1. Introduction

Polyphenols are secondary metabolites of plants involved in their structure, defense system, and environmental adaptation, also contributing to organoleptic traits (bitterness, colour, flavour, and odour) (Adebooye et al., 2018; de la Rosa et al., 2019). Since today, over 8000 polyphenols have been identified (Rocchetti et al., 2022), showing immense structural diversity, from simple to complex ones. Still, they all contain one aromatic ring with one or more hydroxyl groups joined. Due to the number and position of hydroxyl groups in their structure, polyphenols have primarily antioxidant and anti-inflammatory properties. Recent research demonstrates that polyphenols as natural antioxidants can also offer preventive and therapeutic effects for cardiovascular diseases, neurodegenerative disorders, type 2 diabetes, cancer, and obesity (Abbas et al., 2017; Cory et al., 2018). Therefore, polyphenols are the most researched biologically active molecules in botany, agriculture, chemistry, and human nutrition. According to our research of Google Scholar databases from the 1900s until today, around 1.000.000 scientific papers referring to polyphenols have been published.

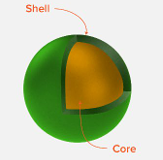

Polyphenols are environmentally unstable. Exposure to oxygen, light, moisture, temperature, and pH values reduces their biological activity or causes complete loss during extraction and various processing procedures into functional products. The most frequently applied methods of polyphenols stabilization are encapsulation methods, i.e., incorporation into protective wall material or capsule shell (Figure 1).

Figure 1. Structure of microcapsules (Orlov, 2021)

Since wall material is a physical barrier against environmental factors and it protects encapsulated polyphenols (core material), encapsulation increases polyphenol stability and application possibility, preserving their functionality and improving their sensory properties (Pashazadeh et al., 2021).

The oldest and still the most significant method for polyphenols encapsulation is spray drying, which converts polyphenols from various liquid extracts into a more stable powder form. The advantages of encapsulated powder are easier handling, i.e., lower storage and transport costs and easier usage than liquid polyphenols extract, improved polyphenols solubility and stability, degradation protection, controlling or delaying the release, masking unappealing tastes or odours and improvement or low changes of colour (Banožić et al., 2023; Furuta and Neoh, 2021).

Selecting the most suitable wall material is one of the most challenging tasks. Wall materials can be broadly categorized into two main groups: conventional and alternative.

2. Conventional wall materials for polyphenols encapsulation by spray drying

Conventional wall materials for polyphenols encapsulation by spray drying include polysaccharides-based materials like native and modified starches, hydrolyzed starches (dextrin, maltodextrin, and cyclodextrin) and natural polysaccharide gums (Samborska et al., 2021). Native and modified starches are generated by plants as carbohydrate reserves from plant roots, stalks, and crop seeds. Dextrin and maltodextrin are produced by partial hydrolysis of starch, while enzymatic modification of starch can lead to cyclodextrins (α-, β-, and γ-cyclodextrin).

Depending on their resources, natural polysaccharide gums can be categorized into four classes: plant (gum arabic) or microbial (xanthan gum) exudate types, seed-derived gums (guar gum), and seaweed gums, e.g., carrageenan (Taheri and Jafari, 2019).

The golden standard wall materials for polyphenols encapsulation by spray drying are maltodextrin, gum arabic, and their mixtures. Maltodextrin is one of the most used conventional wall materials for polyphenols encapsulation by spray drying. It is relatively low cost and has a neutral taste and aroma, so it successfully masks unpleasant taste and odour. Maltodextrin also shows excellent protection against oxidation and thermal degradation of polyphenols. The main disadvantage of maltodextrin as the perfect wall material for polyphenols encapsulation is its low emulsifying potential, which is why it is often used in mixtures with gums, most frequently with gum arabic. Gum arabic is only gum with GRAS status (Generally Recognized as Safe – GRAS) (Patel and Goyal, 2015). It is an edible biopolymer of D-glucuronic acid, L-ramose, D-galactose, and L-arabinose with about 2% protein structure. Low protein content gives it good emulsifying properties and it is an excellent wall material for encapsulating polyphenols. However, the use of gum arabic is limited by its high price and limited availability due to the annual production of 300 g per acacia tree and impurities in the carrier itself (Poshadri and Kuna, 2010).

Over the past decade, there has been a growing trend in using new wall materials as additional compounds or substitutes for conventionally used ones (Samborska et al., 2021).

3. Alternative green wall materials for polyphenols encapsulation by spray drying

Following the sustainable production trends, researchers look for an alternative to conventional wall materials, especially maltodextrin and gum arabic. “Alternative green” refers to the origin of materials derived from by-products and waste. So, green biopolymers are new groups of wall materials. According to their structure, they can be classified as animal-based (whey protein, gelatine, soy protein isolate) or plant-based proteins (gluten, canola, pea, and sesame protein isolate; sunflower, oat, and rice protein, zein), chitosan and polysaccharide dietary fibers (inulin, pectin, β-glucan, soluble soybean polysaccharide) (Coimbra et al., 2021).

Whey protein and gelatine are the most frequently used animal-based green biopolymers for polyphenols encapsulation by spray drying. Whey protein is the main by-product of the cheese industry. It is a blend of predominantly globular proteins, β-lactoglobulin (constituting approximately 50%) and α-lactalbumin (making up around 20%), and other minor constituents like immunoglobulins (10%) and serum albumin (about 8%) of the total whey protein components (Kandasamy et al., 2021). Almost

90% of the milk used in the cheese industry becomes whey, globally, around 100 million tons annually (Buchanan et al., 2023). It has GRAS status, is relatively inexpensive, and is usually used in a mixture with secondary wall material such as maltodextrin. Combinations of whey protein and maltodextrin improve the drying properties and oxidative stability of encapsulated polyphenols (Gimbun et al., 2019; Bušić et al., 2018; Rafiq et al., 2023). As a wall material for encapsulation, whey protein demonstrates outstanding potential in film formation and retention (Coimbra et al., 2021).

