al. (2005) reported that ketones are the result of the oxidative degradation of unsaturated fatty acids. According to their findings, the unsaturated fatty acids in potato chips are mainly caused by the frying oil (olive oil), and potato chips contain five components of methylketone, including 2-heptanone and 2-nonanone.

Organosulfides

Organosulfides are the third main aroma group of non-fat chips. Organosulfides were determined as 5.86 %, 8.86 %, and 15.97 % in full-fat, half-fat, and non-fat chips, respectively. An increase in organosulfur concentrations was observed with a decrease in fat content. Carbon disulfide and methanethiol were formed in all chips. Carbon disulfide was the non-fat chips' second dominant aroma component (13.55 %). The carbon disulfide concentration increased as the fat content of the chips decreased. The methanethiol concentration was highest in non-fat chips and lowest in half-fat chips. Methanethiol has been reported to be an important compound in determining the flavor of Cheddar cheese. The concentration of methanethiol correlates strongly with the intensity of cheese aroma (Hayaloğlu and Özer, 2021). Agarwal et al. (2018) also identified sulfur compounds such as dipropyl disulfide, dimethyl trisulfides, and methyl-1-propenyl disulfide in cheese and onion flavored potato chips.

Microbiology results

As a result of microbiological analysis, yeast-mold and coliform group bacteria were not found in chips. It is stated that heat treatment applications at 72-75 °C for 15-30 seconds or at 65-68 °C for 20-30 minutes eliminate 99.9 % of pathogenic bacteria, including heat-resistant pathogenic microorganisms detected in raw milk (Hayaloğlu and Özer, 2021). In this study, pre-drying (55 °C, 90 min) and drying (180 °C, 6 min) were applied to the chips dough. Yeast-mold and coliform group bacteria weren't detected in the samples because of the application of high heat in the production of cheese chips.

Figure 2. Principal component analysis (PCA) of samples of full-fat (TDC), half-fat (YDC), and non-fat (NDC) Dil cheese chips

Sensory properties

The colour-appearance (8.81), structure-crispness (7.63), taste-odour (7.59), and general acceptability (8.36) scores of full-fat chips were determined to be higher than other chips, followed by half-fat chips. The scores of these sensory properties declined as fat content was reduced, and non-fat chips scored between 1-4.

Principal component analysis (PCA) was used to analyze the sensory analysis results of chips. The purpose of using this application (PCA) is to carry out a definition and classification study between samples with sensory analysis (Hardness, brightness, burnt taste, whiteness etc.). The first major component accounts for 84.44 % of total variation, whereas the second accounts for 15.56 % (Figure 2). The eigenvalue of the first principal component was determined as 15.200, and the value of the second component was identified as 2.800. As the fat value increases, the burnt taste and odour of the samples increase, while the colour appears browner, and the brightness value and salinity increase. However, full-fat samples have a fatty appearance and odour, and increased chewiness and fragility. Non-fat samples were described as distinctly hard, had a variegated appearance, insipid taste and a rough structure. According to the relevant graph (Figure 2), the sensory properties of the half-fat samples are similar to those of the non-fat samples.

Conclusion

The statistical differences between the chips were significant (p<0.05) for fat, ash, salt, dry matter, and water activity levels. Full-fat, half-fat, and non-fat chips were found to have fat percentages of 35.00 %, 18.75 %, and 1.00 %, respectively. The dry matter levels in the chips decreased with the fat content reduced. Full-fat chips were yellower and brighter in colour, followed by half-fat chips. Also, the decrease in fat content caused a decrease in hardness values. Full-fat and half-fat samples were similar regarding fragility. Similar volatile compounds were more dominant in full-fat and half-fat chips. The general acceptability scores of the full-fat chips were higher, followed by the half-fat chips. Although the use of low-fat cheese raw materials in the chips investigated resulted in some textural and sensory characteristics loss, it can be concluded that non-fat cheeses can be used in the manufacture of chips.

Funding

The study entitled "Effect of string cheese fat ratios on cheese chips properties" by Gülsüm Akçay, was supported by the Scientific and Technological Research Council of Turkiye (TUBITAK), period 2209-A-2020/1 (University Students Domestic Research Projects Support Program), working on projects with the number 1919B012000546. We sincerely thank TUBITAK 2209-A-2020/1.