Plant-based protein by-products, cereal and oilseed proteins, are extensively used for encapsulation, because they are less allergenic, cheaper, and more abundant in raw materials than animal analogs. For example, wheat gluten is a by-product of starch and gluten-free food industries, cheaper than animal protein, with constant quality and large-scale availability (Samborska et al., 2021).

Chitosan is the world’s most essential and abundant marine biopolymer and the second most abundant polysaccharide after cellulose. The wealthiest and most available source of this natural marine polysaccharide is shrimp waste. Acid demineralization and alkali deproteinization are commonly used to extract chitosan from shrimp waste, followed by bleaching and deacetylation (Said Al Hoqani et al., 2020). Chitosan possesses a notable trait, e.g., it is insoluble in organic solvents and water, but soluble in mild acidic solvents. This unique property makes it an ideal and effective material for encapsulating sensitive core substances, releasing them precisely in target areas like the intestines, where the pH is below 4 (Raza et al., 2020). Due to chitosan’s health benefits, it is used in the food industry, wastewater treatment, agriculture, cosmetics, pharmaceutical, and medical applications (Casadidio et al., 2019; Kabanov and Novinyuk, 2020). Chitosan has proven anticancer (Adhikari and Yadav, 2018), anti-inflammatory (Kim, 2018), anti-Alzheimer (Manek et al., 2020), and antiobesity health benefits (Tao et al., 2021); it reduces the amount of blood cholesterol (both total and low-density cholesterol) and reduces the risk of cardiovascular disease (Naveed et al., 2019).

Dietary fibres as polysaccharide wall material have additional health benefit value to functional products. Fiber compounds, pectin (Freitas et al., 2021), β-glucan (Sengül and Ufuk, 2022), soluble soybean polysaccharide (Liu et al., 2015), and inulin (Shang et al., 2018) also have antioxidant activity. So, using these alternative wall materials to encapsulate polyphenols leads to further health benefits, high encapsulation efficiency, and high shelf life. Pectin gelling, emulsification, and binding abilities make it a promising wall material (Rehman et al., 2019). About 70% of the pectin structure represents

D-galacturonic acid, linked by an α-(1,4) glycosidic bond. Furthermore, pectin contains at least 17 different sugars, mainly L-arabinose and D-galactose (Yapo, 2011). Pectin by-product sources are citrus peels and apple pomace from the waste of the fruit juice industry. Almost 50% of all fruit products are juices, creating only 25 million tons of waste from citrus fruit annually (Kandemir et al., 2022), and around 25–30% of the dry weight of citrus peel is believed to consist of pectin (Dranca and Oroian, 2018).

β-glucan is one of the most significant soluble dietary fibres due to its health benefits to human health. In addition to the already mentioned antioxidant activity, it also lowers total and LDL cholesterol levels, boosts the immune system, influences glycemic response, prevents obesity and cardiovascular diseases, and has anti-inflammatory and anticancer properties (Sengül and Ufuk, 2022). It is composed of

D-glucose monomers linked by β-glycoside bonds. Depending on the origin, β-glucans can be divided into two categories as cereal and non-cereal. Usually, β-glucan by-product sources are oat (Avena sativa L.) bran, containing from 2 to 7%, and barley (Hordeum vulgare L) bran, reaching up to 11% (Goudar et al., 2020; Morales, 2023).

Soluble soybean polysaccharides are waste from soymilk, soy protein isolate, and tofu industry. Soy waste has been produced worldwide since soybean food gained popularity in Western and Asian regions. China only created 2,8 million tons of okara, a soybean waste type, by tofu industries (Asghar et al., 2023). Soluble soybean polysaccharides are composed of a galacturonan backbone of homogalacturonan (α-1,4-galacturonan) and rhamnogalacturonan (repeating units being comprised of α-1,2-rhamnose and α-1,4-galacturonic acid), branched by α-1,4-galactan and α-1,3- or α-1,5-arabinan chains (Tajik et al., 2013). It is suitable for encapsulation due to its film forming and adhesion properties (Grgić et al., 2020).

Inulin is the most frequently used alternative wall material for polyphenols encapsulation by spray drying due to its additional beneficial prebiotic effect on the gut microflora. It also improves calcium absorption and decreases the risk of atherosclerosis and colon cancer (Shoaib et al., 2016). Inulin is a fructooligosaccharide, i.e., it consists of fructose units connected by a β (2-1) bond with glucose at the end of the chain (Bakowska-Barczak and Kolodziejczyk, 2011). Inulin is mainly obtained from chicory root, but alternative sources can be inulin-rich wastes (leaves, bracts of flowers, and stems) from the artichoke canning industry, which represents 70% of the total artichoke biomass (Cavini et al., 2022). Inulin is usually mixed with other wall materials because of lower encapsulation efficiency (Dobrinčić et al., 2020; Gaćina et al., 2022).

5. Conclusion

The green benefits of using alternative wall materials to encapsulate polyphenols by spray drying are their sustainable production from agriculture and food industry by-products and waste and the additional health benefits of produced powders.

Author Contributions: Conceptualization, writing - original draft preparation, writing - review and editing - N. G.

Funding: This research received no external funding.

Acknowledgments: Ante Filipović Grčić graphical designer.

Conflicts of Interest: The authors declare no conflict of interest.